Stratasys J850 TechStyle

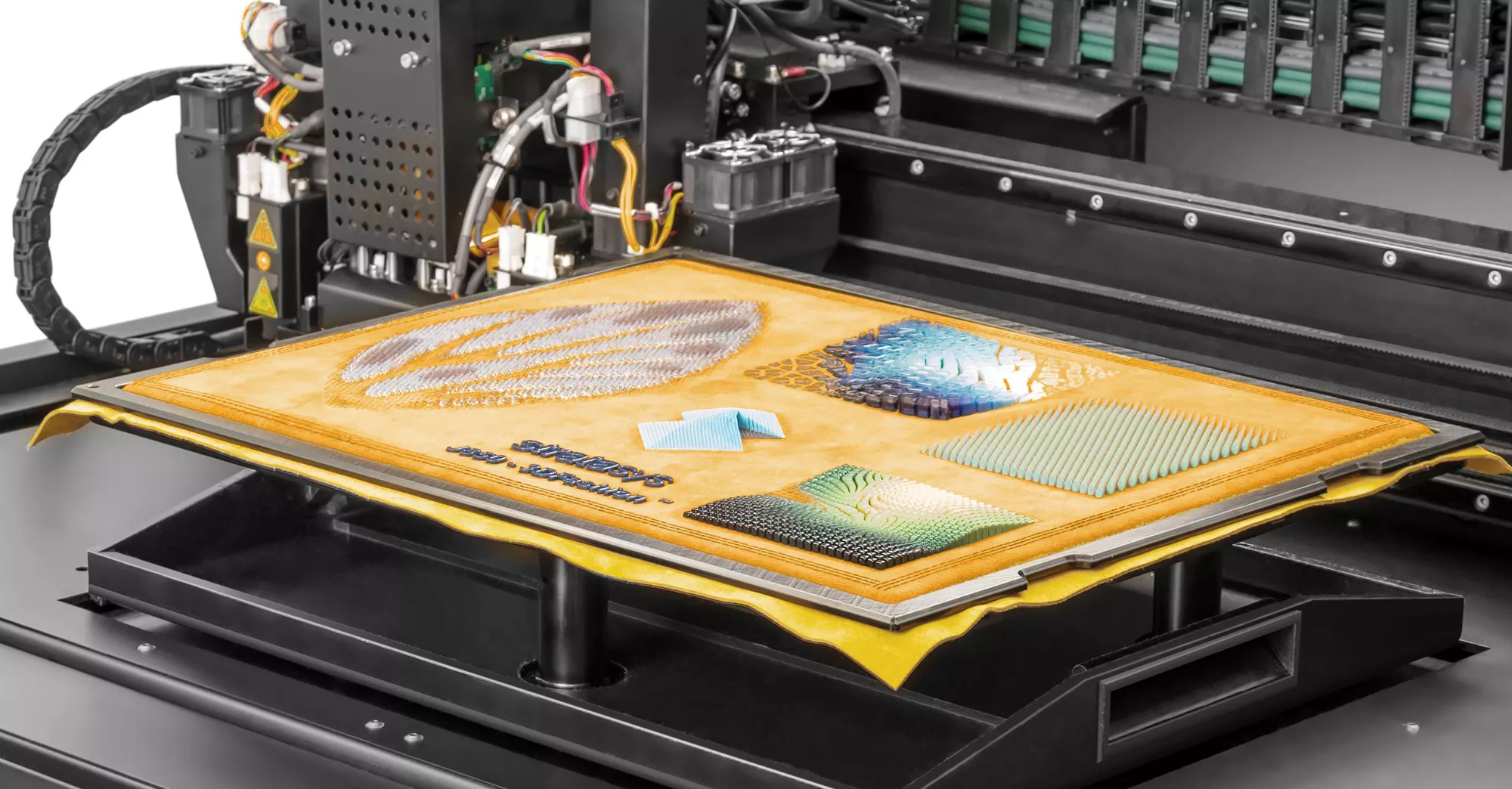

3D Print Full-color and Multi-material Directly Onto Fabrics and Textiles

Now Serving US & Canada

Now Serving US & Canada

Fashion Designing Re-imagined

The power of 3D Printing is ready to take on the fashion industry. The Stratasys J850™ TechStyle 3D printer has made the impossible — possible. With the ability to create optical illusions of color and textures, fashion designers can now 3D print their creations directly on various fabrics and textiles providing the ultimate level of style.

“I gravitate toward new technologies that afford me an opportunity to create something original. With Stratasys 3D fashion printing technology, the possibilities are endless. Honestly, it provides a chance to experiment, and I feel like I have only scratched the surface of what is possible.”

- Karim Rashid – Fashion Designer

What Can the J850 TechStyle 3D Printer Do?

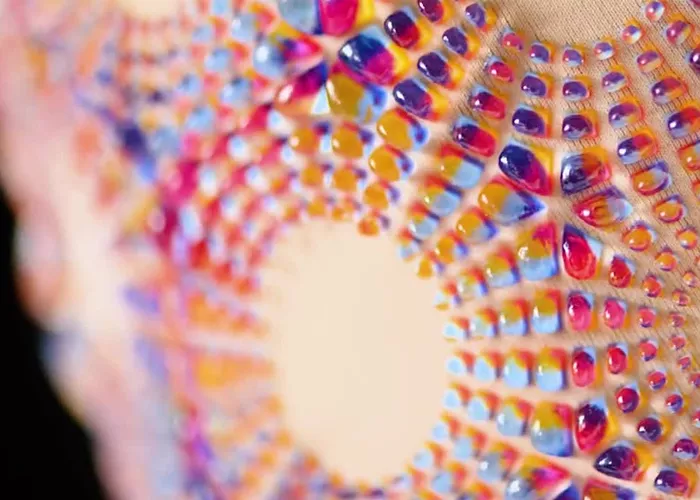

Limitless Color

This cutting-edge technology provides access to over 600K colors and Pantone Validated™ palettes, available in both matte and glossy finishes.

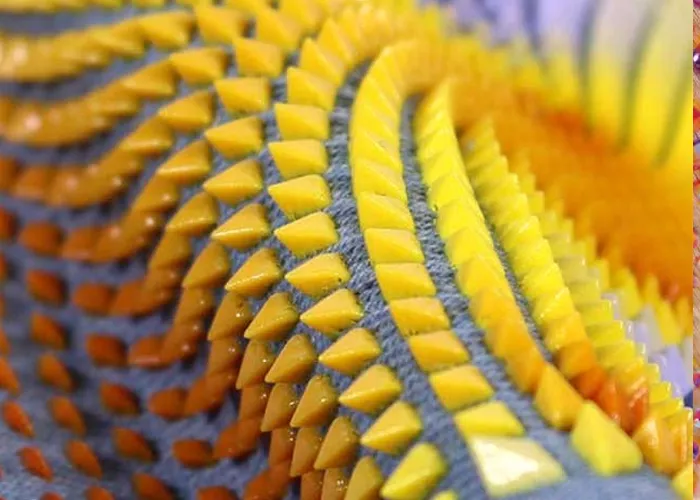

Texture

Achieve varied transparency and textures by printing up to 7 different materials directly onto fabric simultaneously.

Uniqueness

The ability to combine different materials, colors, and textures in your designs gives you the freedom to push boundaries and create designs that are truly distinctive.

Creativity

Whether you're a designer looking to make a bold statement or a fashion brand seeking to set yourself apart, this 3D printer offers unparalleled versatility and opens up a world of possibilities for creative expression in the realm of textiles.

Features

Large Build Volume

The J850 TechStyle 3D Printer offers a relatively large build volume, allowing for the creation of larger and more complex objects in a single print job. This is beneficial for industries that require the production of life-size or scaled-up prototypes, such as automotive, aerospace, and architecture.

Multi-Material Printing

The J850 TechStyle 3D Printer can print objects using a wide range of colors and materials simultaneously. It has the ability to create vibrant, full-color models with intricate details and smooth gradients. This makes it suitable for applications where aesthetics and realism are important, such as architectural models, product prototypes, and medical visualizations.

High Precision and Detail

The J850 TechStyle is capable of producing highly detailed and precise prints, thanks to its fine printing resolution. It can achieve layer heights as low as 14 microns, resulting in smooth surfaces and intricate features. This level of precision makes the J850 TechStyle suitable for applications that demand intricate designs, like jewelry, miniatures, and artistic sculptures.

J850 TECHSTYLE MATERIALS

Vero

Realistic & vibrant colors

– Multi-purpose, multi-color family of materials | CMYKBWV

– Good stiffness and strength

– Blend together or with other materials to change properties

• Hardness | flexibility | translucency | heat resistance

– Wash-away or soluble support available

– VeroEco Flex versions with RSL (Restricted Substances List for Finished Products) compliant

Potential applications:

– Visually realistic prototypes

– Fit, form, and function prototypes

VeroUltra

VeroUltra White, VeroUltra Black, & Veroultraclear

–

Impressive contrast and color separation

–

Smooth color transition

–

Can be combined with various materials

–

Superior capacity application

Potential applications:

–

Toy & figurine production

–

Consumer electronics

– Packaging

– Fashion and Art

– Consumer goods

Agilus30

Simulated Rubber

– Flexible, rubber-like material

– Ideal for advanced design verification

– Superior durability, tear resistance, and shape memory

– Improved fatigue resistance for repeated bending & flexing

– Blend with other materials to change properties

• Hardness | Elongation | Tear resistance

Potential applications:

– Soft touch coatings

– Living hinges

– Jigs & fixtures

– Wearables

VEROVIVID

VEROVIVID

–

Full-color capabilities

–

500,000+ color simulations

–

Create lifelike medical models & realistic packaging

Potential applications:

–

Prototyping

– Simulating Pantone colors

– Medical applications

– Fashion and art

– Simulating finishes and textures

“

3D printing helped me take somebody from being inoperable to operable, and we saved her life.

”

- Raymond P. Burke, M.D. - Cardiovascular Surgery

J850 TechStyle Specifications

STANDARD Materials

-

VeroUltra™ & VeroVivid™ family of opaque and transparent materials + neutral

shades and vibrant colors. - Agilus30™ family of flexible materials: Clear, Black, White, Cyan, Magenta and Yellow.

Digital Model Materials

Unlimited number of composite materials including:

- Over 600K available colors in both matte and glossy finishes

- Translucent color tints

- Flexible tactile materials in a variety of textures and colors

Support Materials

SUP705™ (WaterJet removable)

SUP706B™ (Waterjet removable)

Printed Textile Testing*

ISO standards

100%

Cotton

100%

Polyester

50/50%

Cotton Polyester

Linen

ISO 105-C06:2010 @40c (1-5)

5

5

5

5

ISO 105-C06:2010 @60c (1-5)

5

5

5

5

ISO 105-B02:2013 (1-8)

7-8

7-8

7-8

7-8

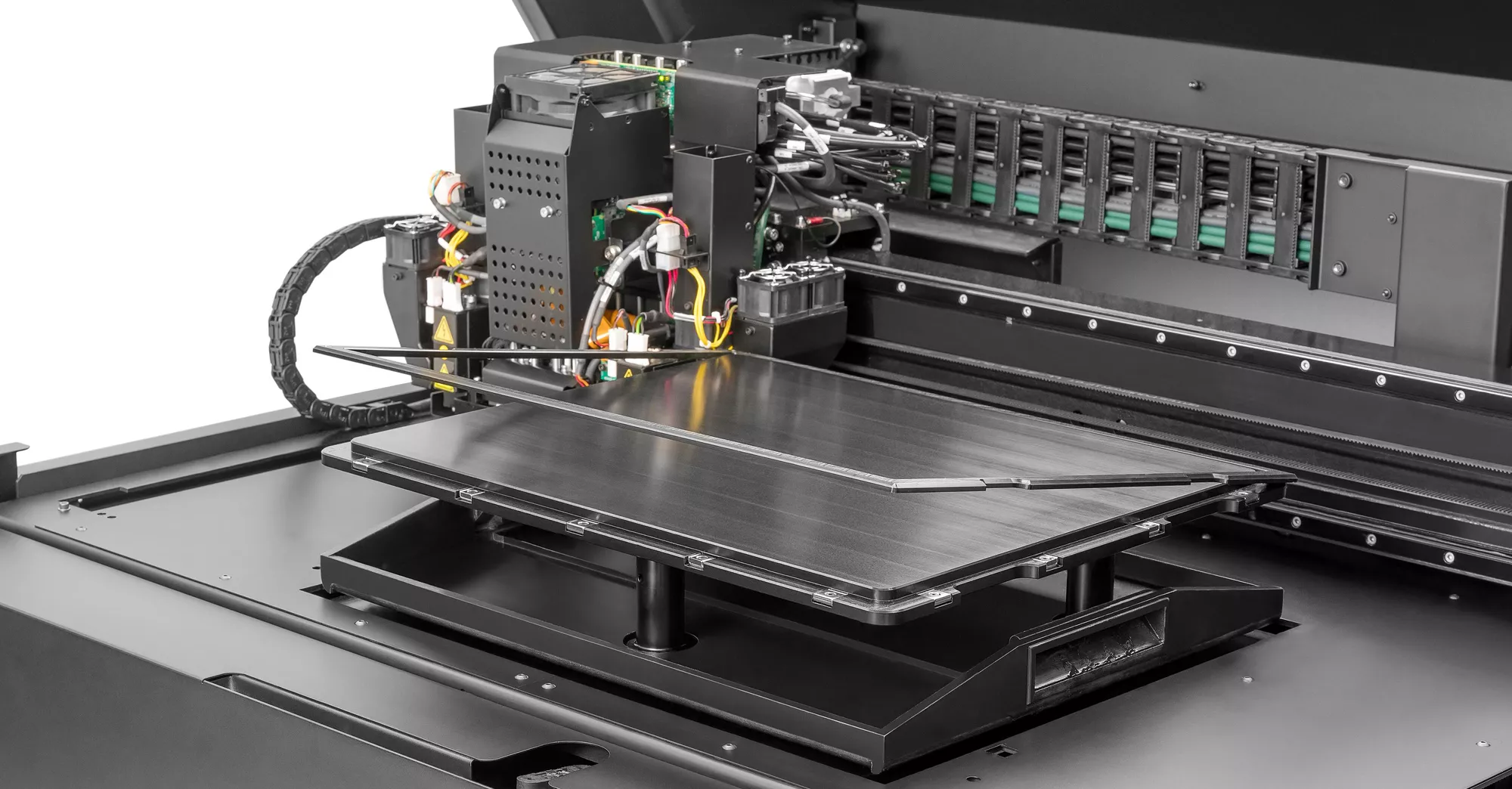

Build Size

Fabric Size Handling:

min 560 x 460mm; max 2 x 2m

Fabric Thickness:

0.1-3.0mm

Interchangeable Tray for smooth production runs

Effective Printing Area

460 x 360 x 50 mm (18.1 x 14.2 x 1.9 in) on a stretch of fabric up to 2m2

Layer Thickness

Horizontal build layers down to 27-micron (0.001 in.)

Workstation Compatibility

Windows 10

Network Connectivity

LAN - TCP/IP

Industry 4.0 Compliance

System Size and Weight

J850 TechStyle System:

1400 x 1260 x 1100 mm (55.1 x 49.6 x 43.4 in.); 430 kg (948 lbs.)

J850 TechStyle Material Cabinet:

1119 x 656 x 637 mm (44 x 25.8 x 25.1 in.); 153 kg (337 lbs.)

Operating Conditions

Temperature 18 – 25 °C (64 – 77 °F); relative humidity 30-70% (non-condensing)

Power Requirements

100–120 VAC, 50–60 Hz, 13.5 A, 1 phase; 220–240 VAC, 50–60 Hz, 7 A, 1 phase

Regulatory Compliance

CE, FCC, EAC, RCM, R-NZ1

Software

GrabCAD Print - GrabCAD Printer Connectivity SDK

Build Modes

High Mix:

up to 7 base resins, 27-micron (0.001 in.) resolution

High Speed:

up to 3 base resins, 27-micron (0.001 in.) resolution

Accuracy

J850 TechStyle System:

Typical deviation from STL dimensions, for models printed

with rigid materials, based on size: under 100 mm – ±100μ; above 100 mm – ±200μ

or ± 0.06% of part length, whichever is greater.

Software:

Deviation from STL dimensions, for 1 Sigma (67%) of models printed with

rigid materials, based on size: under 100 mm – ±150μ; above 100 mm – ±0.15% of

part length.

Deviation from STL dimensions, for 2 Sigma (95%) of models printed with rigid

materials, based on size: under 100 mm – ±180μ; above 100 mm – ±0.2% of part

length.

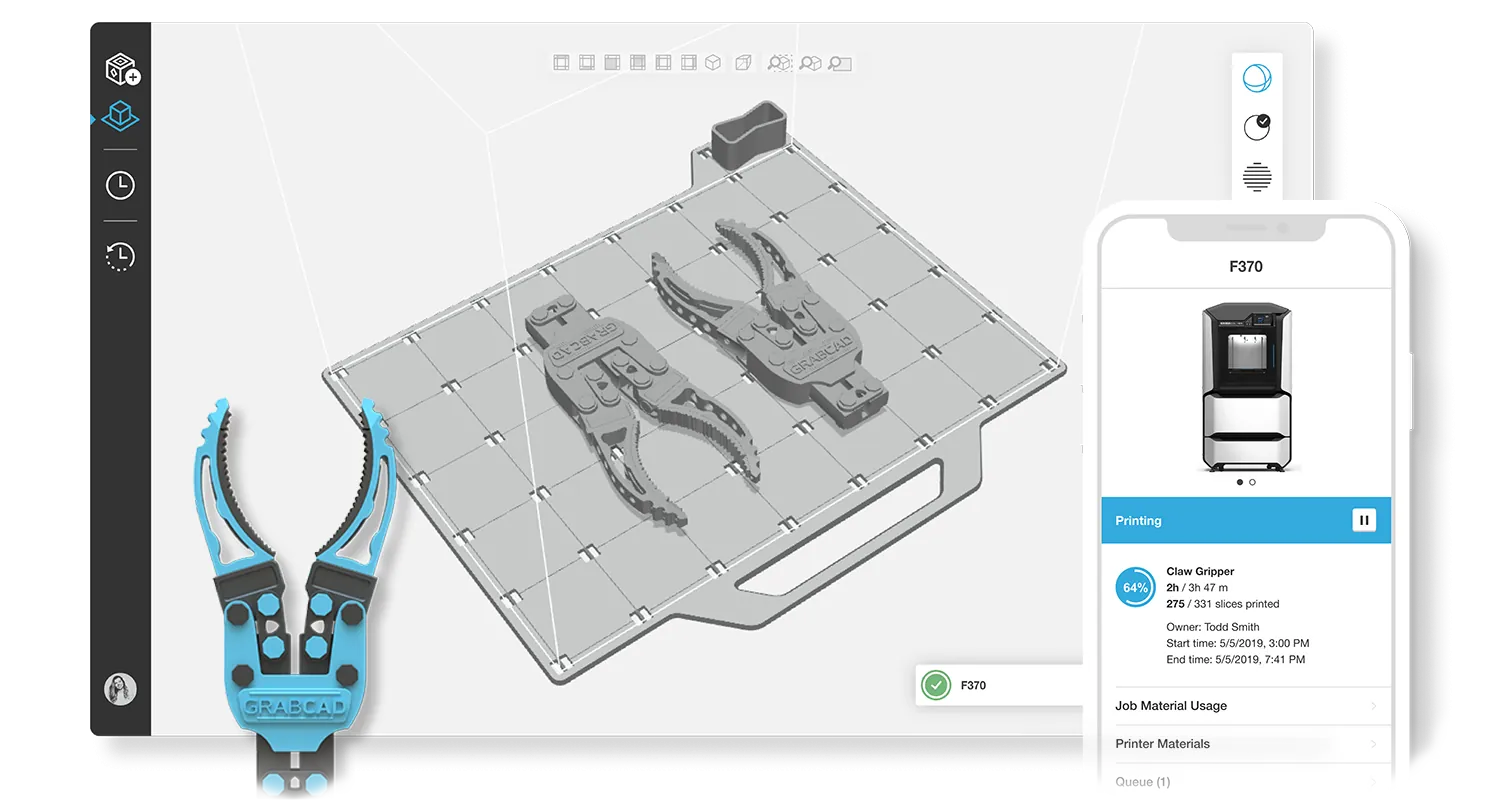

Software

GrabCAD Print

GrabCAD Print makes 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

Frequently Asked Questions

Yes, the Stratasys J850 TechStyle can print on leather.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services