SOLIDWORKS Design for Performance with Patterns

Overview

When designing components for use in larger assemblies it becomes important to optimize the

part’s feature design to minimize its impact on the rebuild time of the assembly at large. In this

case a great deal of processor/rebuild time can be spent on pattern features if they are not

optimized.

Pattern Types

There are several variations of patterns but these groupings will be generalized and grouped

together on the basis of rebuild efficiency.

Feature and Face Patterns

Feature and Face Patterns will attempt to construct the patterned instances based on the

conditions of the seed. If the seed is a cut produced with an end condition “Up to Surface” then

the patterned cuts will all seek to produce the same end condition based on the same surface as

the seed. In this way the patterned instances adjust their geometry to accommodate geometric

changes in the surface based on their locality. In this way they are more adaptible to changing

geometric situations but can be processor intense for rebuilds.

“Geometry” Feature, “Geometry” Face, and Body Patterns

Feature and Face Patterns set as a “Geometry pattern” as well as Body Patterns will attempt to

construct the precise same geometry as for each patterned instance as it does for the seed. Each

patterned instance is not a new recalculation of the geometry but instead and exact copy of the

seed. This allows the pattern to be much less processor intense when rebuilding at the cost of

being a less flexible feature definition.

Sketch Patterns

Sketch Patterns tend to be theprocessor intense as they require solving the sketch relation sin

addtion to generateing the pattern. Then proceeding with producing the feature itself can lead to

long rebuild times.

Cosmetic Hole Patterns

Cosmetic Patterns are the simplest and least flexible pattern definition. They are moreso an

appearance applied to a face than an actual feature. They are meant to only give the visual effect

of a pattern and are limited to only certain hole shapes and not actual model geometry is

produced. These patterns are very efficient.

Example

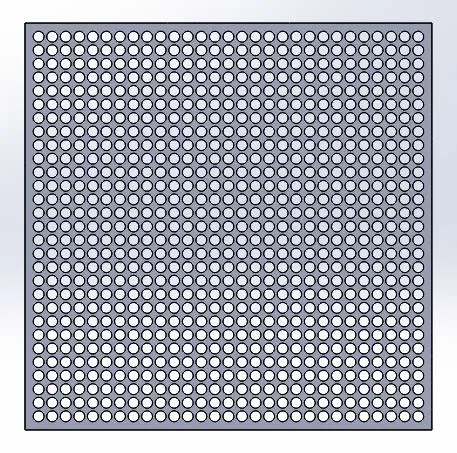

In this example a square plate is produced with 841 (29 by 29 linear pattern as shown below).

Rebuild times for each pattern are measured from the Feature Statistics dialog.

The rebuild times, as measured in seconds, for each setup are as follows:

| Sketch | Feature | |

| Feature and Face | 0.00 | 25.34 |

| "Geometry" Feature, Face, and Body | 0.00 | 1.34 |

| Sketch | 0.92 | 23.79 |

| Cosmetic Hole | - | 0.00 |

From the data it would be recommended to make use of “Geometry” type patterns and “Cosmetic

Hole” patterns before resorting to the remaining alternatives.

About Ryan Dark

Ryan has been in the GoEngineer technical support team since February 2008 where he most notably provides support for all FEA and CFD software offered by SolidWorks. His most recent accolade is the title of Elite Application Engineer awarded by SolidWorks Corp.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.