DELMIAWORKS

Manufacturing ERP (Enterprise Resource Planning)

What is DELMIAWORKS?

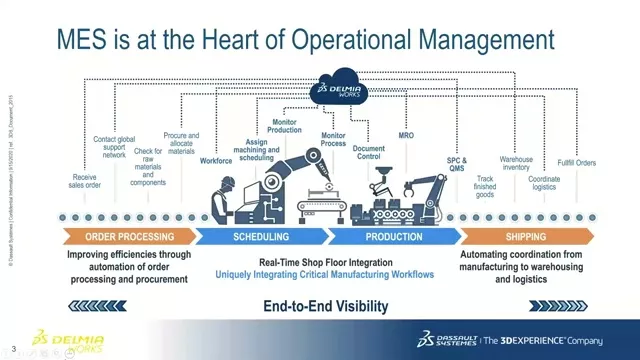

DELMIAWORKS is a Manufacturing ERP (Enterprise Resource Planning). Born on the shop floor, DELMIAWORKS is tailored specifically for a factory environment. Today’s manufacturers face more challenges than ever before. DELMIAWORKS streamlines their processes and provides end-to-end visibility and control from the front door to the back dock. DELMIAWORKS accomplishes this by providing a system for sales, planning, procurement, production, shipping, inventory management, CRM, business intelligence, financing, and more, all in one seamlessly integrated platform.

Putting a dollar figure on ROI

Download the whitepaper to better understand the financial benefits of manufacturing ERP including:

- Saving $150,000 a year by improving inventory turns.

- How eliminating a 5% error in standard costs can result in an additional $700,000 in annual profits

- How improving scheduling accuracy and eliminating unexpected downtime can create $3-5 million a year in opportunities

- How reducing production defect rates can lower the cost of poor quality by up to $600,000 a year

- How reducing quoting errors by 5% can increase profitability by $350,000

don't miss this upcoming webinar!

Smart Manufacturing 101: What is it and how do I get there?

September 14, 2022 at 10am PT

To keep your competitive edge, you have to continue to get smarter on the manufacturing floor. Smart Manufacturing, what does it all mean? How do you get started? What are the steps required to make the transition? Join us as we simplify these steps and walk through how successful companies are navigating their transformation journey today to be the leaders of tomorrow. Here are the key topics around smart manufacturing that will be covered:

- Gather real-time manufacturing floor data

- Gain manufacturing visibility

- Production flow & WIP

- Measure and Improve OEE

- Take control of raw materials, scrap & inventory

- Use real-time data to drive your business

Register now to learn more about navigating and transforming your manufacturing future.

WHY DELMIAWORKS?

Single Platform Lowers Cost

You no longer need to support multiple systems with different touchpoints from different vendors. DELMIAWORKS operates on a single database with a single, intuitive interface for all users.

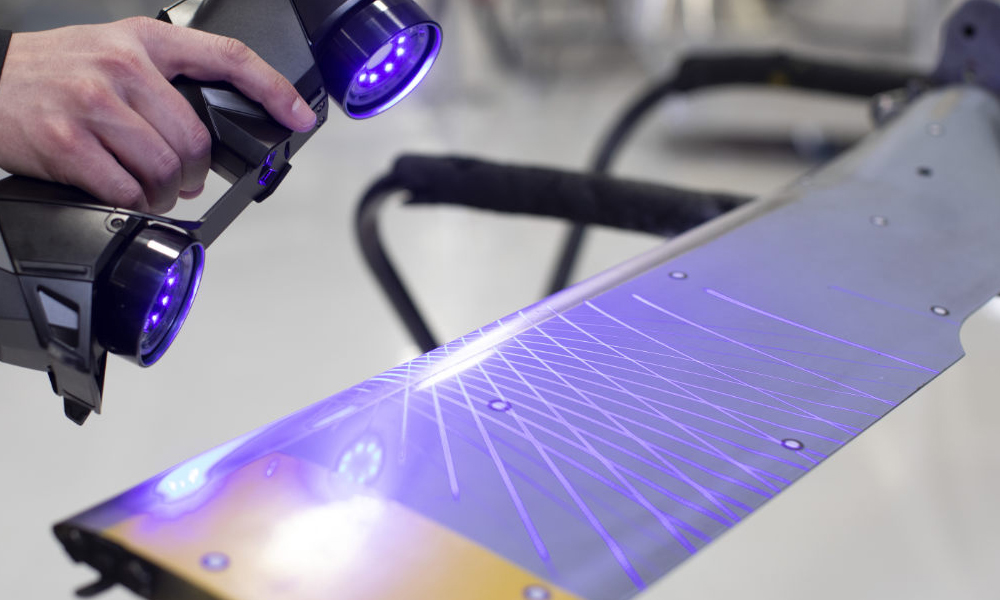

Real-Time Monitorings

Tired of waiting until the end of a shift to understand what is happening on the shop floor? Great decisions are made with great data, real-time monitoring allows the entire company to be connected to the shop floor. Business intelligence dashboards give you a view of what is happening on each machine on your floor, all updated in real-time.

Functionality When You Need It

All the DELMIAWORKS modules and options are designed on the same database, operating as a powerful and cohesive solution. DELMIAWORKS is a Manufacturing ERP system that grows and expands with you.

PROCESSES SUPPORTED

DELMIAWORKS was born on the shop floor, so offering solutions that match your unique business process is in its DNA. Whether you subscribe to a singularly specific manufacturing process or have a multi-layered or multi-process application, DELMIAWORKS offers the tools you need to succeed. Some of the many types of processes we support include:

-

Assembly

-

Blow Molding

-

Die Casting

-

Extrusion

-

Fabrication

-

Injection Molding

-

Machining

-

Master Batching

-

Rotational Molding

-

Stamping

-

Thermoforming

-

Thermoset

-

Welding

-

Capabilities

Frequently Asked Questions

Stop Flying Blind: Gain Visibility into Your Manufacturing Operations with DELMIAWorks

One of the greatest challenges manufacturers face is the lack of visibility into their manufacturing operations. Learn how DELMIAWorks Manufacturing ERP provides that visibility to increase efficiency and profitability by:

- Tracking production status in real-time

- Ensuring material, equipment, and labor are available to meet demand

- Enabling consistent and timely communication across the supply chain

- Identifying bottlenecks and constraints that might affect the production schedule

- Eliminating waste and control costs

- Producing quality parts on time, every time

INDUSTRIES SUPPORTED

Industry-specific intelligence gives DELMIAWORKS the unparalleled ability to handle your unique manufacturing needs. Below is a sample of a few of the industries and why DELMIAWORKS has been designed to be focused on manufacturing.

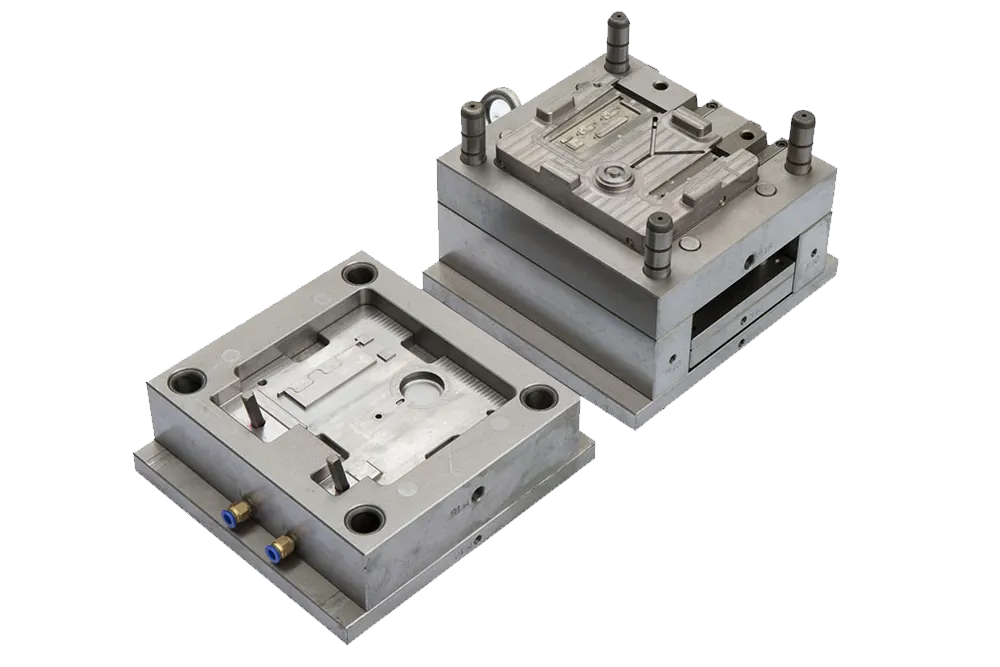

PLASTICS

Manage family tools, multi-level and multi-process BOMs, unique unit of measurement conversions, regrinding and consumption, recipes and blends, and cavitation impacts on production schedules.

From injection molding and extrusion to compounding and thermoforming, DELMIAWORKS helps manage the challenges to ensure on-time part delivery.

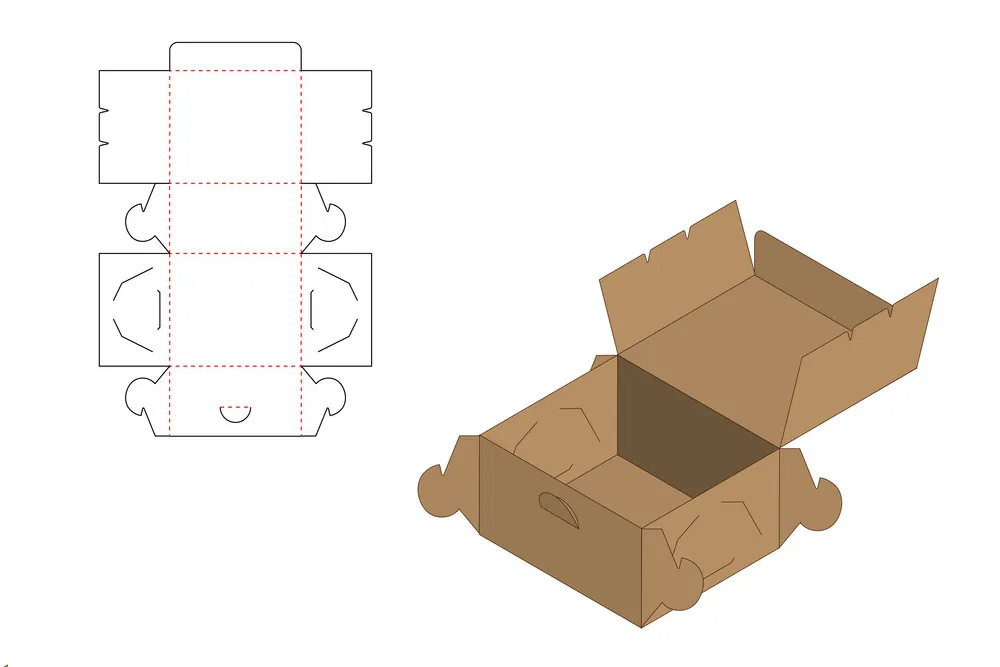

Packaging

It adeptly handles lot and serial traceability, UPC labeling, pack outs, external and internal document control. Unlimited, pre-defined, tool-based BOMs, with the ability to handle your dies and inks, meet the unique needs of your production operations.

You can take a proactive role in tracking and moving inventory with characteristics that limit shelf life. Once the shelf life has expired, the inventory is automatically identified as non-conforming, and alerts are sent out.

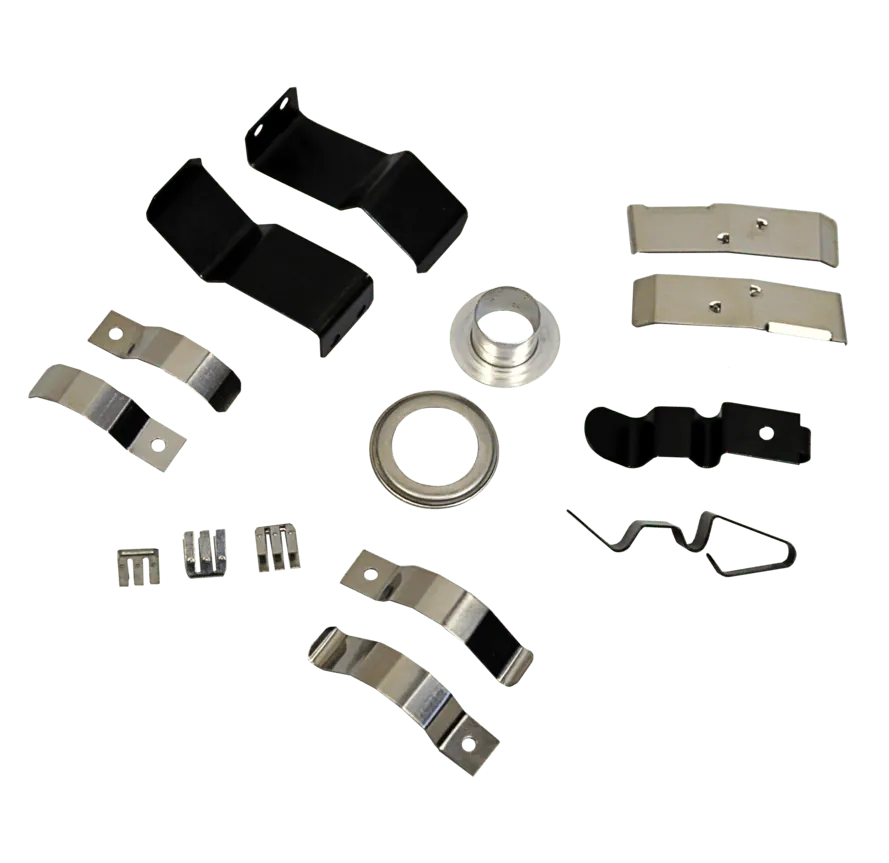

Stamping and Metals

Whether you are machining short-run parts or stamping out 1000 parts per minute, you need a system that keeps you lean and agile. From punching and stamping to casting, brazing, shearing, and spinning (including support for your die and tool maintenance), DELMIAWORKS is specially designed to handle every step in the fabrication process.

Family tool and dies are easily supported, as the system is designed to understand multiple part numbers within the same physical tool. You can also easily track and schedule preventative maintenance and see where out of service tools will have a direct impact on production scheduling.

Putting a dollar figure on ROI

Download the whitepaper to better understand the financial benefites of manufacturing ERP on everyday operations including:

- Saving $150,000 a year by improving inventory turns.

- How eliminating a 5% error in standard costs can result in an additional $700,000 in annual profits

- How improving scheduling accuracy and eliminating unexpected downtime can create $3-5 million a year in opportunities

- How reducing production defect rates can lower the cost of poor quality by up to $600,000 a year

- How reducing quoting errors by 5% can increase profitability by $350,000

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services