Available with:

Fortus 450mc / F900

Ultem 1010 (polyetherimide)

– Excellent strength & thermal stability

– Highest heat resistance of any FDM material 421˚F

– Flame, smoke, and toxicity rating

- 14 CFR/FAR 25.853 | ASTM F814/E662

– Available in general purpose or biocompatible grade

- ULTEM 1010CG | NSF51 | ISO10993 Class VI

Potential applications:

– Advanced functional prototypes

– Production parts

– Manufacturing tools and patterns

ultem 1010

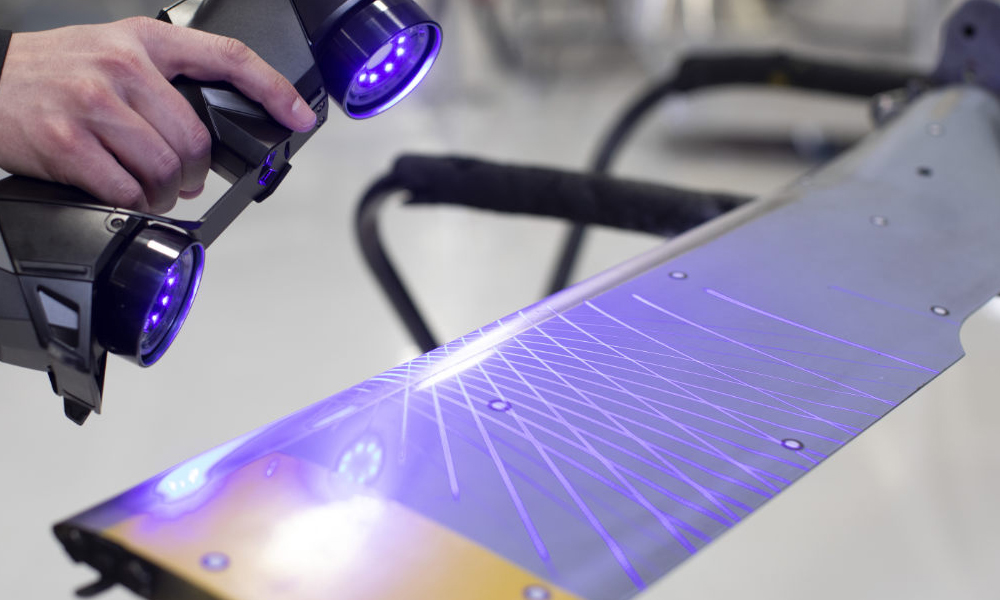

3D print strong, stable parts. ULTEM 1010’s outstanding strength and thermal stability make it ideal for advanced tooling and prototyping applications in the automotive, aerospace, medical, and food-production industries. Its food-contact and biocompatibility certifications expand the use of additive manufacturing into applications like custom food-production tools and autoclave-sterilizable medical devices.

3d pRINTING WITH ultem 1010

Available on the Fortus 450mc and F900 3D Production Systems, ULTEM 1010 resin offers the highest heat resistance, chemical resistance and tensile strength of any FDM thermoplastic. It is the only FDM material with an NSF 51 food-contact certification, and it’s biocompatible with an ISO 10993/USP Class VI certification.

Produce large custom tools for metal, plastic, or composite parts fabrication; 3D print medical tools like surgical guides that can withstand steam autoclaving; build temperature-resistant dies, patterns and fixtures for food production; even manufacture out-of-cabin aerospace components and under-the-hood automotive components including housings, ducts, and semi-structural components.

ULTEM 1010 is available in a natural color and works with improved, easy-to-use breakaway support material.

Additional 3D Printing Resources

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services