Stratasys J850 DIGITAL ANATOMY PRINTER

Ultra-Realistic Anatomical Simulation 3D Printing

Now Serving US & Canada

Now Serving US & Canada

REALISTIC ANATOMY

The relevance of 3D printing to the medical industry is fundamentally changing with the arrival of the Stratasys J850 Digital Anatomy Printer. Stratasys’ mission for the J850 DAP is to replicate the biomechanical properties of cardiac, vasculature, and bone in addition to general anatomies such as tumors, fibrotic tissue, soft or elastic organs, and more. With a shift away from printing “parts” to instead printing “anatomies,” the J850 DAP offers something medical professionals worldwide have dreamed of: on-demand, ultra-realistic anatomical simulation models.

“

These models give us the best opportunity to re-create human physiologic conditions on a structural basis to simulate clinical situations and study new devices to establish their effectiveness before introducing them into patients.

”

- Adnan Siddiqui, MD, PhD – Chief Medical Officer

![]()

What Can the J850 Digital Anatomy Printer Do?

Test & Validate

Test & Validate

Product engineers can now easily and quickly develop, test, and validate new medical devices.

Training

Training

Clinical educators can train the next generation of healthcare providers.

Experiment

Validation engineers can source test subjects and conduct critical experiments.

![]()

Preparation

Surgeons can prepare, practice, and perfect their skills in any clinical condition.

* When compared to synthetic and biological models (e.g., cadavers and animals)

Because the J850 Digital Anatomy 3D Printer allows you to produce anatomies that feel and behave like the real thing, it reduces the necessity for the use of synthetic models, animals, and cadaver labs, allowing you to test and train anywhere. That means a reduction in training and procurement costs. It also means improved ethical practice, because it eliminates the need to test surgical procedures and devices on animal subjects.

Features

COMPLEXITY

Bone and tissue are exceptionally intricate in their makeup – their multi-material, variable density, regional internal structures heavily influence their mechanical properties. An ultra-realistic model will need to replicate the interior structures of the anatomy – treat femurs differently than skulls – and the J850 DAP does that.

On-DEMAND MODELS

Print the exact organ, of the right age and/or pathology, that you need for your research or experiment. Do it today, in the comfort of your lab, and be ready to move forward tomorrow. Enjoy unparalleled productivity and efficiency in your engineering and educational endeavors.

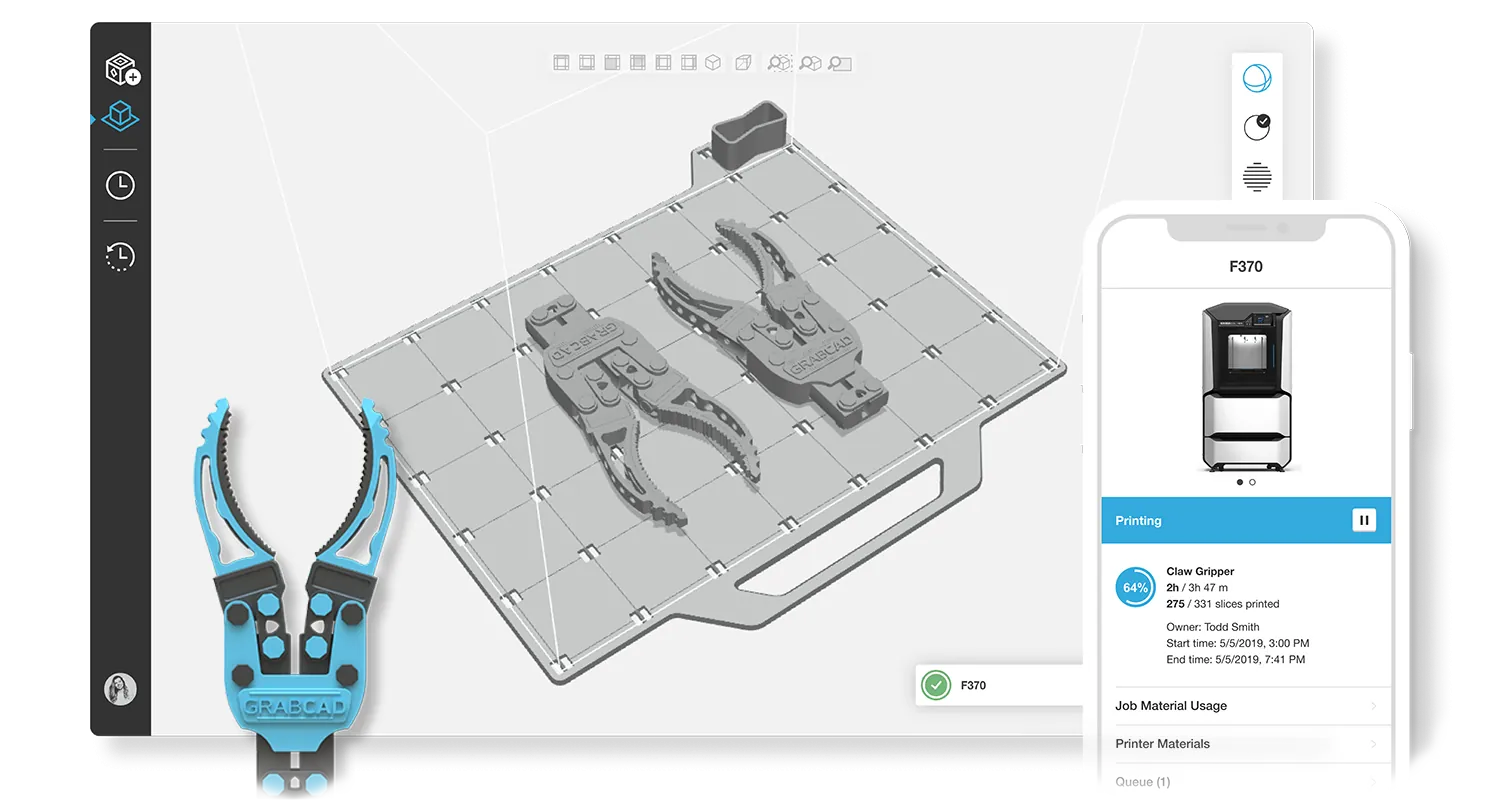

Voxel Printing

The hardware is important – the ability to print six materials simultaneously (and water-soluble support) is a pre-requisite to creating hyper-realistic anatomical models. But an easy-to-use software, with drop-down menus for 100+ anatomical presets, is what empowers the everyday user to take advantage of the J850 DAP. Complex internal structures and regions are built at the voxel level automatically by GrabCAD Print. Only a few clicks are required to print calcified blood vessels or cardiac blood clots – no medical experience necessary.

Matrix Materials

New materials, developed specifically to match anatomical requirements, help make this solution reality. TissueMatrix, BoneMatrix, RadioMatrix, and GelMatrix are combined during the print process in the same way a desktop printer combines CYMK ink to achieve hundreds of thousands of colors (which, by the way, the J850 can also do!). Think of it this way: instead of loading CMYK inks you are loading flesh, fat. bone, connective tissue, skin and the printer is outputting ultra-realistic anatomical models.

MATERIALS

The Stratasys J850 Digitial Anatomy Printer features four specialized resins as well as the full PolyJet range.

GelMatrix™ resin

Gel-like support material for easy removal from blood vessels. Inner diameter as small as 1 mm and wall thickness as low as 1.5 mm.

TissueMatrix™ resin

The softest translucent material commercially available. Ideal for replicating the look and feel of heart tissue.

BoneMatrix™ resin

A strong, yet flexible, material with memory to maintain its shape.

Radiomatrix™ resin

Print medical models with radio-realistic features under X-ray and CT.

STRATASYS J850 DIGITAL ANATOMY POLYJET MATERIALS

Vero

Realistic & vibrant colors

– Multi-purpose, multi-color family of materials | CMYKBWV

– Good stiffness and strength

– Blend together or with other materials to change properties

• Hardness | flexibility | translucency | heat resistance

– Wash-away or soluble support available

Potential applications:

– Visually realistic prototypes

– Fit, form, and function prototypes

– Surgical models

– Jigs, fixtures, & tooling

VeroClear / VeroUltraClear

Simulated acrylic

– Transparent material similar to Polymethyl methacrylate (PMMA)

– Used to Simulate Transparent Products

– Blend together or with other materials to change properties

• Hardness | Opacities | Hues

Potential applications:

– Simulated clear and transparent parts

– Fit and form prototypes

– See-through parts & visual aids

VEROFLEX

A versatile vero

– Vero material with added flexibility and toughness

– Full part realism

– Available in multiple flavors

• CMYKWB | Clear | Vivid CMY

Potential applications:

– Eyewear prototypes

– Fit, form, function prototypes

– Aesthetic models

TANGO

Simulated Rubber

– Flexible, rubber-like material

– Test and verify visual, tactile, and functional applications

– Offers shock absorption & vibration dampening

– Blend with other materials to change properties

• Hardness | Elongation | Tear resistance

Potential applications:

– Soft touch coatings

– Non-slip surfaces

– Grips | Pulls | handles | buttons

– Footwear prototypes

Agilus30

Simulated Rubber

– Flexible, rubber-like material

– Ideal for advanced design verification

– Superior durability, tear resistance, and shape memory

– Improved fatigue resistance for repeated bending & flexing

– Blend with other materials to change properties

• Hardness | Elongation | Tear resistance

Potential applications:

– Soft touch coatings

– Living hinges

– Jigs & fixtures

– Wearables

Digital ABS Plus

Simulated ABS

– Most mechanically robust Polyjet material

– Combines temperature resistance with toughness

– Good impact strength

– 2 material blend

Potential applications:

– Design verification

– Functional testing

– Jigs & fixtures

– Manufacturing tooling

Durus

Simulated Polypropylene

– Developed to simulate common consumer thermoplastic

– Improved resilience and elongation while remaining rigid

– Good for parts with delicate features and small cavities

• Hardness | Flexibility | Translucency | Heat resistance

– Wash-away or soluble support available

Potential applications:

– Fit, form, function prototypes

– Snap-fit features

– Living hinges

Rigur

Simulated Polypropylene

– Advanced simulated polypropylene material

– Improved durability, toughness, and fatigue resistance

– Excellent option for blending with other materials

– Bright white color ideal for some aesthetic applications

Potential applications:

– Fit, form, and function prototypes

– Snap-fit features

– Living hinges

– Reusable containers & packaging

ToughONE

Strong PolyJet Material

– High level strength for functional prototyping

– Small batch runs for alpha and beta testing

– TPO-free

– High impact resistant and shock absorption

Potential applications:

– Packaging

– Consumer goods & electronics

– Automotive

High Temperature

For when it’s HOT

– Rigid, opaque material with elevated heat resistance

– Ideal for static parts or thermal testing parts

– Good strength and stiffness

– Pair with PolyJet rubber-like materials for added function

Potential applications:

– Fit, form, and function prototypes

– Hot air flow

– Hot water flow

– Parts near hot lights or other heat source

Biocompatible

Medically Approved

– Transparent, biocompatible materials approved for bodily contact

– Designed for medical and dental applications

– Approved for limited skin contact and mucosal contact

• < 30 days | up to 24 hours

– Evaluated and deemed acceptable for other biological risks

• Cytotoxicity | Irritation | Delayed-Type Hypersensitivity | Genotoxicity | Chemical characterization | USP Plastic Class VI

– Biocompatible family contains 3 materials

• Med610 | Med625FLX | VeroGlaze Med620

Dental Materials

Surgical Guides / Implant Models / Gingival Masks

Stratasys dental materials are ideal for accurate detail visualization and precise, functional models. With PolyJet materials, dental labs can readily access flexible materials for multiple applications simultaneously,

Material Options:

– Biocompatible MED625FLX

– Biocompatible MED610

– Biocompatible VeroGlaze MED620

– VeroDent MED670

– VeroDentPlus MED690

“

3D printing helped me take somebody from being inoperable to operable, and we saved her life.

”

- Raymond P. Burke, M.D. - Cardiovascular Surgery

J850 Digital Anatomy Specifications

Model Materials

- Vero™ family of opaque materials including neutral shades and vibrant VeroVivid™ colors

- Agilus30, TangoPlus™ and TangoBlackPlus™ flexible materials

- VeroClear, VeroUltra™ Clear transparent materials

- TissueMatrix, BoneMatrix, GelMatrix, RadioMatrix

- Biocompatible Clear

Digital Model Materials

Unlimited number of composite materials including:

- Over 500,000 colors

- Digital ABS Plus and Digital ABS2 Plus™ in ivory and green

- Rubber-like materials in a variety of Shore A values

- Ultra-soft rubber-like material with a Shore 00 value

- Translucent color tints

- User-developed digital materials with GrabCAD Voxel Print™

Support Materials

SUP705™ (WaterJet removable)

SUP706B™ (soluble)

GelMatrix (waterjet removable)

Build Size

Stratasys J850 : 490 x 390 x 200 mm (19.3 x 15.35 x 7.9 in.)

Layer Thickness

Workstation Compatibility

Windows 7 and 8.1

Network Connectivity

System Size and Weight

System: 1400 x 1260 x 1100 mm (55.1 x 49.6 x 43.4 in.); 430 kg (948 lbs.)

Material Cabinet: 670 x 1170 x 640 mm (26.4 x 46.1 x 25.2 in.); 152 kg (335 lbs.)

Operating Conditions

Power Requirements

220–240 VAC, 50–60 Hz, 7 A, 1 phase

Regulatory Compliance

Software

GrabCAD Print Digital Anatomy software.

Optional add-on GrabCAD Voxel Print and/or Digital Anatomy Creator software

Build Modes

High Quality (HQ) – 7 different materials / 14μm layers

High Mix (HM) – 7 materials / 27μm

High Speed (HS) – 3 materials / 27μm, x2 speed

Super High Speed (SHS)- 1 material / 54 μm, x4 speed

Accuracy

Typical deviation from STL dimensions, for models printed with rigid materials, based on size:

under 100 mm: ±100μ; above100 mm: ±200μ or ± 0.06% of part length, whichever is greater.

Please refer to material-specific spec sheets for accuracy estimates.

Software

GrabCAD Print

GrabCAD Print makes 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

Frequently Asked Questions

The mission to recreate anatomy could be viewed as daunting – there are countless combinations of variables. But the implications of such an ability are an enormous good for the medical industry and Stratasys is committed to accomplishing that goal. Extensive R&D and industry partnerships will bring new materials, new anatomies, and new pathologies to the J850 DAP platform for years to come.

Yes! You can visit stratasys.com/recycle and fill out a free shipping label to return empty canisters back to Stratasys. They require you have at least four empty canisters to ship back.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services