- VoluMill Overview

- Case Study: Using VoluMill

- Exercise 2

SOLIDWORKS CAM Professional

Learn how to program CNC Lathe machines, and test run high speed machining with Volumill

OVERVIEW

- INSTRUCTOR-LED ONLINE LENGTH: 4 days

PREREQUISITES: Must complete the SOLIDWORKS CAM Standard Essentials Course before enrolling into CAM Professional.

DESCRIPTION: This course teaches how to use the SOLIDWORKS CAM Professional software to machine parts utilizing advanced functionality such as: CAM or SOLIDWORKS configurations, VoluMill™, mill machining in the context of an assembly, and 3 plus 2 machining. Additionally, the course teaches how to generate, modify and post process 2 axis turning toolpaths used for the machining of SOLIDWORKS part files.

LESSON PLAN

Lesson 1:

SOLIDWORKS CAM Configurations

- SOLIDWORKS CAM Product Review

- SOLIDWORKS CAM Configurations

- Case Study: Using Configurations

- Case Study: Working With CAM Configurations

- Exercise 1

Lesson 2:

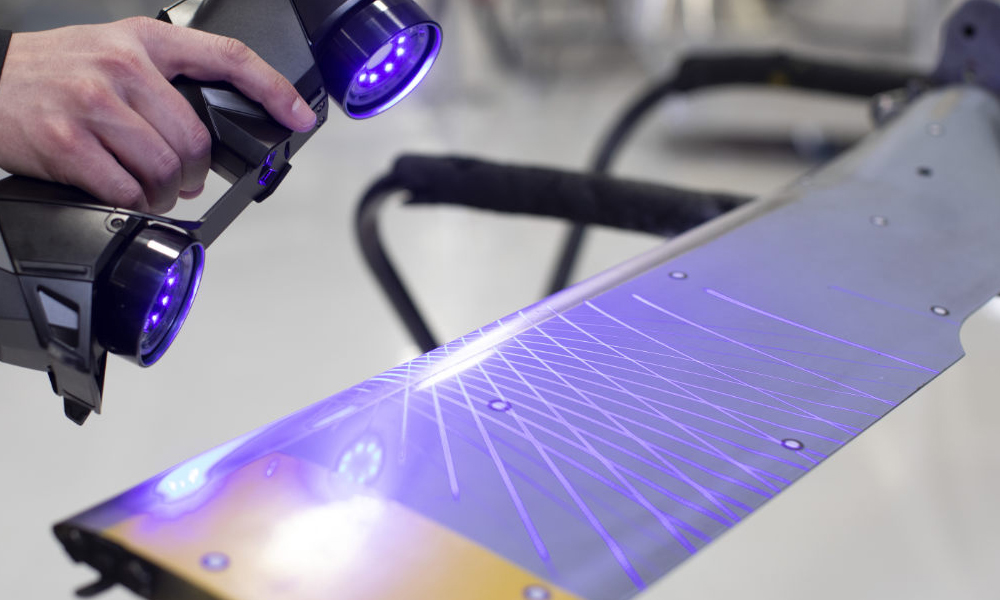

High Speed Machining (VoluMill)

Lesson 3:

Assembly Machining

- SOLIDWORKS CAM Assembly Mode

- Case Study: AM Using a Vise

- Case Study: AM

- Programming with Subroutines

- Case Study: AM Multiple Parts

- Case Study: AM Split Instance

- Exercise 3

- Exercise 4

- Exercise 5

Lesson 4:

3 Plus 2 Machining

- 3 Plus 2 Machining (Indexing)

- Case Study: 3 Plus 2 – Part Machining

- Case Study: Assembly Machining with a Tombstone

- Exercise 6

Lesson 5:

Turning BasicS

- SOLIDWORKS CAM Turning

- Process Overview

- Case Study: Generate Toolpaths and NC Code

- Case Study: Interactive Features and Operations

- Exercise 7

- Exercise 8

Lesson 6:

Chucks, ID Features and Operations

- Section Method

- Case Study: Using Plane Section

- Case Study: Using Double Chucks

- Exercise 9

Lesson 7:

Modifying Feature and Operation Parameters

- Case Study: Custom Chuck, OD and Thread Features

- Exercise 10

Lesson 8:

Probing

- Introduction to Probing

- Probe Operation

- Case Study: Probing Operations – Part 1

- Case Study: Probing Operations – Part 2

- Case Study: Probing Operations – Part 3

- Exercise 11

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services