DELMIAWORKS (IQMS)

Comprehensive ERP & MES for Midmarket Manufacturers

Beyond Traditional ERP

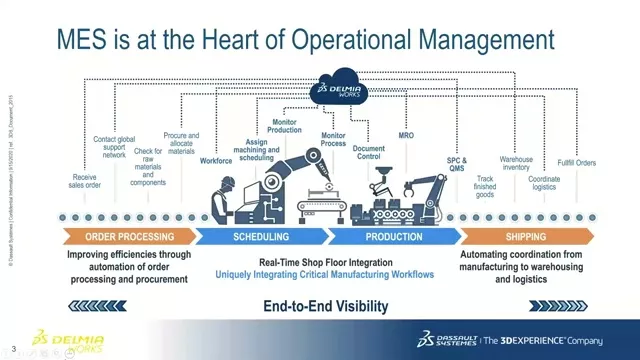

DELMIAWorks, formerly known as IQMS EnterpriseIQ), is an industry-leading enterprise resource planning (ERP) and manufacturing execution system (MES) designed specifically for discrete manufacturers. Built on a single, unified platform, DELMIAWorks provides real-time visibility and control across all aspects of your business, from production and inventory to finance and quality management. By integrating ERP and MES functionalities, DELMIAWorks empowers manufacturers to streamline operations, improve efficiency, and scale seamlessly, all while meeting the unique demands of their industry.

How DELMIAWorks Benefits Your Manufacturing Process

Unified ERP & MES Platform

A single database combining ERP and MES functionality ensures real-time visibility across production and business operations.

Scalability Without Compromise

Designed to grow with your business, DELMIAWorks supports startups to enterprise-level manufacturers with customizable features.

Industry-Specific Focus

Built for manufacturers, DELMIAWorks addresses unique needs such as traceability, compliance, and shop floor optimization.

Real-Time Production Monitoring

Gain actionable insights with real-time shop floor data for smarter decision-making and improved efficiency.

Built-In Quality and Compliance

Advanced quality management tools help maintain stringent compliance standards across industries like automotive, aerospace, and medical devices.

DELMIAWorks Success Story

How to Save $258,000 in Manufacturing Operations

When you are a growing manufacturer of appliance, electrical, transportation, and industrial products with four facilities across North America, you cannot afford to run your operations with an antiquated system that is not keeping pace with the increase in orders and manufacturing activity.

That was the case for Ohio-based Mar-Bal, Inc. That is until they made the switch to DELMIAWorks manufacturing ERP solution, which enabled an increase in operational efficiency, allowing them to keep up with growing demand and generate immediate savings in time and money across the board.

With an annual savings of $258,000 across its four plants and the elimination of idle downtime, Mar-Bal is on the path to success with the capacity to handle additional demand.

Explore DELMIAWorks' Fully-Integrated Approach

A fully integrated ERP system for streamlined manufacturing operations

Designed to meet the specific needs of your manufacturing industry, DELMIAWorks ERP software delivers an innovative shop-floor-first approach, utilizing a single database to eliminate data silos and reduce costly third-party integrations. Click on any of the boxes below to explore each of the modules in detail.

DELMIAWorks eBook

Six Strategies for Maximizing Manufacturing Productivity with Connected Workers

It’s no secret that the manufacturing industry has become more competitive, complex, and unpredictable. There is increasing pressure on manufacturing companies to quickly respond to demand fluctuations, adapt to resource shortages, control costs, and still get quality products out the door on time. By sharing data and insights in real-time anywhere employees need it, manufacturers are breaking down barriers between departments and creating a more adaptive workforce that can:

- Anticipate and act on rapid changes

- Solve problems in real-time

- Maximize resource utilization

- Reduce losses due to poor quality

- Work through complex tasks and prevent human errors

Download this whitepaper to learn how by enabling connected workers, manufacturers can create an ideal environment in which they can excel, despite the rapid changes and unpredictability in the manufacturing supply chain.

Take the DELMIAWorks Department Tour

See how DELMIAWorks touches (and benefits) so many aspects of the business.

DELMIAWorks for Your Industry

Plastics

Plastics processors constantly battle volatile resin prices, high scrap rates, and the complexity of multi-cavity molding operations. Family molds, multi-step bills of material, and frequent unit-of-measure conversions add chaos to production.

DELMIAWorks – born on the shop floor of plastics plants – tackles these challenges head-on. RealTime machine monitoring gives you instant insight into cycle counts, downtime, and yields, while drag-and-drop scheduling built for cavitation and family tools helps maximize capacity. The system tracks regrind and material blends automatically, so you can minimize waste and control costs without compromising on quality or delivery performance.

DELMIAWorks Industry Success Story: Gamsee

Injection molding company improves margins and profitability, automates production operations, and accelerates growth.

Medical Devices

Medical device manufacturers face intense regulatory scrutiny and cannot afford lapses in quality or traceability. Meeting FDA mandates and ISO 13485 standards means every lot, document, and step must be tracked with precision.

DELMIAWorks embeds compliance into its core. Its Quality Management suite covers ISO/FDA requirements – from electronic signatures and audit trails to CAPA and risk management. The fully integrated Device History Record (DHR) module automatically compiles the production history of each device, eliminating paper binders and human error. When a surprise audit or recall looms, DELMIAWorks users know they can rapidly prove control over their processes and products.

DELMIAWorks Industry Success Story: Comar

By harnessing data in the DELMIAWorks (formerly IQMS) manufacturing ERP system, COMAR LLC has the real-time insights to drive innovation, ensure the quality that differentiates it from competitors, and enable the agility to address customers’ demands.

Automotive

Automotive suppliers operate under unforgiving demands for zero defects and just-in-time delivery. They juggle complex EDI schedules, ever-changing customer requirements, and stringent standards like IATF 16949.

DELMIAWorks streamlines these pressures with a single, automotive-focused ERP/MES solution. It automates customer EDI and labeling compliance – from schedules and ASNs to barcoded shipping labels – ensuring every shipment meets OEM mandates. Integrated quality tools (APQP, SPC, full traceability) keep defect rates at zero even at high volumes. And with real-time production and inventory visibility, you can respond immediately to changes in demand and avoid costly line stoppages.

DELMIAWorks Industry Success Story: Nissen

Learn how Nissen Chemitec America reduced EDI monthly cost by 90% and eliminated most shipping errors.

Metals & Stamping

Metal stamping manufacturers stay lean whether producing one-off parts or stamping out thousands per hour. Material costs are high and margins tight, so scrap and rework eat into profit. They also juggle raw stock in pounds vs finished pieces in units, complicating inventory tracking.

DELMIAWorks tames this complexity with flexible unit-of-measure conversions and scrap tracking – every pound of material is accounted for automatically. Its multi-level BOMs handle progressive dies and family tools, while real-time production monitoring and tool maintenance scheduling prevent unplanned downtime. The result is less waste, predictable costs, and a shop floor that can adapt quickly to customer needs.

Aerospace & Defense

Aerospace and defense manufacturers face complex global supply chains, aggressive delivery schedules, and strict compliance obligations. Long program lifecycles and regulations like ITAR and AS9100 demand rigorous tracking of every part and process.

DELMIAWorks unifies data from engineering through delivery and offers detailed MRP planning to anticipate material needs and manage complex assemblies without excess inventory. Compliance is built in – export-controlled orders are flagged for ITAR, and the quality system meets aerospace standards for safety and traceability. 24/7 supplier portals and two-way EDI keep you connected with suppliers, so production stays agile and auditable even in a cyclical market.

DELMIAWorks Industry Success Story: Apple Rubber

Learn how a centralized system provides real-time visibility and traceability into all aspects of Apple Rubber's business.

DELMIAWorks eBook

Understanding the ROI of Manufacturing ERP

From the sales quote through production, shipping, and cash receipts, ERP has the potential to significantly impact processes, productivity and profits. The problem many people struggle with is how can you put a dollar figure to the potential return on your investment?

Download the whitepaper, 8 Essential Value Propositions of Manufacturing ERP, to better understand the financial benefits and impacts of manufacturing ERP on everyday operations, including:

- How improving inventory turns can save $150,000 a year and free up cash for other business investment

- How eliminating a 5% error in standard costs can result in an additional $700,000 in annual profits

- How improving scheduling accuracy and eliminating unplanned downtime can create $3-5 million a year in opportunities

- How reducing production defect rates can lower the cost of poor quality by up to $600,000 a year

- How reducing quoting errors by 5% can increase profitability by $350,000

DELMIAWorks eBook

Six Strategies for Maximizing Manufacturing Productivity with Connected Workers

It’s no secret that the manufacturing industry has become more competitive, complex, and unpredictable. There is increasing pressure on manufacturing companies to quickly respond to demand fluctuations, adapt to resource shortages, control costs, and still get quality products out the door on time. By sharing data and insights in real-time anywhere employees need it, manufacturers are breaking down barriers between departments and creating a more adaptive workforce that can:

- Anticipate and act on rapid changes

- Solve problems in real-time

- Maximize resource utilization

- Reduce losses due to poor quality

- Work through complex tasks and prevent human errors

Download this whitepaper to learn how by enabling connected workers, manufacturers can create an ideal environment in which they can excel, despite the rapid changes and unpredictability in the manufacturing supply chain.

Putting a dollar figure on ROI

Download the whitepaper to better understand the financial benefits of manufacturing ERP including:

- Saving $150,000 a year by improving inventory turns.

- How eliminating a 5% error in standard costs can result in an additional $700,000 in annual profits

- How improving scheduling accuracy and eliminating unexpected downtime can create $3-5 million a year in opportunities

- How reducing production defect rates can lower the cost of poor quality by up to $600,000 a year

- How reducing quoting errors by 5% can increase profitability by $350,000

Frequently Asked Questions

Stop Flying Blind: Gain Visibility into Your Manufacturing Operations with DELMIAWorks

One of the greatest challenges manufacturers face is the lack of visibility into their manufacturing operations. Learn how DELMIAWorks Manufacturing ERP provides that visibility to increase efficiency and profitability by:

- Tracking production status in real-time

- Ensuring material, equipment, and labor are available to meet demand

- Enabling consistent and timely communication across the supply chain

- Identifying bottlenecks and constraints that might affect the production schedule

- Eliminating waste and control costs

- Producing quality parts on time, every time

Putting a dollar figure on ROI

Download the whitepaper to better understand the financial benefites of manufacturing ERP on everyday operations including:

- Saving $150,000 a year by improving inventory turns.

- How eliminating a 5% error in standard costs can result in an additional $700,000 in annual profits

- How improving scheduling accuracy and eliminating unexpected downtime can create $3-5 million a year in opportunities

- How reducing production defect rates can lower the cost of poor quality by up to $600,000 a year

- How reducing quoting errors by 5% can increase profitability by $350,000

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services