- Course Overview

- Hide/Show Tree Items

- Accessing Commands

- Importing Data

- 3D Model Types

- Definitions

- Case Study: Solids vs. Surfaces

- Creating Solids From Surfaces

- Decomposing a Solid into Surfaces

- Additional Surface Concepts

- Importing Mold Design

- File Translation

- Why Do Imports Fail?

- SOLIDWORKS Import Options

- Case Study: Repairing and Editing Imported Geometry

- Procedures for Rebuilding Fillets

SOLIDWORKS MOLD DESIGN TRAINING

Learn manual mold creation techniques and Mold Tools

OVERVIEW

- CLASSROOM LENGTH: 2 days

- INSTRUCTOR-LED ONLINE LENGTH: 4 days

PREREQUISITES: We recommend completing the SOLIDWORKS Advanced Part Modeling course.

DESCRIPTION: Mold Design Using SOLIDWORKS teaches you several manual mold creation techniques and how to use the Mold Tools in SOLIDWORKS mechanical design automation software.

LESSON PLAN

Lesson 1:

surface concepts and imported geometry

Lesson 2:

core and cavity

- Core and Cavity Mold Design

- SOLIDWORKS Mold Tools

- Case Study: Camera Body

- Mold Analysis Tools

- Analyzing Draft on a Model

- Using the Draft Analysis Tool

- Draft Analysis Options

- Adding Draft

- Scaling the Model

- Establish the Parting Lines

- Shut-Off Surfaces

- Creating the Parting Surface

- Surface Bodies

- Creating the Mold Tooling

- Seeing Inside the Mold

- Interlocking the Mold Tooling

- Creating Part and Assembly Files

Lesson 3:

side cores and PINS

- Additional Mold Tooling

- Case Study: Power Saw Housing

- Trapped Molding Areas

- Side Cores

- Feature Freeze

- Lifters

- Core Pins

- Manual Selction Techniques

- Case Study: Mixer Base

- Modifying Shut-Off Surfaces

- Completing the Tooling

Lesson 4:

advanced parting lines

- Case Study: Manual Parting Line

- Case Study: Splitting a Part

- Exercise 9: Peeler

Lesson 5:

Creating Custom Surfaces For Mold Design

- Surfaces in Mold Making

- Case Study: Plastic Bezel of a Cordless Drill

- Creating New Drafted Faces

- Interlock Surfaces

- Case Study: Router Bottom

Lesson 6:

Advanced Surfacing for Mold Design

- Surface Modeling for Mold Design

- The Mixer

- Case Study: Mixer Rear Housing

- Case Study: Mixer Handle

Lesson 7:

alternate methods for mold design

- Alternate Methods for Mold Design

- Case Study: Using Combine and Split

- Creating a Cavity

- Case Study: Cavity

- Case Study: Using Surfaces

- Techniques for Mold Tooling

Lesson 8:

reusable data

- Reusing Data

- Task Pane

- SOLIDWORKS Resources

- Design Library

- File Explorer

- Case Study: 3D ContentCentral

- Library Features

- Case Study: Create A Library Feature

- Configurations in Library Features

- Case Study: Water Line

- Smart Components

Lesson 9:

completing the mold base

- Case Study: Mold Base

- Organizing the Assembly

- Modifying the Lifters

- Iifter Motion

- Ejector Pins

- Cooling the Mold

- Making the Drawing

- Making Changes

- Completing the Process

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

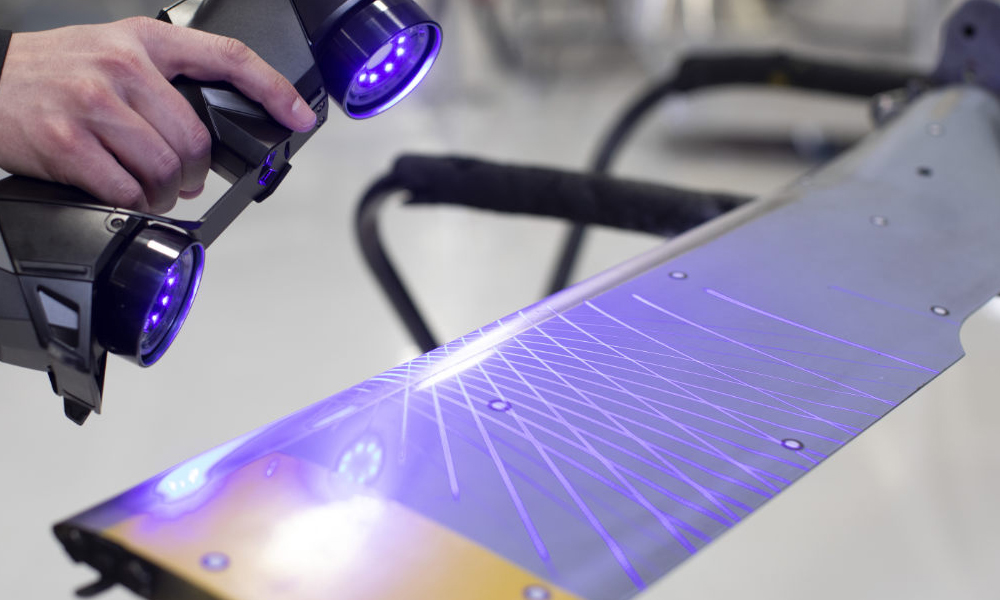

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services