The Complete Guide to Buying Cadence PCB Design Solutions

A guide to making the right choice between Allegro X and OrCAD X

Find the Right PCB Design Solution

Which Software Tool is Best For Your Needs?

Selecting the best PCB design software for your business depends greatly on the complexity of the PCB you will design and manufacture in the end. Depending on your business requirements, Cadence offers a variety of PCB design solutions from basic to advanced functionality.

Below is a basic overview of the different PCB design software packages we offer. For a more in-depth comparison of the functionality between each tier, review our OrCAD X and Allegro X product matrix.

PCB Design Tools from Cadence

OrCAD X

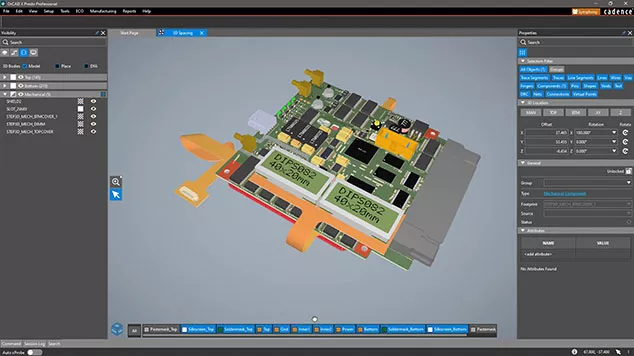

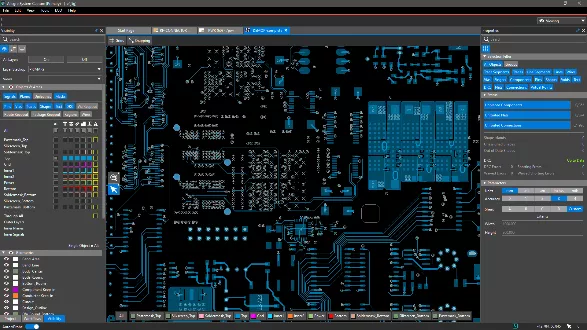

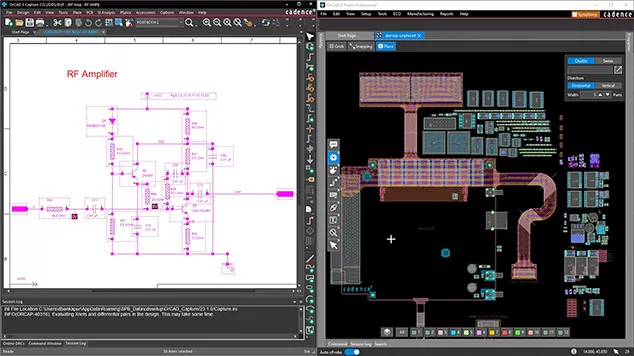

Built upon the well-established OrCAD PCB design software, OrCAD X is the next generation of PCB design. With major improvements in performance, productivity, and integration into other software tools, OrCAD X provides a dependable solution to a large userbase ranging from individuals to a team of engineers.

Ideal for Engineers Who:

- Want a complete front-to-back PCB design software suite that’s reliable and easy to learn

- Are looking to connect SOLIDWORKS or 3DEXPERIENCE

- Want built-in PSpice circuit simulation tools

Allegro X

The Allegro X platform is the highest performance PCB design software Cadence has to offer. Some of the features that the Allegro X platform contains may be better suited for your PCB application.

Ideal for Engineers Who:

- Have complex routing designs and are looking for better suited layout tools

- Designing high-density interconnect (HDI) PCBs

- Require RF or other wireless technology routing and simulation capabilities

CNC Programming Tools from CAMWorks

CAMWorks Standard Bundle

Like all CAMWorks tools, CAMWorks Standard is a Certified Gold Partner of SOLIDWORKS and is fully integrated into the software. CAMWorks Standard features all of the capabilities of SOLIDWORKS CAM Professional, plus additional support for rotary milling.

Ideal for Manufacturers Who Want:

- Seamless integration into SOLIDWORKS 3D CAD

- 2.5-axis turning capabilities

- 3 + 2 milling capabilities

- Support for rotary milling

CAMWorks Premium Bundle

CAMWorks Premium is the ultimate integrated CAM solution for SOLIDWORKS users. This advanced tool combines all of the features in Milling Professional and Turning Professional, along with adding superior 4 & 5-axis simultaneous milling.

Ideal for Manufacturers Who Want:

- Seamless integration into SOLIDWORKS 3D CAD

- Up to 5-axis milling with multi-axis machining

- Support for rotary milling

- Mill-turn (up to 11-axis) and multi-function machining

- Sub-spindle programming

- G-code machine simulation

CAMWorks Turning Professional Bundle

CAMWorks Turning Professional is the ultimate CNC programming solution for advanced turning and mill-turn functions. The software also includes Sync Manager for simultaneous machining and Virtual Machine Standard for full machine simulation with collision detection.

Ideal for Manufacturers Who Want:

- Seamless integration into SOLIDWORKS 3D CAD

- Support for rotary milling

- Mill-turn (up to 11-axis) and multi-function machining

- Sub-spindle programming

- G-code machine simulation

CAMWorks Milling Professional Bundle

CAMWorks Milling Professional is the most advanced 3-axis CNC programming solution available for SOLIDWORKS. It includes advanced 3-axis rough milling with rest machining and VoluMill for high-speed machining. Finishing cycles include Z-level (waterline), flat area, pattern project, constant step-over, pencil milling, and curve project for engraving on 3D surfaces.

Ideal for Manufacturers Who Want:

- Seamless integration into SOLIDWORKS 3D CAD

- 3-axis milling

- Mill-turn and multi-function machining

Specialty CNC Programming Software from CAMWorks

CAMWorks NestingWorks

NestingWorks helps manufacturers to optimize the layout of sheet metal and flat stock designs while supporting the transition from design to manufacturing for sheet metal and flat goods.

Key Benefits of NestingWorks:

- Optimize how parts fit on a shape to produce the maximum number of parts from a single piece of raw material

- Maximize material usage by fitting smaller parts into open areas and cutouts of larger parts of the same thickness

- Automatically group and nest parts of the same thickness

CAMWorks Wire EDM

This specialty CAM tool from CAMWorks was developed specifically for programming 2 through 4-axis Wire EDM CNC machines. Like all CAMWorks products, it fully integrates with SOLIDWORKS.

Key Benefits of Wire EDM:

- Automate the creation of rough, skim, and tab cuts

- Automatically change the processing order options with a single command

- Choose between the output of only rough cuts, only tab cuts, or both

- Easily switch between different machine code outputs

Where Can I Purchase Cadence Software?

Contact Your Cadence Reseller

The only way to buy Cadence products is through a certified reseller like GoEngineer.

Cadence products are sold worldwide through a select network of authorized Cadence partners. Partners also provide additional services, product training, and ongoing support.

For the US market, GoEngineer is one of two Cadence partners and the nation's leading SOLIDWORKS reseller. A Cadence software purchase through GoEngineer will put you in the ideal position to pursue integrated PCB and mechanical design, simulation, manufacturing, and data management.

GoEngineer is the VAR for Cadence and Dassault Systèmes (SOLIDWORKS & CATIA) products throughout the U.S. Browse our locations to find your regional office.

Not located in our territory? Find your national Cadence partner(s) on Cadence's Channel Partner Programs page.

What is Cadence PCB Design SOFTWARE PRICED AT?

How Much Does OrCAD X Cost?

Pricing for OrCAD X starts at $1,280 for a yearly lease, which includes technical support and product updates.

How Much Does Allegro X Cost?

Pricing for Allegro X starts at $4,000 for a yearly lease, which includes technical support and product updates. Perpetual licensing starts at around $12,000, with an optional yearly maintenance price for support and updates.

Are there any Allegro X or OrCAD X Promos?

Check our Cadence promotions page for details on any active promos.

Additional CAM Resources

CAM TRAINING

Utilize GoEngineer's expert CAM instructors to help you understand how to succeed with SOLIDWORKS CAM and CAMWorks

CAM PROMOTIONS

For the most current CAM discounts and promotions available.

CAM Library

View the latest CAM videos, blogs, and techincal articles.

AsK a GOENGINEER EXPERT

Still Have Questions About Our PCB Design Solutions?

Reach out to GoEngineer and one of our

CAMWorks VIDEO Tutorials

How Does it Work?

In this four part CAMWorks video tutorial series we break to the onboarding process with a detailed step-by-step instruction.

SOLIDWORKS CAMWorks Tutorial: Part 1 - Introduction to Feature and Knowledge Based CAM Read More...

SOLIDWORKS CAMWorks Tutorial: Part 2 - The Technology Database Read More...

SOLIDWORKS CAMWorks Tutorial: Part 3 - Programming & Saving Strategies Read More...

SOLIDWORKS CAMWorks Tutorial: Part 4 - Optimize Your Programming with the TechDB Read More...

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

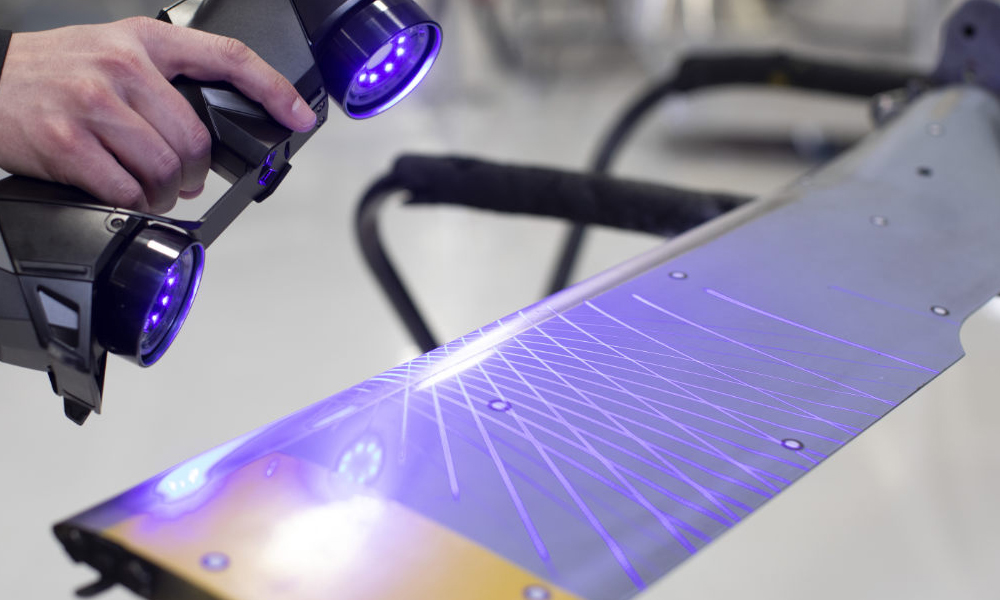

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services