SOLIDWORKS PLASTICS PREMIUM

Top Level Injection Molding Analysis Software

The Ultimate Mold Cavity Analysis Simulation Software

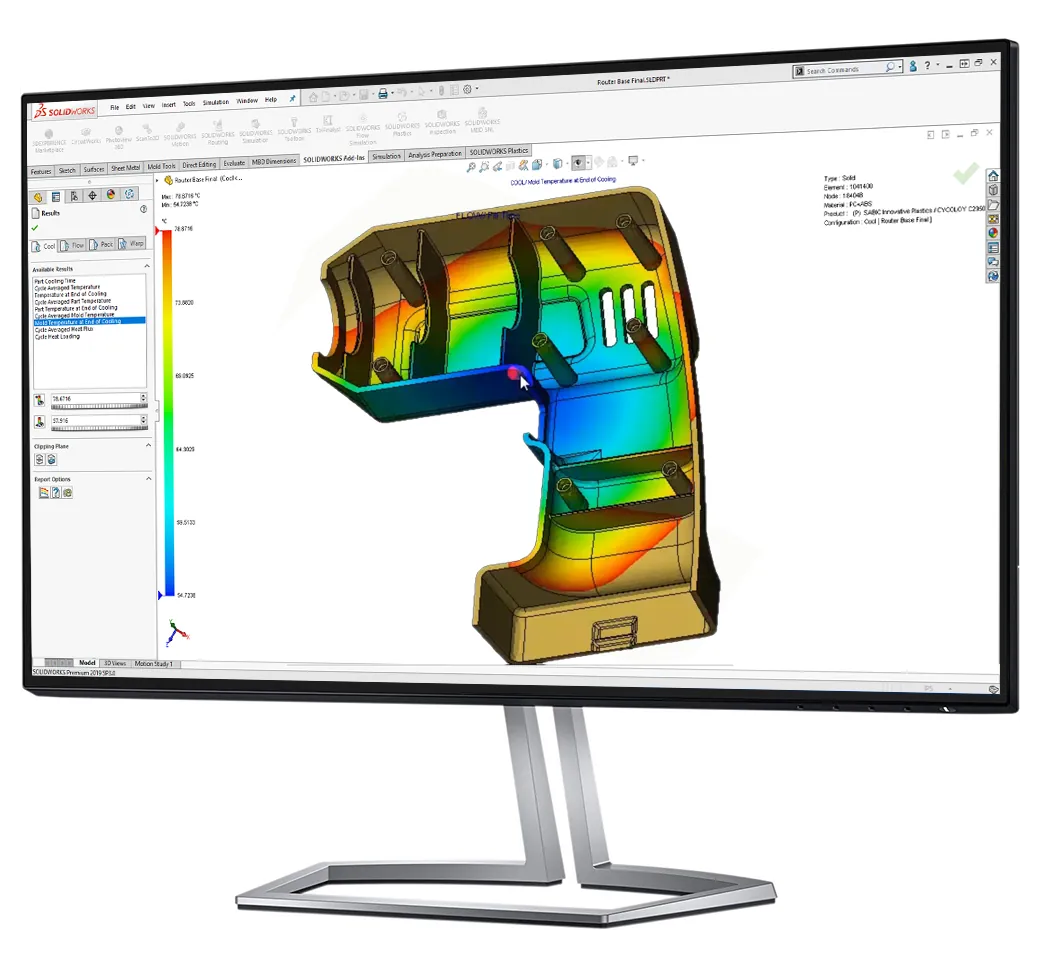

SOLIDWORKS Plastics Premium includes everything in SOLIDWORKS Plastics Professional plus advanced simulation functionality that allows CAE analysts and mold designers to analyze mold cooling line layouts and predict molded part warpage. Users can optimize cooling system, part and mold design to minimize cycle times and decrease manufacturing costs. Additonal features allow designers to change material selection and processing parameters to reduce or eliminate molded part warpage.

TOOLS

SOLIDWORKS Plastics PREMIUM

The ultimate plastic flow simulation testing software available. SOLIDWORKS Plastics Premium includes all the tools of SOLIDWORKS Plastics Standard and Professional but with the addition of advanced features for optimizing your mold cavity design.

Runner Domain Category

Can assign the modeled runner system domain to allow for easy selection for runner condition settings.

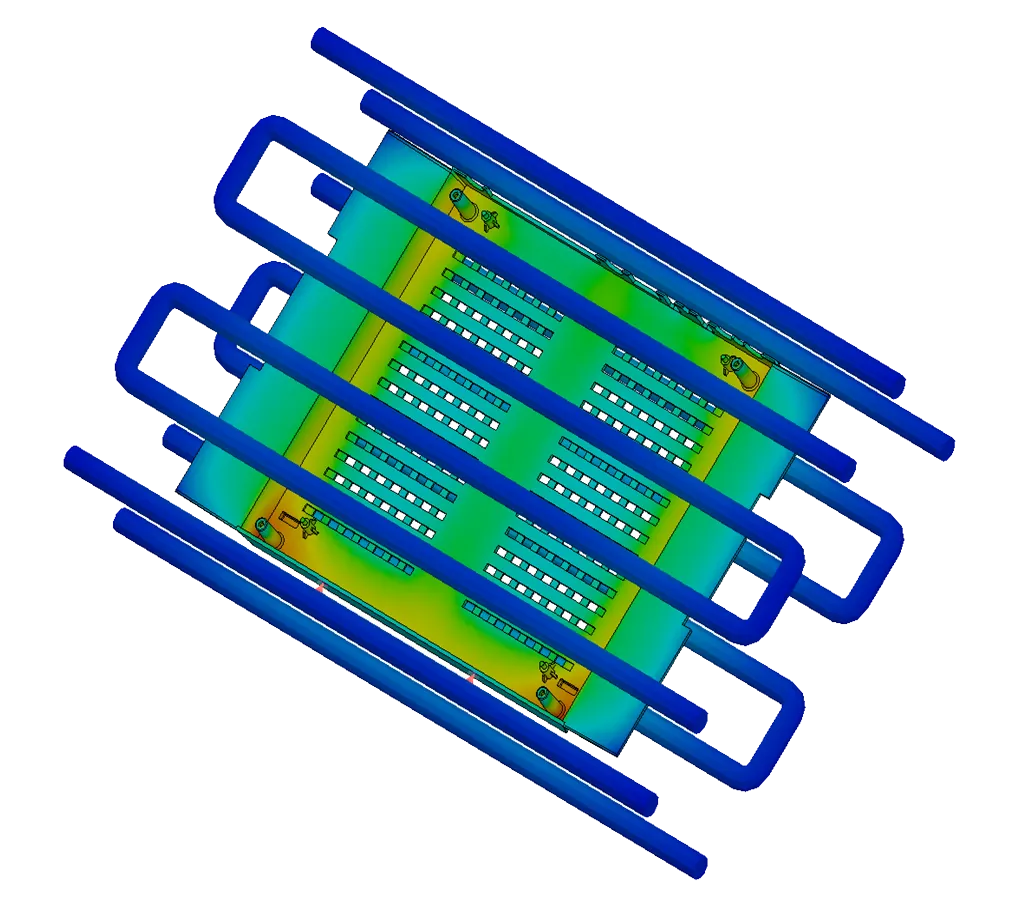

Baffles and Bubblers

Additional cooling channel components used to direct cooling fluid flow closer to the part cavity.

Mold Temperature at Cooling End

Shows the temperature scale on the mold base of the end of the cooling cycle.

Conformal Cooling Channels

The cooling channel follows the shape or profile of the mold core or cavity to perform a uniform cooling process.

Baffles and Bubblers

Additional cooling channel components used to direct cooling fluid flow closer to the part cavity.

Sink Mark Profiles

Displays the location and depth of sink marks on the molded part.

Cooling Lines

Analyzes the effect of cooling channel layout, diameters, temperature, and flow rate.

ALSO INCLUDES:

Design Data Reuse

Materials Database

Meshing

Parallel Computing (Multi-Core)

Filling Phase (1st Stage Injection)

Automatic Gate Location(s)

Instantaneous Fill Time Plot

Sink Mark Analysis

eDrawings Support

Fill Time

Ease of Fill

Symmetry Analysis

Packing Phase (2nd Stage Injection)

Runner Balancing

Runner Design Wizard

Sprues and Runners

Hot and Cold Runners

Multi-Cavity Molds

Results Adviser

Nominal Wall Thickness Adviser

Pressure at End of Fill

Flow Front Temperature

Temperature at End of Fill

Shear Rate

Cooling Time

Weld Lines

Air Traps

Sink Marks

Frozen Layer Fraction at End of Fill

Clamp Force

Cycle Time

Family Molds

Mold Inserts

Volumetric Shrinkage

Density at End of Pack

Exports STL, NASTRAN

Export with Mechanical Properties ABAQUS®, ANSYS®, DigiMat®

Frequently Asked Questions

Other SOLIDWORKS Plastics Packages

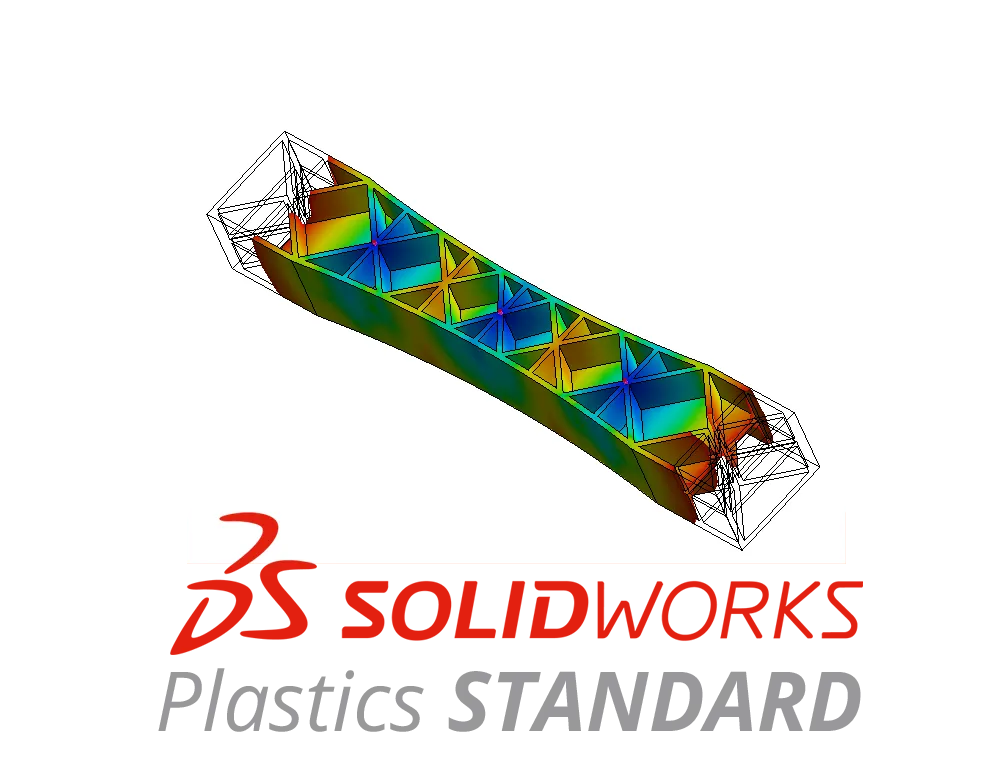

SOLIDWORKS Plastics Standard is the premier mold cavity testing software for part designers. It contains analysis tools that allow plastic part designers to validate and optimize part designs for the injection molding process. This is a great tool for the plastic part designer to use to detect potential molding defects before manufacturing begins.

SOLIDWORKS Plastics Professional is the next step up in mold cavity injection testing. Developed to assist mold designers and mold builders to optimize the mold design that will result in a consistent processing window. Includes additional tools such as multi-cavity design and runner systems to prevent costly rework by minimizing tooling adjustments.

SOLIDWORKS Services:

Utilize GoEngineer’s Award Winning Support & Training for SOLIDWORKS

Award Winning Technical Support

GoEngineer's extensive SOLIDWORKS technical knowledge and world class support can help you succeed with SOLIDWORKS. Our award-winning team is ready to help you with any task you may have. Using state-of-art remote assistant technology software allows our team to solve most issues within one session. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

- 125+Certified Technical Specialists

- Email, Phone and Chat Support Available

- 98% Exceptional Customer Service Rating

PROFESSIONAL SOLIDWORKS TRAINING

GoEngineer offers online and classroom professional SOLIDWORKS training for organizations and individuals. All our instructors are SOLIDWORKS certified and teach thousands of students each year world wide. The curriculum is very diverse with numerous certified SOLIDWORKS courses to choose from. Each student will receive a Course Completion Certificate and preparation materials for SOLIDWORKS certification.

- Increase Your Earning Potential

- Led by Certified SOLIDWORKS Instructors

- Smaller Classes with Focused Attention

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

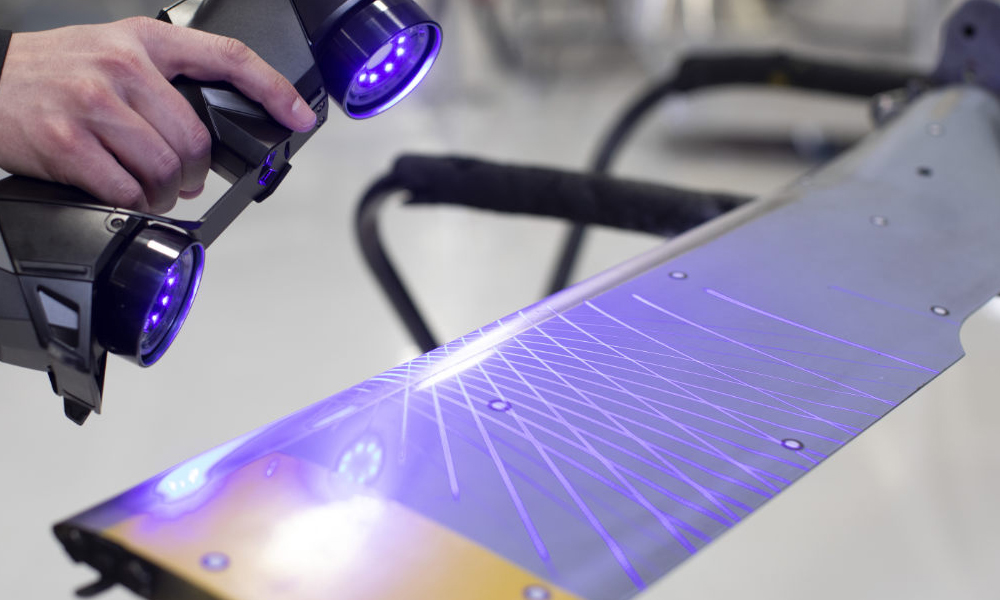

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services