EXALEAD OnePart

Rapidly Locate and Make Sense of Part Details

What is EXALEAD One Part?

EXALEAD OnePart helps engineers and designers quickly decide between design creation or design reuse. It’s a business discovery application that accelerates the reuse of parts, designs, specifications, test results, and related data for engineering, manufacturing, and procurement.

Designers and engineers regularly make critical decisions that can introduce significant costs to your company. Engineers are designing more and more new parts every day. Why don’t they find and reuse similar or equivalent parts that already exist inside your company’s legacy data assets? Because searching for parts and related information is very time-consuming and potentially error-prone.

ACCELERATE THE REUSE OF PARTS

Without an ultra-efficient tool to rapidly find and compare similar parts hidden inside data sources and silos scattered throughout the company, design engineers simply choose to recreate a part rather than spend unproductive time searching. Although they may not realize it, creating new parts impacts the bottom line. Substantial time and costs are incurred if you need to acquire or produce new parts, leading to more production procedures, quality controls, and inventory into stock.

EXALEAD OnePart is a packaged business discovery application that accelerates reuse of parts, designs, specifications, standards, test results, and related data for engineering, manufacturing, and procurement activities. Leveraging proven web semantics, analytics, and big data management technologies of EXALEAD CloudView, OnePart locates information from multiple sources and makes it available instantly.

BENEFITS

Save Time and Money Across the Enterprise

With EXALEAD OnePart, engineers, managers, technicians, and procurement specialists can quickly and easily find and reuse existing parts, product designs, and other related information located anywhere inside the organization, even beyond obvious PDM and PLM repositories. The result: optimized reuse of parts, designs, and related documentation, thus accelerating product development and delivery and decreasing design, material, manufacturing, and storage costs.

REVEAL HIDDEN ASSETS - REUSE LEGACY PARTS - REDUCE DUPLICATE PARTS

- Decrease Time-to-Market and Increase Agility

- Reuse 2D/3D assets from legacy data immediately

- Repurpose past designs hidden from view

- Speed ramp-up time for new projects

- Improve Quality and Decrease Risk

- Leverage past knowledge to enhance products

- Reuse proven and tested designs and parts

- Avoid last-minute design-related issues at launch

- Lower Costs and Free Up Working Capital

- Avoid creating duplicate designs and parts

- Increase knowledge of worker productivity

- Accelerate downstream release processing and logistics

- Decrease redundant inventory and support

FEATURES

Find and Reuse Existing Parts, 2D/3D Designs, and Related Documentation

Based on EXALEAD CloudView proven technology, EXALEAD OnePart enables optimized reuse of parts and related documentation, thus accelerating product development and delivery and decreasing design, material, manufacturing, and storage costs.

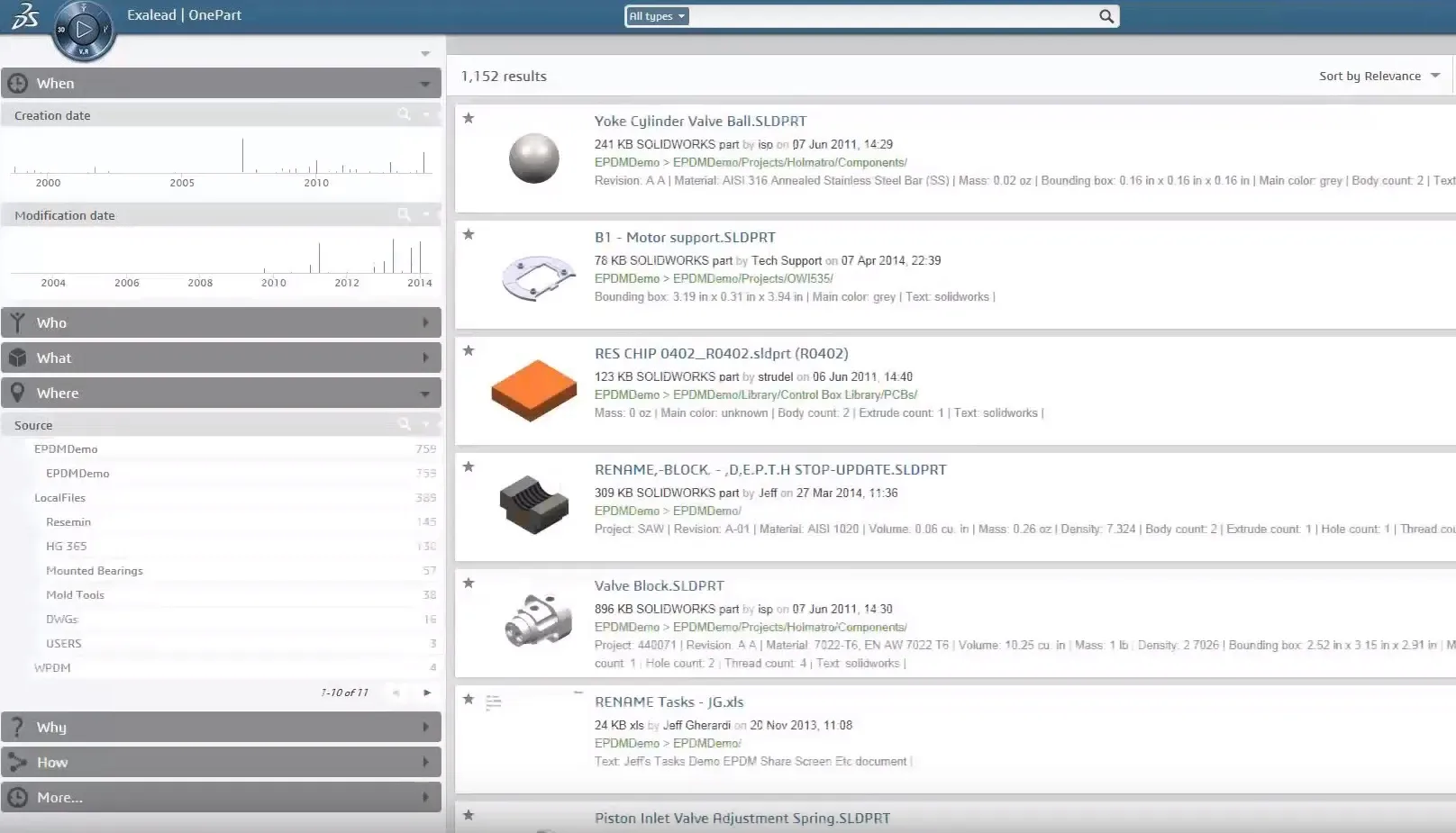

EXALEAD OnePart helps designers and engineers quickly locate reusable parts and determine whether creating a new part (and its incurred costs) is necessary. With just a few clicks, users can explore legacy parts and related 2D/3D designs, gaining immediate insight into vast amounts of previously hidden data. Users can further refine their search using side-by-side comparisons to identify the best part for reuse. When a similar part is discovered, the user can analyze important related documentation like specifications, testing, validation, and certification material in multiple formats (e.g., .xls and .pdf) to facilitate optimal reuse and complete view of the situation.

- Search parts, assemblies, and drawings from most data sources, including CAD providers and from a full-text search bar

- Auto-complete web search functionality speeds user queries

- Navigation into the parent and children relationships of an assembly to converge on the exact right part

- 3D mechanical feature mining (locating parts based on holes, pads, grooves, and others)

- Side-by-side/metadata comparisons to quickly highlight the most relevant part for reuse

- Shape Search to find similar parts based on a known reference part

- User-friendly display of charts and graphs with configurable KPIs for rapid analysis

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services