Improving the Quality of Industrial Pasta with Simulation

Improve Pasta with Simulation

Pasta production is no different from any other automated or semi-automated production system in that it is performed through a chain of automated operations all working in sequence.

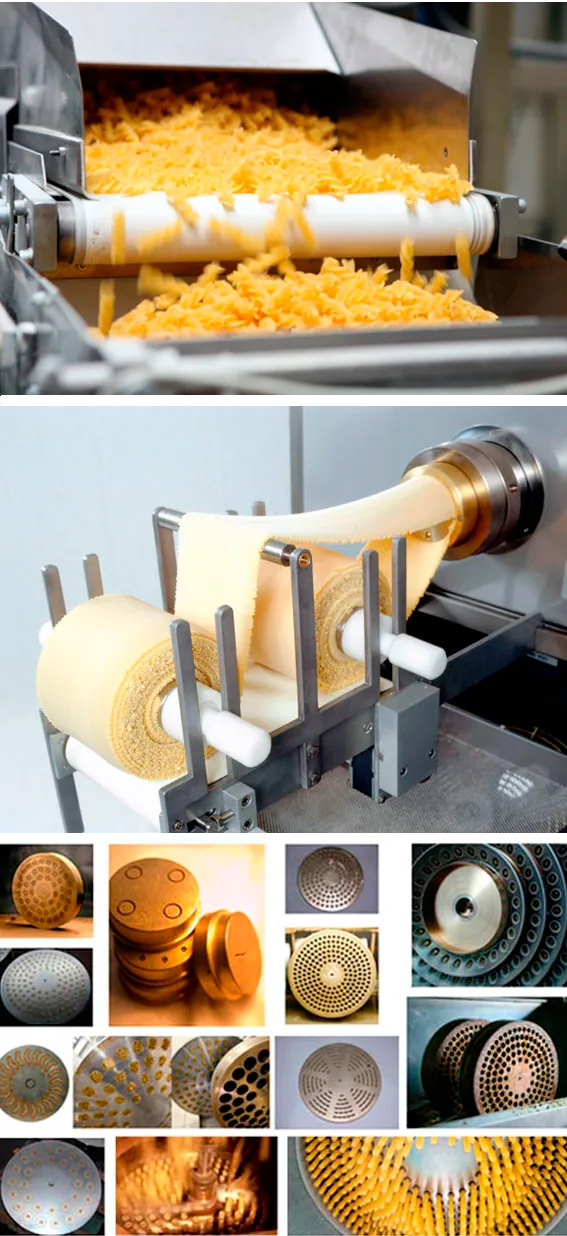

Pasta is produced by mixing milled wheat, water and other optional ingredients to create the dough. Most modern pasta presses are equipped with a vacuum chamber that removes air bubbles from the pasta dough before extrusion takes place. If this process fails, small bubbles will form inside the pasta reducing the quality of the finished product by diminishing its mechanical strength and giving the product a white, chalky appearance.

The dough is then kneaded and moved directly to the extrusion phase where a high capacity auger extruder, equipped with a variety of dies that determine the shape of the pasta, produces the pasta shapes. The auger fits into a grooved extrusion barrel and moves the dough to the extrusion phase generating a great deal of heat due to pressure and frictional forces. In order to dissipate this heat, the extrusion barrels are equipped with a water cooling jacket that maintains the extrusion temperature constant.

After the extrusion phase, pasta is dried. During the drying process, the moisture in the pasta is reduced from approximately 31% to 12-13%. The finished product is thus hard and able to retain its shape and be stored without spoiling. Finally the pasta is packaged.

The scope of this work was to simulate the entire pasta production process, in particular we:

- studied the rheological aspects of the ingredients to verify the dough’s dependence on various parameters such as temperature, wheat milling and water

- simulated the entire mixing/extruding process to obtain the best quality and appearance of the pasta

- ensured that the flow rate of the dough through the extruder and the die remains uniform throughout the process. Variances in the flow rate will cause pasta to be extruded at different rates and produce pasta that is non-uniform in size resulting in increased costs to the process since that pasta must either be reprocessed or discarded

- reproduced the working pressure of the extruder which allowed us to perform a structural FEM analysis in order to verify stresses and deformations on the extruder and die

- virtually optimized the extruder and die shape to limit the recirculation of the dough. “Dead” zones in the flow cause local solidification of the dough with the consequence of higher maintenance costs and a low quality finished product

- simulated the drying cycle to control the time, temperature, moisture content, and the final hardness and shape of the pasta. In this phase it is important to ensure that the pasta pieces do not stick together and to control the moisture gradients from the surface to the interior of the pasta. If the past dries to fast it will crack on the other hand if the drying is too slow it will spoil and form mold before it dries

All of the single phases in the process were studied, simulated and optimized within an optimization framework. A physical test was carried out at a pasta factory for each phase to validate the simulation model built. The resulting simulation model, which uses a combination of features from modeFRONTIER, ANSYS, Ls-Dyna, CFX and Magma, provides a simulation environment that can be customized to fit the specific needs of any pasta manufacturer.

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.