UltiMaker Factor 4

Large build volume, dual extrusion, and precise 3D printing capabilities

Now Serving US & Canada

Now Serving US & Canada

Industrial-grade 3D Printing Built for the Factory Floor

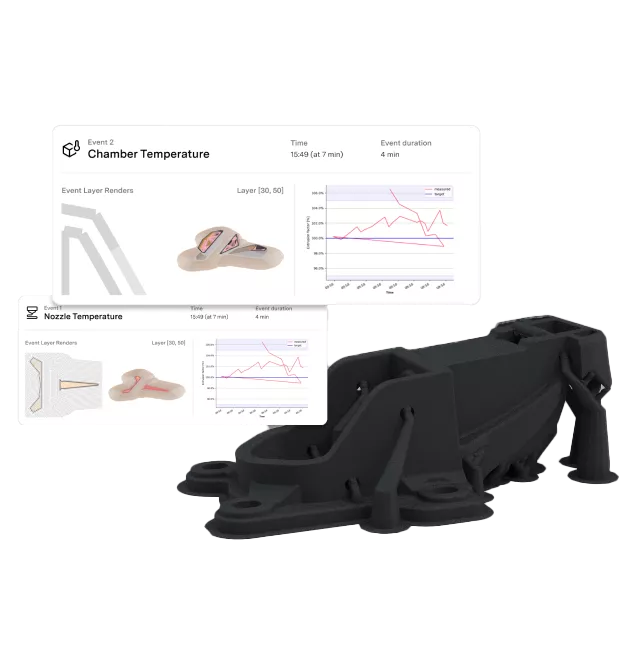

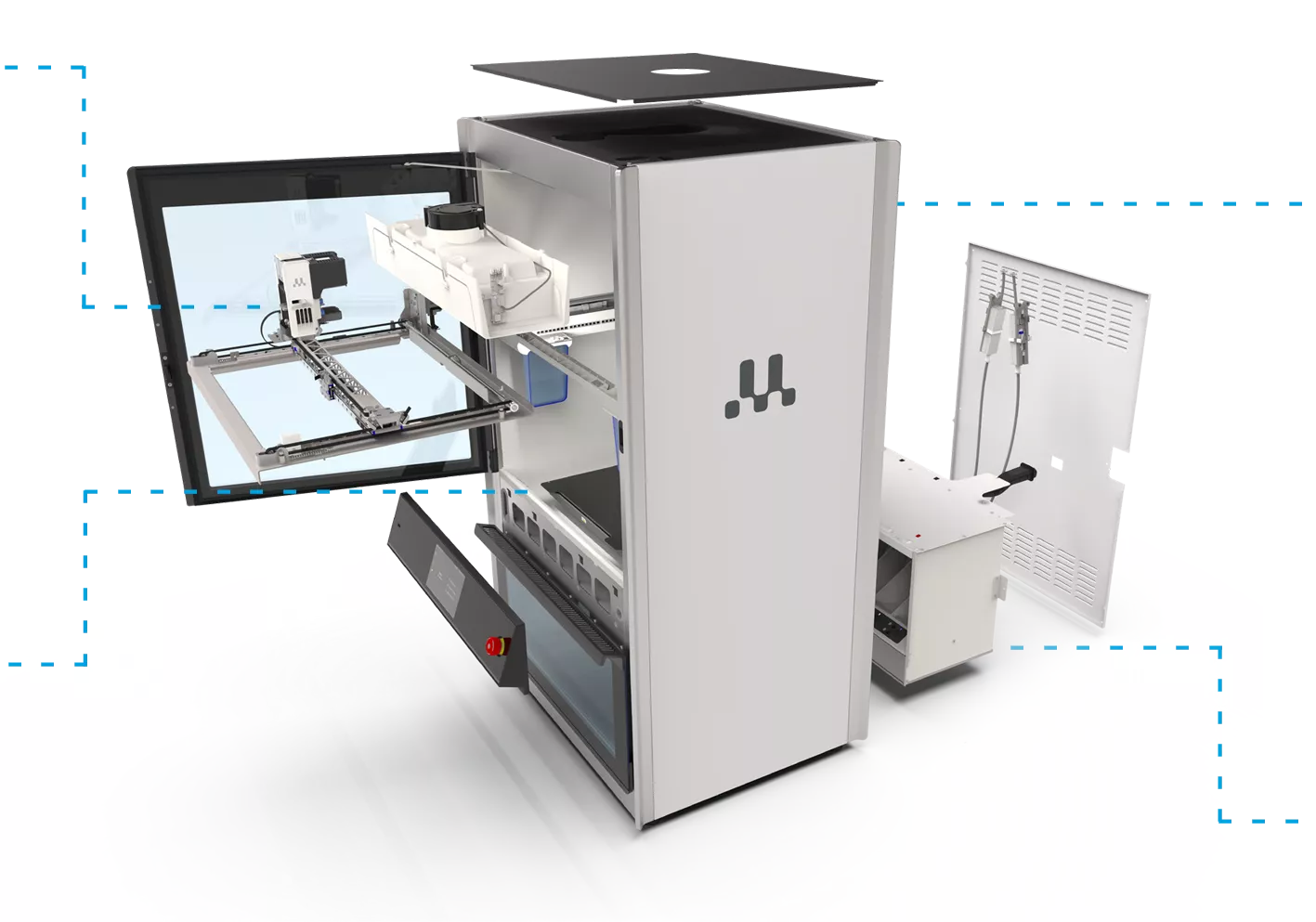

The UltiMaker Factor 4 is an advanced industrial-grade 3D printer designed to optimize production processes and keep operations running smoothly. With its support for engineering materials, dual extrusion, and onboard print process reporting, this 3D printer is equipped with the latest innovations that ensure unrivaled predictability, minimal variance, and the highest level of accuracy.

Dual extrusion direct drive print head and H-bridge gantry enable rapid dual material printing

Actively controlled build volume temperature

Automated material handling system with low relative humidity storage

Impressive build volume of 330 x 240 mm in XY

Dual print head

Dual extrusion direct drive print heads and H-bridge gantry enable rapid dual material printing.

Large Build Volume

Achieve high-quality printing at an accelerated speed.

controlled build TEMP

Actively controlled temperatures across the build plate ensure optimal printing conditions.

Automated Material Handling

Efficiently maximizes capacity without compromising on size.

“With the Factor 4 in combination with the Lehvoss materials we can really achieve applications that require higher specs in terms of dimm accuracy and reliability.”

– Thiago Medeiros Araujo

Market Development Manager ![]()

Features

built for the Factory Floor

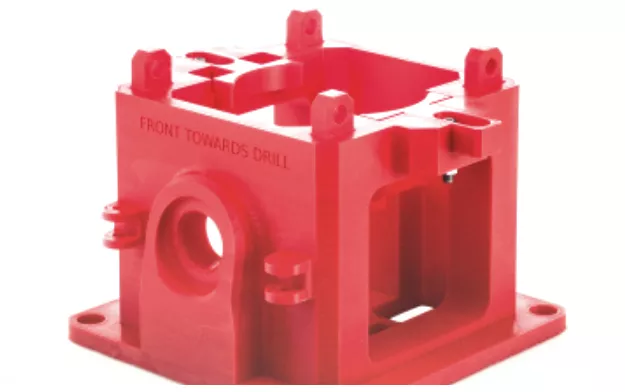

Factor 4 sets a new standard for 3D printing in manufacturing settings. Its build chamber is triple-insulated and equipped with direct dual extrusion. The automated material handling system ensures high filament quality, while the temperature-controlled design guarantees consistent production output, even on complex and challenging designs.

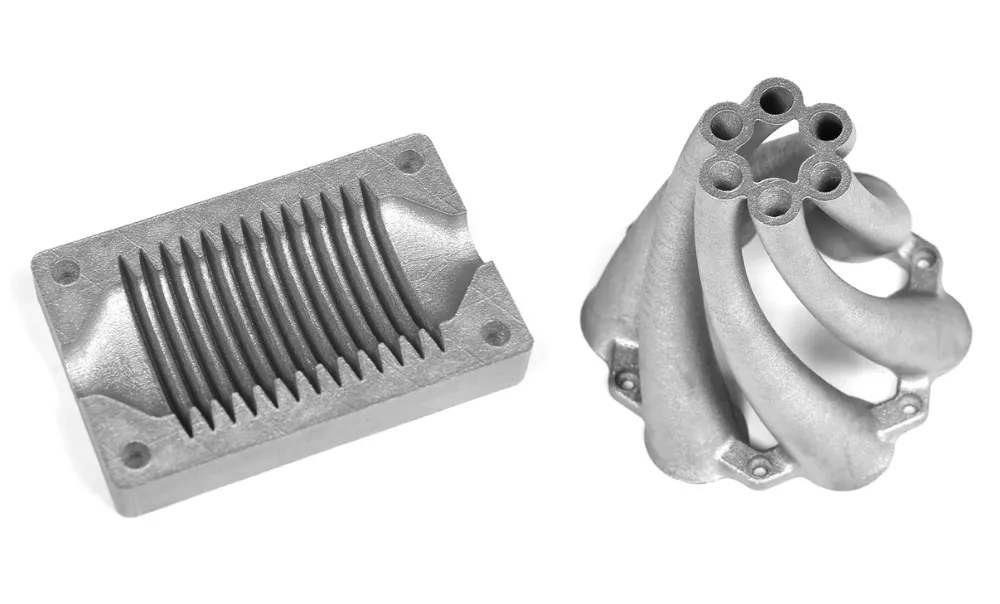

Reliable, Repeatable Results

The Factor 4 is equipped with a flexible build plate that measures 330 x 240 mm, providing users with the confidence to print objects with ease, and the PEI coating on the plate ensures that parts can be removed quickly.The dimensional accuracy of the UltiMaker has been verified to be within ±0.2 mm or ±0.2% nominal length across the entire printer build volume, using materials such as PPS CF, PET CF, Tough PLA, and PETG. With fast dual printing capabilities, users can leverage the full power of additive manufacturing to produce complex geometries and multimaterial parts.

Hassle-free Material Handling

The automated material handling system seamlessly manages your spools, eliminating the need for manual intervention. The internal chamber is maintained at less than 10% RH in office conditions, which ensures that you can store up to 6 kilograms of filament in perfect condition for uninterrupted print jobs.

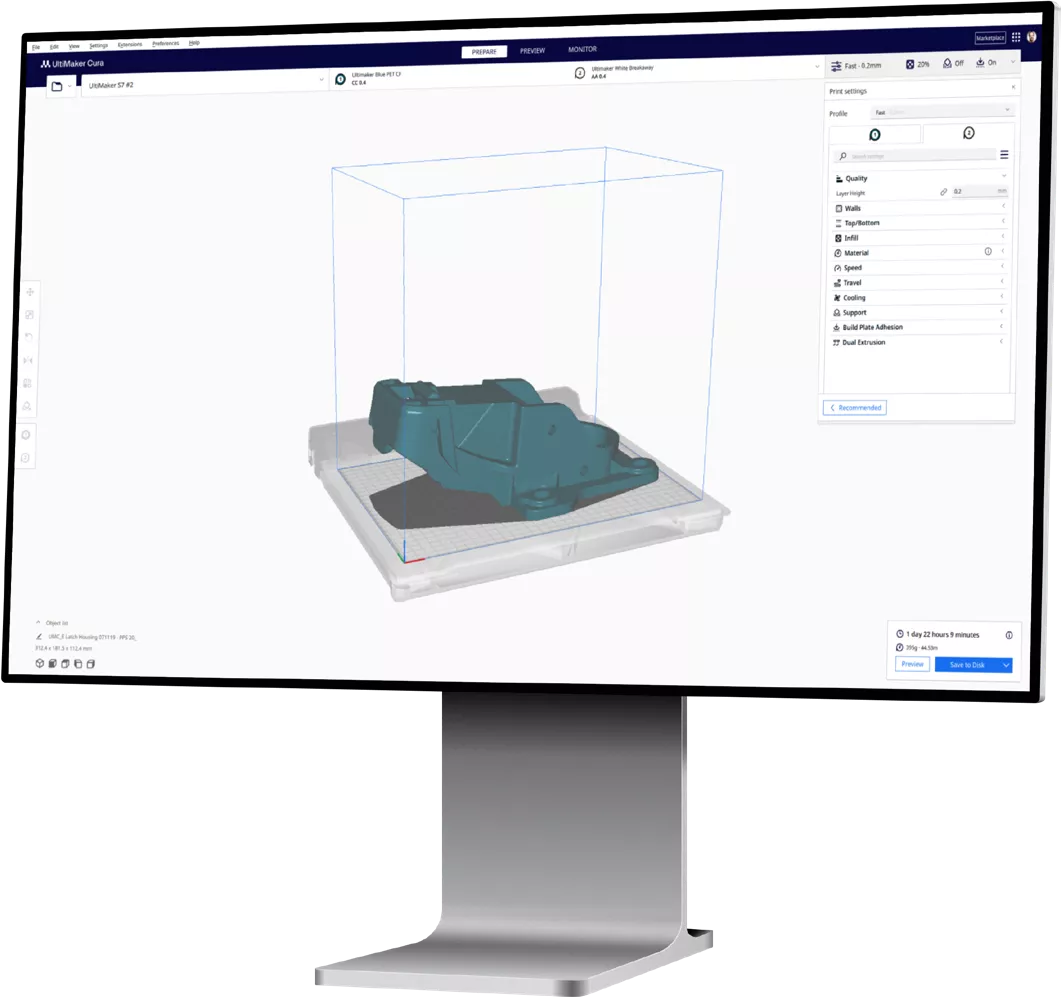

Seamless Software Integration

UltiMaker Cura and Digital Factory work in conjunction with Factor 4 and UltiMaker materials to provide a seamless and secure workflow for 3D printing. This software leads the AM industry, thanks to its powerful slicing engine. It can quickly slice various file types, including native CAD files, using pre-tuned application intent profiles. Coordinating your printing schedule is a breeze with shared workspaces, assigned roles, and file management using the digital library. Additionally, each Factor 4 printer comes with a live HD camera feed, progress and status updates, making it easy to handle multiple prints on multiple printers without any downtime.

Feature 5

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Factor 4 Materials

|

|

PPS CF

|

|

Hardness: 80 Shore D |

|

|

Print Core: HT |

|

|

Thermal: 230° C |

|

|

Impact Strength: 4.8 kj/m² |

ABS

|

|

Hardness: 76 Shore D |

|

|

Print Core: 1AA |

|

|

Thermal: 87° C |

|

|

Impact Strength: 14 kj/m² |

Nylon

|

|

Hardness: 81 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 89° C |

|

|

Impact Strength: 14 kj/m² |

PC

|

|

Hardness: 81 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 111° C |

|

|

Impact Strength: 12 kj/m² |

Tough PLA

|

|

Hardness: 80 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 58° C |

|

|

Impact Strength: 9 kj/m² |

PLA

|

|

Hardness: 84 |

|

|

Print Core: AA |

|

|

Thermal: 59° C |

|

|

Impact Strength: 4 kj/m² |

|

|

PETG

|

|

Hardness: 76 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 76° C |

|

|

Impact Strength: 8 kj/m² |

|

|

CPE

|

|

Hardness: 76 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 77° C |

|

|

Impact Strength: 6 kj/m² |

|

|

CPE+

|

|

Hardness: 77 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 100° C |

|

|

Impact Strength: 37 kj/m² |

|

|

TPU 95A

|

|

Hardness: 48 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 116° C |

|

|

Impact Strength: 24 kj/m² |

|

|

PP

|

|

Hardness: 42 Shore D |

|

|

Print Core: AA |

|

|

Thermal: 99° C |

|

|

Impact Strength: 49 kj/m² |

Factor 4 Specifications

Printing properties

- Technology: Fused deposition modeling (FDM)

- Extrusion system: Dual-extrusion, direct drive print head with unique auto-nozzle

lifting system and swappable print cores - Build volume: Single material printing: 330 x 240 x 300 mm (13 x 9.4 x 11.8 in)

Dual material printing: 330 x 240 x 300 mm (13 x 9.4 x 11.8 in) - Filament diameter: 2.85 mm

- Print profiles availability :14+ UltiMaker materials

200+ UltiMaker Marketplace materials - Dimensional accuracy: ± 0.2 mm ± 0.2 % feature nominal length.

Hardware properties

- XYZ resolution: 6.25, 7.8, 2.5 micron

- Homing sensor: Optical

- Build plate: PEI-coated flexible build plate

- Build plate temperature: Up to 120 °C

- Build volume temperature:

- Actively controlled up to 70 °Cwith nozzle plane temperature uniformity within:

- ± 3 °C for temperatures < 50 °C

- ± 5 °C for temperatures < 70 °C

- Extrusion flow: Closed loop flow compensation

- Max. extrusion temperature:

- 280 °C: Print core AA, BB, DD

- 300 °C: Print core CC

- 340 °C: Print core HT

- Compatible print cores:

- Print core AA (0.25 mm, 0.4 mm, 0.8 mm)

- Print core BB (0.4 mm, 0.8 mm)

- Print core CC (0.4 mm, 0.6 mm)

- Print core DD (0.4 mm) – available in selected regions

- Print core HT (0.6 mm)

- Closed loop fans: Air filtering fan, air recirculation fans, print cooling fans, print core cooling fan

- Material handling capacity: 6 bays with NFC recognition (max. 1 kg spool size)

- Material humidity control: Average relative humidity < 15 % in all operational conditions

- Filtration system: HEPA H13

- Emission rate (UFP & VOC): UltiMaker filaments below limits listed in UL-2904

- Monitoring HDR: (high dynamic range) 1920 x 1080 px HD camera

- Display: 7-inch touchscreen (resolution 1024 x 600 px)

- Connectivity:

- Wi-Fi 2.4 & 5 GHz: IEEE 802.11a/b/g/n/ac

- LAN: Gigabit Ethernet

- USB: 2.0

- System on module: NXP i.MX8 Mini Quad (4 x 1.8 GHz), ARM Cortex-A53, 2 GB LPDDR 4 16 GB eMMC

- Real time controller: i.MX RT1064, Arm Cortex-M7 600 MHz, 1 MB SRAM

- Power requirement: 100 – 240 V AC, 50 – 60 Hz max., 6A

Physical dimensions

- Dimensions: 695 x 605 x 1287 mm (27.5 x 24 x 51 in)

- Weight: 120 kg (265 lbs)

- Shipping dimensions: 760 x 800 x 1587 mm (30 x 31.5 x 62.5 in)

- Shipping weight :137 kg (309 lbs)

Ambient conditions

- Operating sound: < 50 dBA in operation

- Operating environment:

- Operating: Temperature: 18 °C – 30 ºC, humidity: 30 – 70% RH

- Storage: Temperature: 5 °C – 40 ºC, humidity: 20 – 90% RH

Software

- Print job preparation: UltiMaker Cura 5.7.1 or newer

- Print job management: UltiMaker Digital Factory

- File types supported:

- UltiMaker Cura: STL, OBJ, 3MF

- Printable formats: G, GCODE, UFP, STEP

- System requirement:

- Windows 7 (64-bit), Mac OS X 10.12, OpenGL 2.1\

- 4 GB RAM (8 GB recommended)

- Print process reporting: Supported

- Security: Active firewall and PIN code settings protection

Safety and compliance

- Warranty period: 12 months limited warranty

- Safety features: Red stop button immediately stops motion and heat sources, open door sensor pauses motion and extrusion

Software

UltiMaker Cura

Ensure a straightforward, secure, and dependable workflow from 3D model to finished print:

- UltiMaker Cura: Easy print preparation for manufacturing

- Onboard structural integrity validation.

- UltiMaker Digital Factory: Secure, efficient 3D printing management.

- Modularity at your service.

Additional 3D Printers

FDM

Design an idea and test it the same day. Industries can cut lead times and costs, products turn out better, and you get to market faster. FDM 3D PrintersMETAL

3D print functional metal parts and prototypes for industrial, commercial, and private applications. Metal 3D PrintersSAF

Selective Absorption Fusion™ SAF™ technology that delivers functional, production grade parts with optimum consistency. Production SAF 3D PrintersP3

Programmable PhotoPolymerization P3™ technology delivers industry-leading accuracy, consistency, and details. Production P3 3D PrintersADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services