New Stratasys J55 3D Printer: Created for Your Workspace

GoEngineer is proud to announce the launch of a revolutionary new addition to our portfolio of Stratasys PolyJet 3D printers: the Stratasys J55 .

The J55 was engineered from the ground up to offer design studios and educators the full reliability and quality of Stratasys’ PolyJet technology in an easy-to-use, small footprint, ultra-office friendly package – all at an affordable price.

The Stratasys J55 3D Printer is a quantum leap forward for accessible, full-color, Pantone validated 3D printing. With its ability to print in five materials simultaneously, the J55 can create a breathtaking palate of approximately 500,000 distinguishable color combinations. Plus, the J55 can incorporate VeroClear into the digital material matrix to add various levels of transparency to model components, or the new DraftGrey material for rapid printing.

These powerful capabilities yield an unparalleled level of control over your models’ appearance and print times to best serve your needs during every stage of the design process.

Design Software Integration

Another exciting ability available with the new Stratasys J55 that can quickly enhance a designer’s workflow is achieved through Stratasys’ next generation of Design Software Integration. Now, a model rendered in SOLIDWORKS (or other supported CAD software) can be exported as a 3MF file into GrabCAD Print allowing models to more easily be printed with hyper-realistic textures like leather, wood, stone, and more. Whether you are creating rough concept models, detailed designs, or high-fidelity prototypes, the J55 has you covered.

Polar Axis Rotating Build Tray

The new J55 represents the pinnacle achievement of Stratasys’s vision to create a full-color PolyJet 3D Printer specifically for the shared office environment. When starting the J55’s development from scratch, Stratasys’s engineers abandoned the standard “Cartesian Axis” system that typically has been the foundation upon which most 3D printer designs have been built to work from. With the J55, Stratasys has utilized a ground-breaking “Polar Axis” system with a rotating build tray and static print head.

This radical innovation successfully tackles the challenge of maintaining a large build tray while minimizing the machine’s footprint in the office. It also allows the machine to function at the low noise level of 53 decibels, essentially equivalent to your average refrigerator.

UV LED Illumination & PROAERO Air Extractor

The J55 is extremely user friendly with an intuitive GUI presented on a 7in touch screen. For constant and stable performance, zero mechanical calibrations are required! All maintenance procedures are easily handled through the aid of a series of simple “end-to-end” software wizards. Other technological innovations on the J55 to reduce maintenance include the use of new UV LED illumination technology, a new “plug and play” cartridge design, monthly software upgrades, and remote assistance.

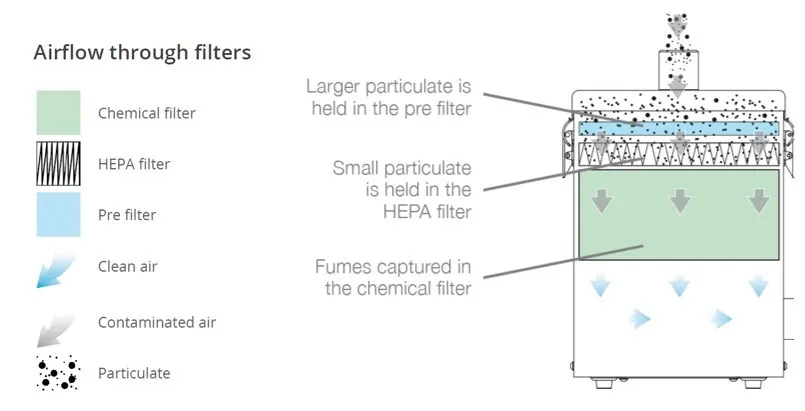

To deal with any odor signatures generated during the printing process, the Stratasys J55 works in conjunction with the optional PROAERO Air Extractor system. This low-noise, low power consumption unit effectively captures fumes from within the printer and returns ultra-clean, filtered air to the operator’s breathing zone.

With Stratasys’s new J55 3D Printer from GoEngineer, there is no need to compromise. Upgrade your design process with high resolution, fast prints, and a full-color range – all integrated into one low power office solution. Now you can transform your workflow without transforming your workspace.

Related Articles

GoEngineer Brings 3D Printing to Michigan

COVID-19: 3D Printing World Responds Quickly to Aid in Battle

About Richard Cromwell

Richard Cromwell is an Additive Manufacturing Applications Engineer based out of Auburn Hills, MI, having recently joined the team in February 2020. He is a Certified Stratasys Applications Engineer and holds a degree in Technological Science with a specialization in CAD from Oakland Community College in Auburn Hills. Before delving fully into his passion for additive manufacturing and 3D CAD modeling, Richard honed his mechanical design, CAM, and custom fabrication skills while working for over a decade as a renowned craftsman creating custom retrofit piano actions for many of the world’s most prized musical instruments.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.