CATIA V5 Accelerator Series

Automate tasks and streamline CATIA V5 workflows to boost productivity

CATIA V5 Design Accelerators in Action

Our accelerator series is a collection of CATIA V5 utilities developed to accelerate productivity and streamline design workflows. These tools leverage CATIA’s Knowledgeware capabilities to automate repetitive, time-consuming tasks that are common in the design process. Developed with our customers in mind, each accelerator helps reduce manual effort and improve consistency empowering engineers to do more with less effort.

Benefits of Accelerators

![]()

Boost Productivity

Manual tasks in CATIA, like renaming parts or creating documentation, can take up valuable engineering time. Our accelerators reduce the time spent on these repetitive actions, allowing designers and engineers to shift their focus to more strategic, value-adding work.

![]()

Get It Right

Every manual click introduces an opportunity for error. By automating standard processes, accelerators help ensure the tasks are done right the first time. Whether it’s generating CNC setup documentation or creating an inspection report, the output is consistent and accurate.

![]()

Consistency at Scale

When teams grow or projects multiply, maintaining consistency becomes a challenge. Our accelerators apply standardized logic and formatting that ensures the process and output are uniform across the user group.

![]()

Ready for Production

Product development doesn’t stop at the 3D model. What happens next is just as critical. These tools support a smooth handoff to manufacturing by generating key manufacturing deliverables, ensuring the production teams receive exactly what they need, when they need it.

Training Course

CATIA Model Based Definition (MBD) Accelerator

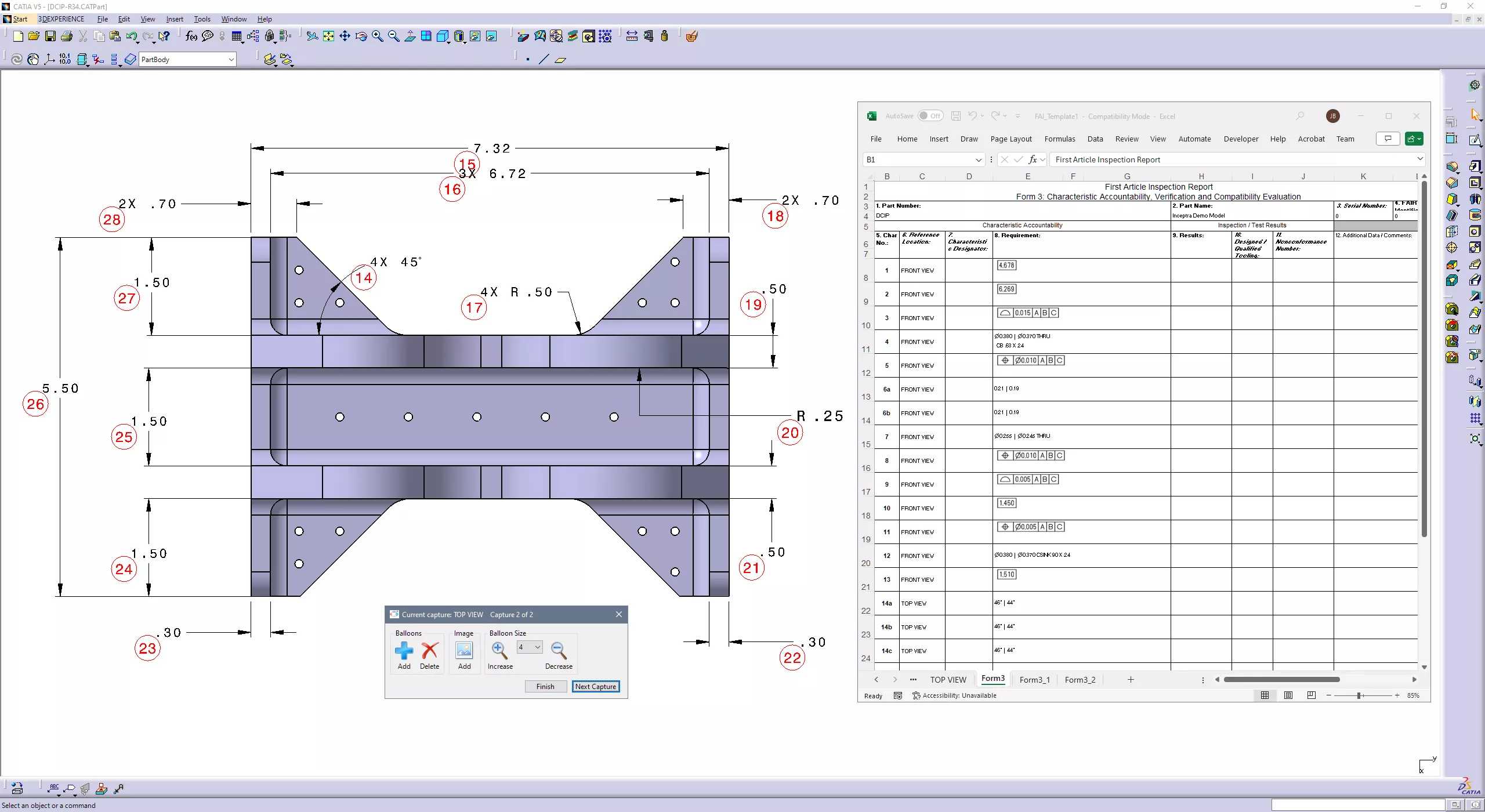

Learn how the GoEngineer MBD Accelerator will extract CATIA model dimensions, notes, and tolerances directly into Microsoft Excel®. See how to extract individual 2D Views from the CATIA MBD data and how to generate a First Article Inspection (FAI) report that includes extracted views with ballooning callouts.

Also learn how to customize the output format produced in Microsoft Excel® to meet your needs or those of your customer.

This class only applies when purchased along with the CATIA V5 MBD Accelerator application license.

Accelerator Series Portfolio

-

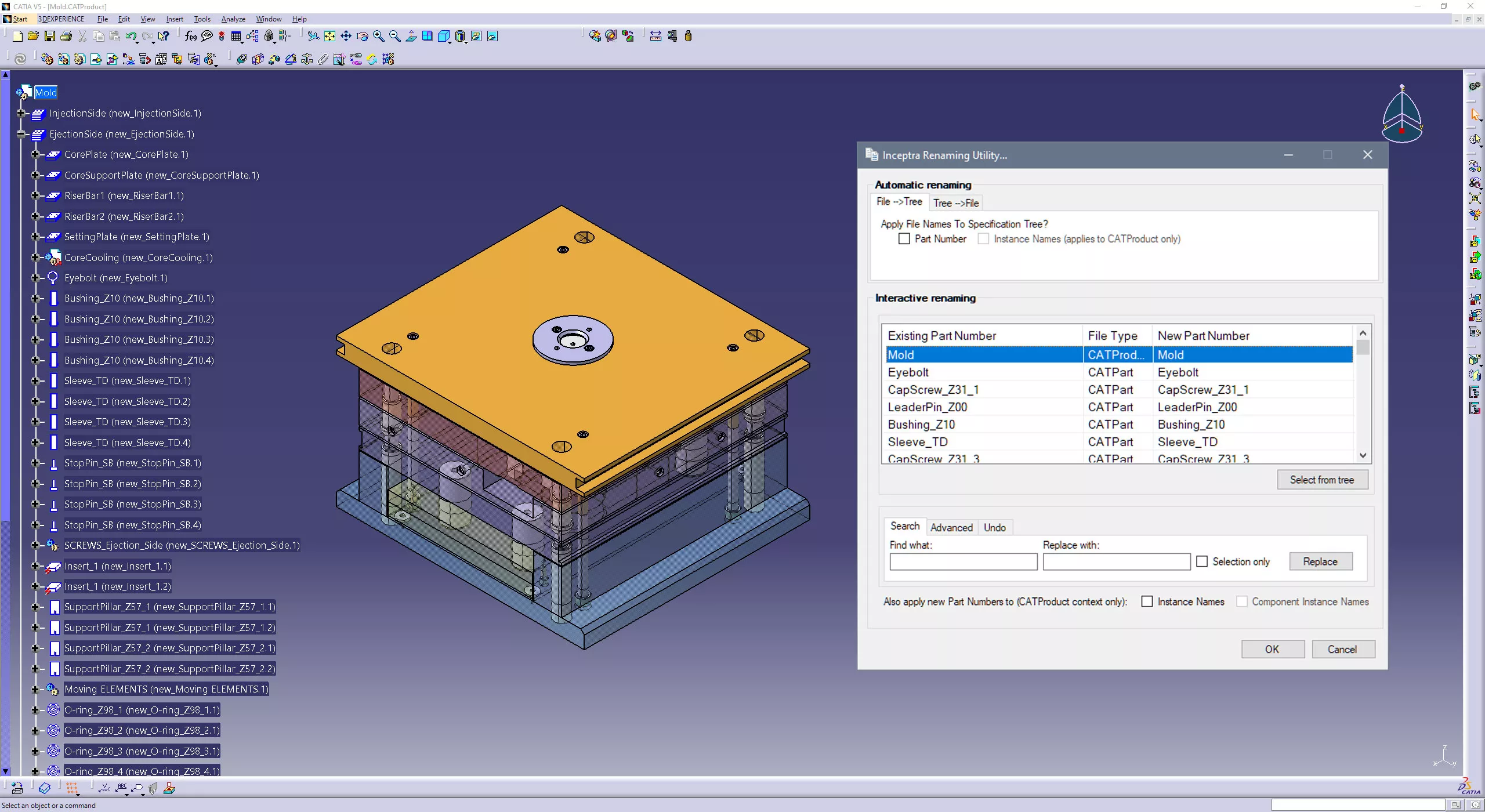

Renaming Utility

- The Renaming Utility saves valuable time by automating the process of managing file names and part numbers in CATIA assemblies. Instead of manually performing “Save Management” or “Send To”, renaming files one by one, and changing each Part Number individually, this tool does it all in just a few clicks.

-

Automate the need to:

- Perform “Save Management” or “Send To” on an assembly

- Rename each file individually

- Open every assembly to manually update Part Numbers

- Change component instance names manually -

Benefits:

- Easy-to-use graphical interface

- Tree-based renaming or “Send to Directory” modes

- Text search & replace capabilities -

-

MBD Accelerator

-

With Model Based Definition (MBD) product development processes, all information to define, manufacture and inspect a part or assembly is contained in the 3D model.

The GoEngineer MBD Accelerator solution for CATIA V5 or ENOVIA DMU streamlines the publishing of your MBD product data throughout your organization by extracting important design information and presenting it in simple, usable formats such as Microsoft Excel®. It enables the quick generation of manufacturing documents and automates the production of First Article Inspection (FAI) reports.

-

Quickly Generate:

- First Article Inspection (FAI) reports for quality

- Shop aids for manufacturing -

Benefits:

- Extraction of GD&T captures, annotations, and notes

- Fully configurable to work with a variety of methods used to create annotations in the model

- Configurable report formats

- Automatic First Article Inspection (FAI) ballooning -

-

Masking Utility

-

The Masking Utility automates tasks for metal finishing applications, generating template documentation that ensures model accuracy, quality checks, and OEM definitions. This solution reduces issues with 2D documentation, such as inaccurate templates, lack of quality checks, and material gouging.

This accelerator streamlines the process of creating flat patterns from complex surface geometry. By allowing users to quickly select surfaces within a 3D model, this tool automatically flattens the geometry and generates a 2D view. This eliminates the need for manual unfolding or work arounds, saving time and ensuring greater accuracy.

Ideal for downstream applications like masking, painting, or manufacturing templates.

See the video above for an overview of the GoEngineer Masking Process Accelerator.

-

-

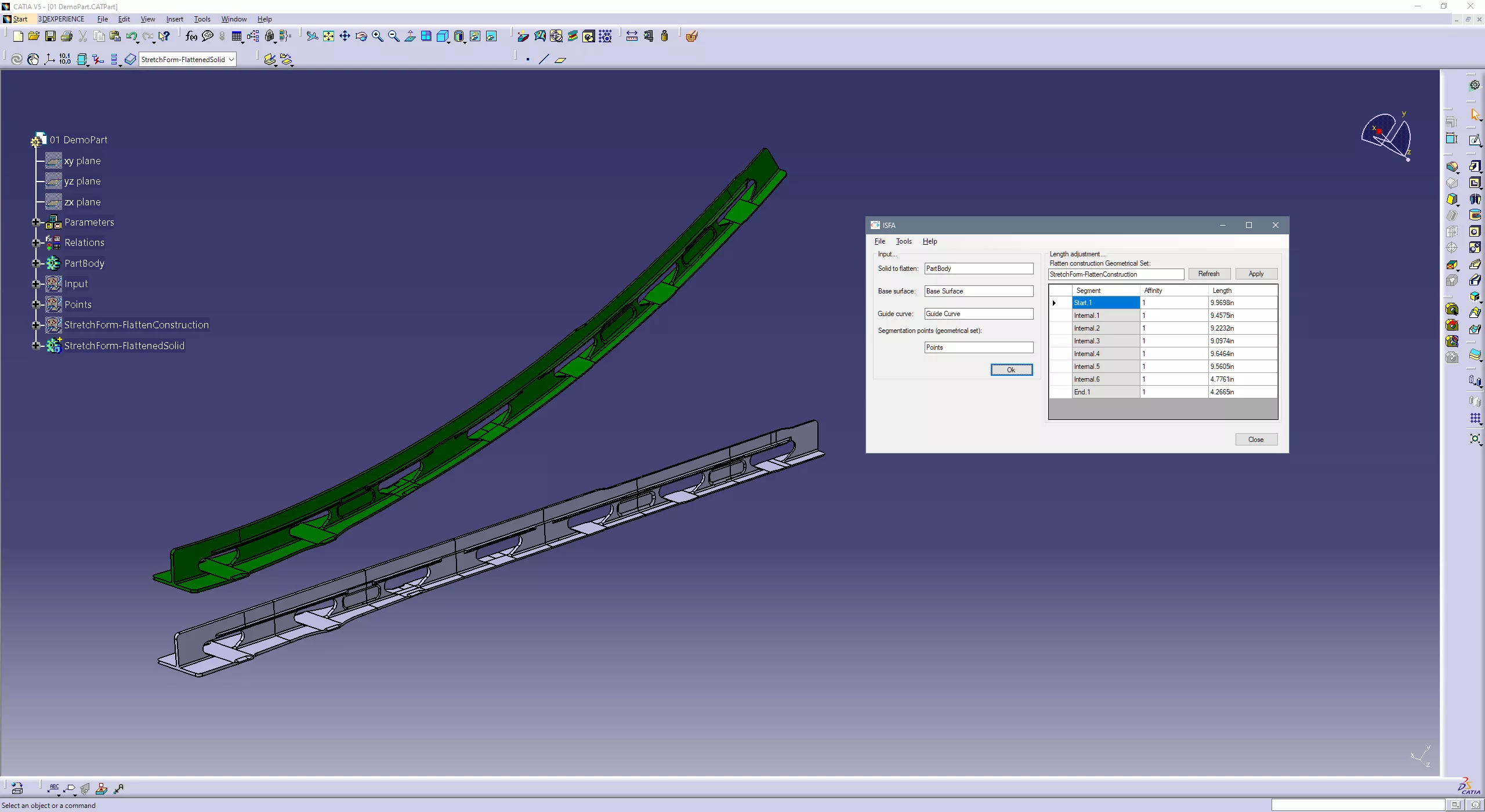

Stretch Form Accelerator

-

GoEngineer Stretch Form Accelerator (SFA) works with CATIA V5 to derive the linear state from formed models of non-uniform cross-sections, commonly found in aerospace parts like stringers, straps, and fuselage components. These parts undergo stretch or roll forming, requiring an intermediary step to obtain the linear shape. Machining the linear part before forming is more cost-effective than machining the finished product.

This application benefits airframe manufacturers who start with extrusion or bar stock to create machined-then-formed parts. It supports various cross-section profiles, including T, L, and Z shapes. Using the customer’s 3D CAD model, GoEngineer® SFA quickly and accurately generates the linear form, producing the extruded "as machined" state for manufacturing.

-

Key Features:

- Works in combination with a CATIA V5 session.

- Limited user input required

- Works on native CATIA V5 or imported geometry such as STEP or IGES

- Creates the linear “As-Machined” state for NC Programming

- Different cross-sections support, T, L, Z, and others

- Multiple direction forming operations supported

- Varying bend allowances can be defined along the part -

Typically used by:

- SOLIDWORKS designers who need simple design verification

- Designers responsible for routing -

-

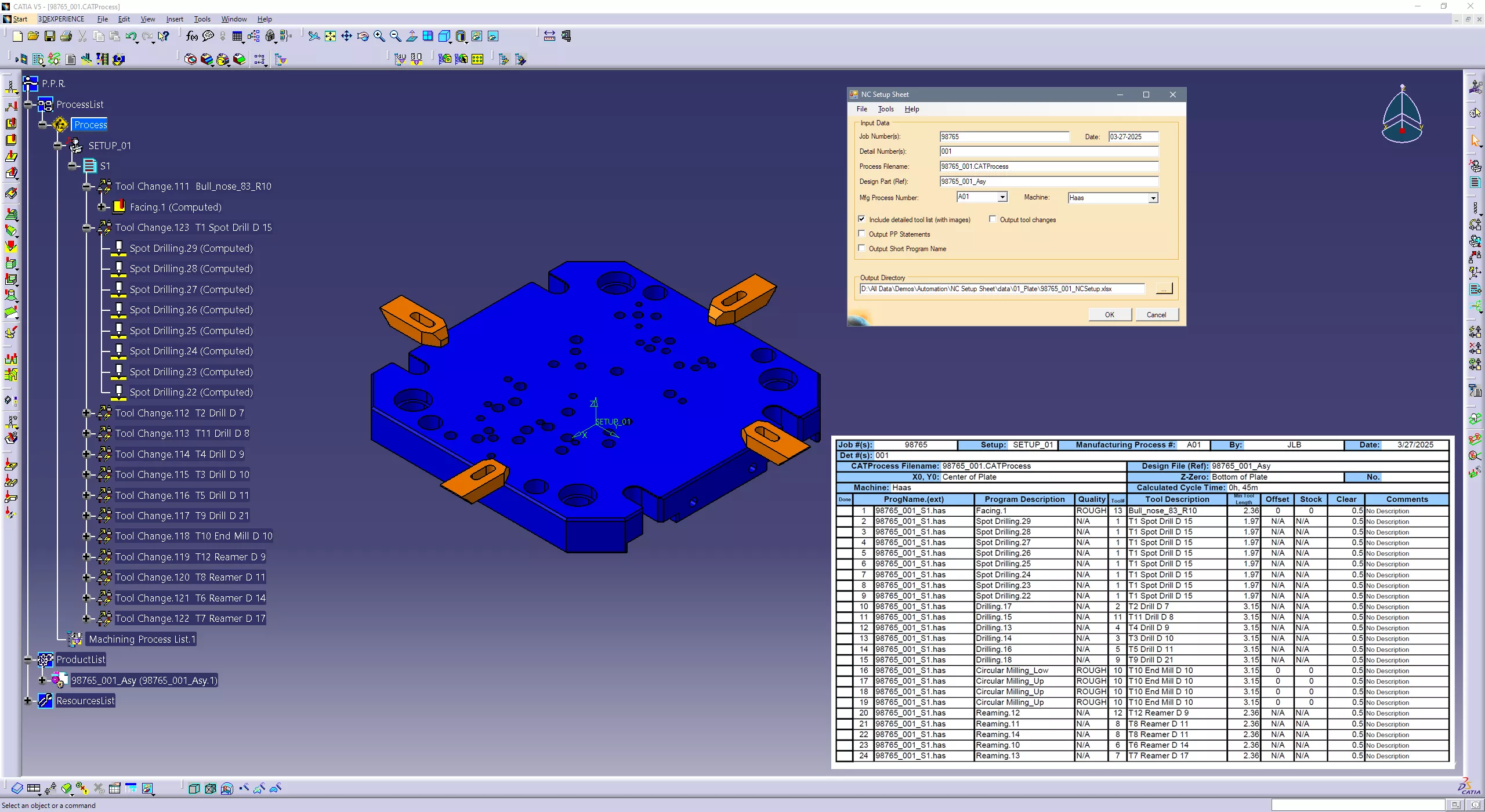

NC Setup Sheet Utility

-

The NC Setup Sheet Utility quicky extracts setup information directly from CATIA machining process, including tool lists and machining operations. Multiple images of the part operation setup can be captured using the intuitive user interface. All extracted information is exported to Microsoft Excel for downstream use by the machine operators.

-

Built on CATIA V5 Architecture:

- Easy to use Graphical User Interface (GUI).

- Fast, reliable data extraction.

- Uniform results every time. -

Automatic output:

- Job Number(s)

- Detail Number(s)

- Setup Name/Number

- Username & Date

- CATProcess file name

- Referenced design file name

- Image(s) of each Setup

- Program Name, Description, Comments

- Machining Quality

- Tool Number, Description, & Length

- Remaining material

- Clearance/Safety Plane dimension

- Manufacturing Process Number

- Machine Descriptions of X0, Y0, Z0 location

- Detailed Tool List (with images and dimensions) -

NEED IMAGE

A Practical Guide to Systems Modeling using MagicGrid

MagicGrid® BOOK OF KNOWLEDGE

The MagicGrid Book of Knowledge (BoK) is a unique, model-based systems engineering (MBSE) experience. This book describes one of a million possible straightforward ways to develop a system model from A to Z. It is an answer to all the questions you may have, starting from “why” and ending with “how”, which few of today’s available sources of information can answer.

Any theory needs practice. An approach becomes useful when it is provided in company with comprehensive instructions on how to use it in practice. The MagicGrid framework for MBSE by CATIA ® Magic is no exception to this rule. This was the main reason we have decided to write this book.

So, if you’re new at MBSE or look forward to learn about the MagicGrid framework from A to Z, this book is for you. This book is for you, too, if you wish to learn how to use CATIA Magic software for MBSE in combination with OMG® Systems Modeling Language (SysML)™ and MagicGrid. This book is for you as well, if you go for comprehensive instructions, illustrated by the case study of modeling an easy-to-understand real-world system

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services