How 3D Printing is Helping Manufacturers Fight Back Against Tariffs

American producers are facing significant challenges due to recent tariffs on imports from Canada, Mexico, and China. These tariffs are an economic punch to a manufacturer’s bottom line. Automotive, Aerospace, Consumer Tech: these industries don't just rely on imports, they're built on them. Rebuilding such fundamental supply chains is not just a source problem; it’s a logistical nightmare that could take years to resolve. As the costs of these changes ripple through production, manufacturers are forced to make difficult decisions.

So, what's the best solution? Absorb the punch? Raise prices and pass the costs through to consumers? Cut corners?

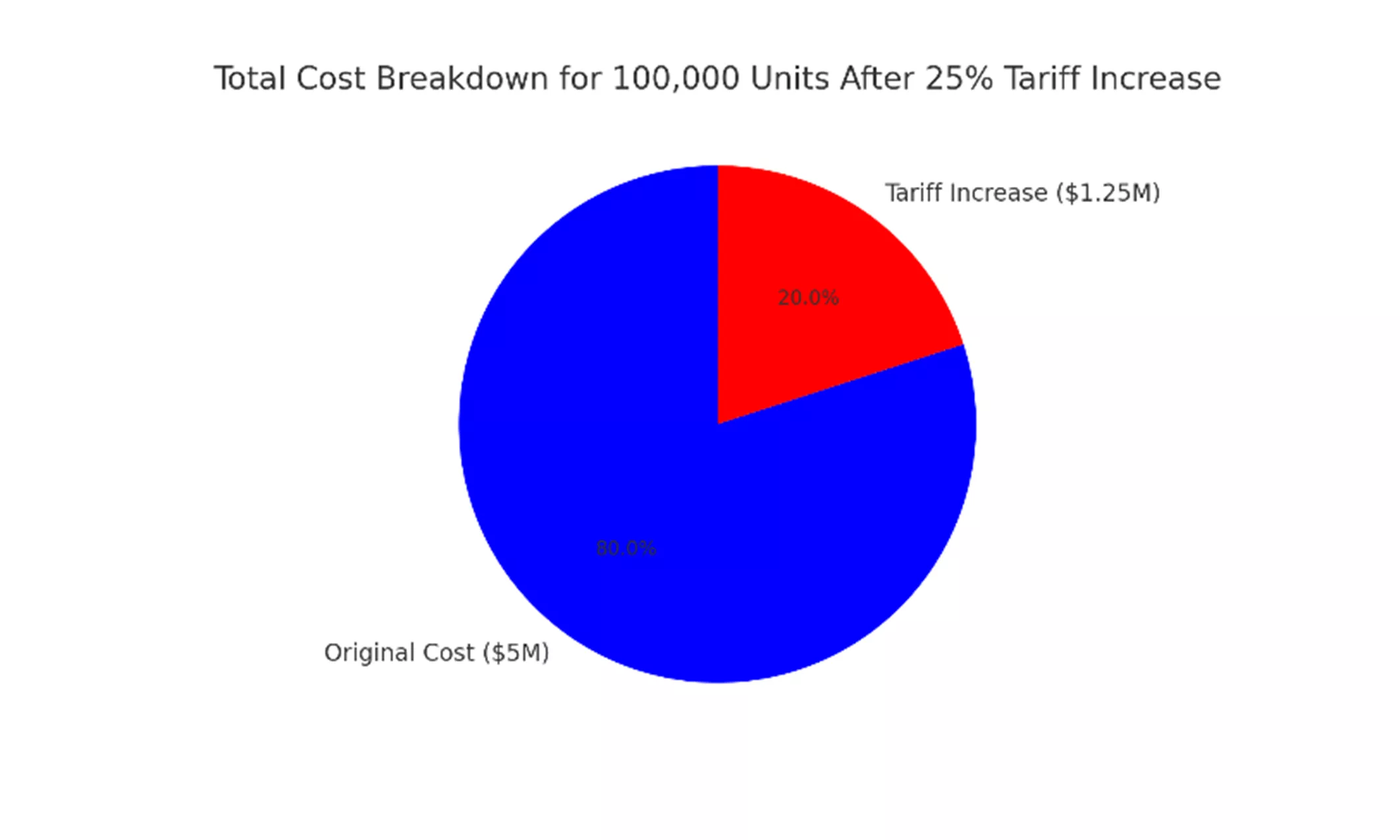

Let's consider the example of a moderately sized auto part importer bringing in aluminum and electronic components from China and Mexico, whose costs rise by millions overnight. If a key component costs $50 and is tariffed by 25%, that is an additional $12.50 per part. Multiply that by 100,000 units a year, and suddenly this company is paying an additional $1.25 million just for this part. Those costs don’t just disappear.

Strategies for Immediate Response

Producers are scrambling to react to rising pipeline costs. But where to start? There are always trade-offs, and the right choice isn’t always obvious. Some things that come to mind:

- Stockpiling inventory before the tariffs take effect

- Finding alternative suppliers outside of Canada, Mexico, and China

- Reshoring production to the U.S. to avoid import fees

- Exploring contract renegotiations to offset higher costs

These strategies could work, but each comes with its downsides. Stockpiling can strain cash flow and lead to warehousing costs.

Outsourcing suppliers to other countries seems logical but new suppliers means time-consuming qualification processes and threats to quality. Bringing production in-house avoids tariffs but increased in-country labor and operating costs could negate savings. Renegotiating contracts can be an uphill battle because suppliers, who have to absorb identical tariffs, have little wiggle room to adjust prices.

While any of these strategies could be effective for short-term damage control, producers need long-term solutions.

The Role of 3D Printing

This is where advanced production techniques, like 3D printing ("Additive Manufacturing"), come into play. Unlike traditional production, embracing 3D printing offers companies the ability to produce parts on demand, which reduces excess inventory, lowers warehousing bills, and minimizes supply chain headaches. And because products can be manufactured locally, this minimizes dependence on imports and avoids price spikes related to tariffs.

But the benefits of 3D printing go beyond dodging tariffs. Its flexibility offers designers the freedom to tweak and revise products in-house without retooling costs. It also provides a backup plan for sourcing challenges. Instead of scrambling to find and qualify new suppliers, manufacturers can fill the gaps in-house while seeking alternative vendors.

For businesses considering reshoring, high labor and facility costs can be a dealbreaker. 3D printing helps offset those expenses by cutting material waste, reducing production time, and eliminating the need for expensive molds and tooling. And when it comes to contract negotiations, having the ability to produce critical parts internally gives manufacturers more leverage to push for better pricing from suppliers.

Real-World Examples

Stratasys recently posted an article citing numerous companies that shifted to 3D printing in-house to help cut costs associated with reliance on imported tooling, components, and other expenses. Some of these companies include:

- By adopting 3D printing, Northrop Grumman reduced rocket motor tooling production time from one year to just six weeks, achieving significant cost savings and increased efficiency.

- TE Connectivity leveraged DLP 3D printing to produce highly accurate electrical connectors for low-volume production, eliminating the need for costly injection molding processes.

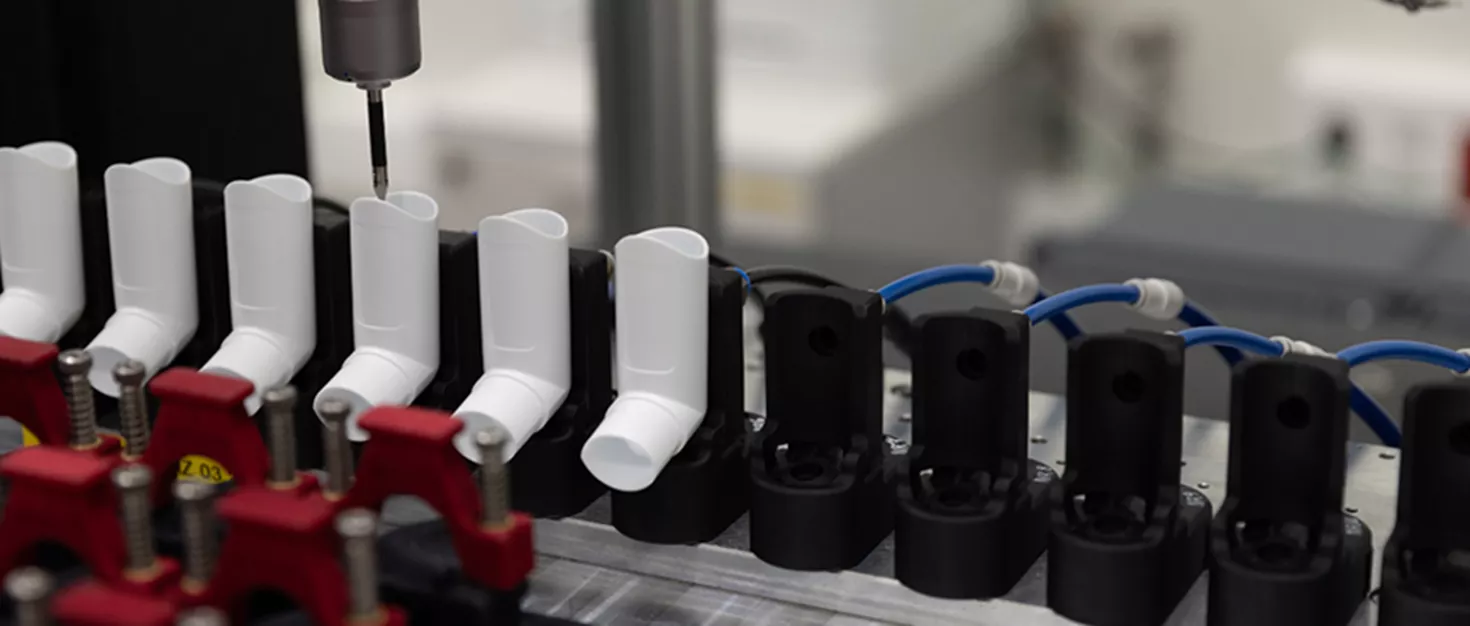

- H&T Presspart utilized Stratasys’ P3™ DLP technology to manufacture pharmaceutical components with extremely tight tolerances. This enabled high precision while maintaining cost-efficiency.

- Roush used Stratasys 3D printing to redesign and manufacture truck camera mounts under a tight deadline, saving 35% in costs compared to traditional manufacturing.

- Unilever adopted 3D printing for prototyping and manufacturing aids, leading to a 40% reduction in lead times and 35% cost savings—enhancing their overall production efficiency.

Conclusion

There’s no one-size-fits-all solution, but manufacturers do have options to stay competitive. Employing a smart mix of methods, including newer production practices like 3D printing, can offset rising prices. Securing alternative suppliers takes time, but having backup sources in place can prevent costly disruptions. Reshoring production may seem expensive, but when paired with automation and additive manufacturing, it can cut long-term reliance on imports. The key is to act now, because procrastination could mean higher costs and tighter margins, ultimately losing out on a window of opportunity.

We want to hear from you. Is your organization adapting to these tariffs in any way? Are you changing suppliers, cutting spending, or coming up with new tech? Let's talk about solutions that will work for your unique situation. Get in touch with GoEngineer to discuss ways additive manufacturing can work in your favor.

3D Printing as a Service

GoEngineer offers comprehensive 3D printing services across multiple U.S. labs, equipped with cutting-edge Stratasys FDM, PolyJet, Stereolithography, P3 and SAF technologies for 3D printed prototypes or production parts. Request your quote online today!

Related Articles

RAPID + TCT 2025 Stratasys Announcements – 4 New Products

Economic Change in Manufacturing Demands a New Approach by Leveraging 3D Printing

GoEngineer Adds Formlabs Products to its Solutions Portfolio

Which Technology is Best for 3D Printing Miniatures?

About Bob Renella

Bob is a Manufacturing Solutions Application Engineer Manager at GoEngineer.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.