HP 3D Printers

Precision, Speed, and Strength in Every 3D Printed Part

Available in Canada Only

Available in Canada Only

Manufacturing Your Future From Adoption to Scale

HP Multi Jet Fusion (MJF) technology is transforming how businesses design, prototype, and manufacture parts. Delivering unmatched speed, preicison, and part consistency, MJF enables movement from concept to production up to 10x faster. Voxel-level control allows fine-tuning of material properties for functional, high-performance, and customized parts. Trusted across aerospace, automotive, healthcare, and consumer products, HP's 3D printing solutions drive the future of additive manufacturing.

Voxel-Level Precision for tailored part properties

HP MJF technology gives manufacturers complete control over individual voxels, allowing fine-tuning of material properties within each part. This enables functional grading, customized performand, and optimized mechanical properties.

High-Speed Production For Rapid Turnaround

MJF accelerated printing by using precise thermal energy to fuse powder across the entire layer simultaneously, enabling production up to 10x faster than traditional 3D printing methods.

Consistent Quality Across Parts

Integrated quality controls and uniform energy application ensure repeatable results, even for complex geometries and large builds.

Scalable Solutions For Every Application

HP MJF technology delivers fast, precise, and reliable 3D printing that scales from prototypes to full production. Its versatility and consistent performance make it ideal for a wide range of applications across multiple industries.

HP 3D Printers

-

-

HP Jet Fusion 5000 Series

- Technology:

MJF - Build Volume:

15" x 11.2" x 9.8" -

Features:

Scalable, high-performance 3D printing made simple. -

HP 3D MATERIALS

-

High Reusability PA 11

- Available with: 5000 / 5200

- Potential Applications:

– Orthotics & prosthetics

– Automotive components

– Consumer products

– Jigs & fixtures

-

Produce strong, ductile, and chemically resistant functional parts with bio-based thermoplastics for HP Multi Jet Fusion. Enjoy high performance, reusability, fine detail, and industry-standard compliance with reduced environmental impact.

-

High Resuability PA 12

- Available with: 5000 / 5200 / 5600

- Potential Applications:

– Medical & healthcare devices

– Electronic products

– Industrial & functional prototypes

– Automotive components

-

Produce strong, functional, and chemically resistant parts with HP Multi Jet Fusion. This robust, low-cost thermoplastic delivers high-density, detailed components with excellent reusability, bio-compatibility, watertight properties, and a reduced environmental footprint.

-

High Reusability PA 12 S

- Available with: 5000 / 5200 / 5600

- Potential Applications:

– Dental & healthcare

– Functional prototypes

– Electronic products

– Consumer goods

-

Produce high-quality, functional parts with premium surface aesthetics. This material delivers fine detail, dimensional accuracy, and smooth surfaces, while reducing costs, maximizing powder reusability, and supporting sustainable, low-waste production.

-

High Reusability PA 12 Glass Beads

- Available with: 5000 / 5200

- Potential Applications:

– Automotive parts

– Functional prototypes

– Fixtures & tooling

– Enclosures & housings

-

Produce stiff, functional parts with high dimensional stability and repeatability using HP Multi Jet Fusion. This 40% glass bead-filled thermoplastic delivers strong mechanical performance, fine detail, and up to 70% powder reusability for cost-efficient, sustainable production.

-

High Reusability PP

- Available with: 5000 / 5200

- Potential Applications:

– Medical & healthcare

– Consumer goods

– Industrial & functional parts

– Automotive components -

Produce functional polypropylene (PP) parts with HP Multi Jet Fusion, offering chemical resistance, low moisture absorption, and high powder reusability for versatile, cost-efficient applications.

-

High Reusability PA 12 White

- Available with: 5420

- Potential Applications:

– Consumer products & electronics

– Automotive components

– Functional prototypes

– Medical & healthcare devices

-

Produce strong, high-density functional parts with excellent mechanical properties and a bright white finish designed for aesthetic-critical applications. This versatile material offers reliable performance, customizable colour options, and is optimized for industrial additive manufacturing.

HP APPLICATIONS

Orthotics & Prosthetics

Use HP MJF to deliver custom, high-quality orthotics and prosthetics. Precise, durable, and tailored for every patient.

Drones

HP Multi Jet Fusion technology helps you design and produce lightweight, durable drone parts faster. Ready for flight and built for performance.

Consumer Goods

Bring custom, high-performance consumer products to market faster with HP MFJ technology. Think eye-catching cases, premium housings, and limited-edition gear built both beautifully and efficiently.

Healthcare & Medical

HP Multi Jet Fusion enables healthcare professionals to produce precise anatomical models, custom medical devices and patient-specific prosthetics, faster, smarter and with exceptional detail.

Software

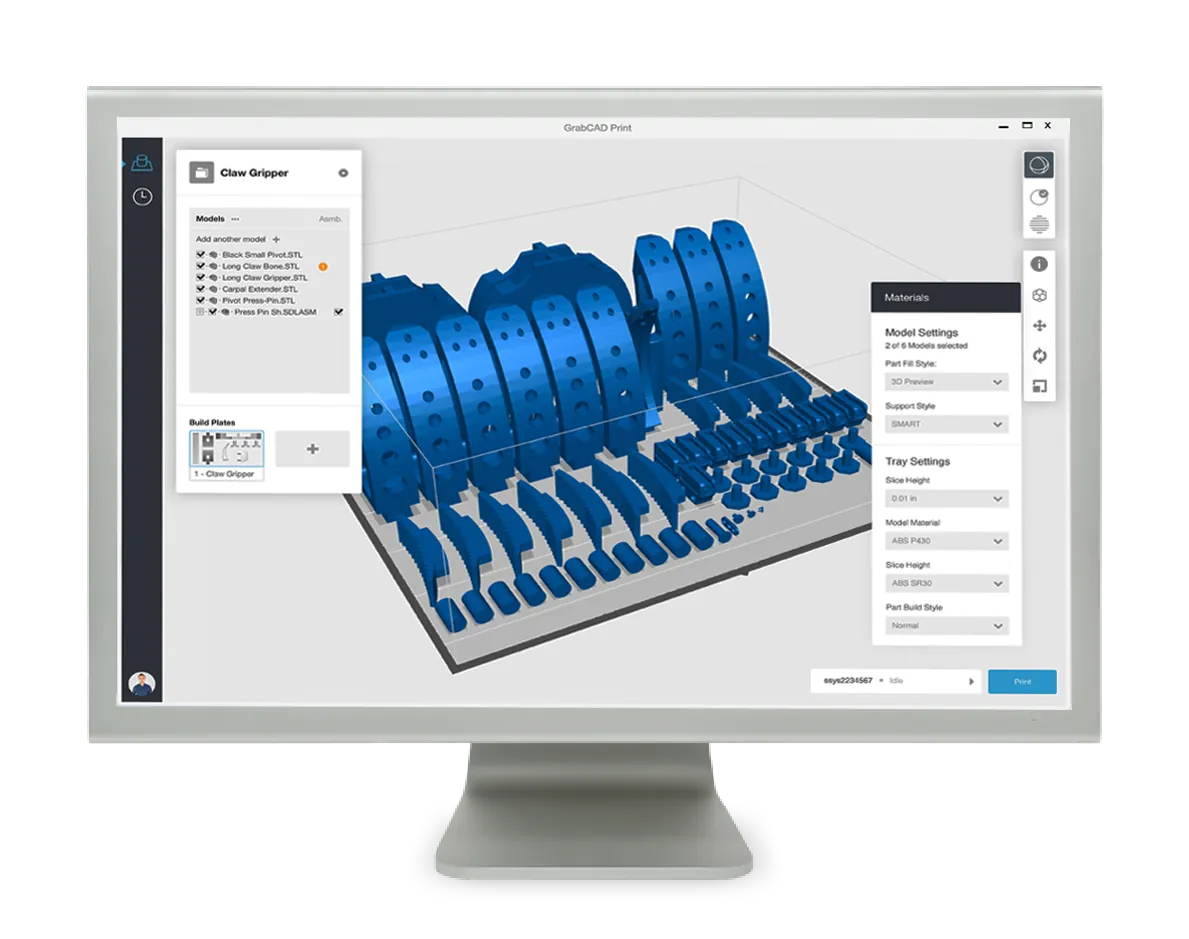

GrabCAD Print

Professional 3D Printing Made Easy and Accessible

GrabCAD Print is the most complete solution for Stratasys 3D printers on the planet. The intuitive, easy-to-use software allows for simplified preparation, scheduling, monitoring, and reporting of print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management in shared office and model shop environments.

INSIGHT SOFTWARE

OPTIMIZE BUILD OUTPUT FOR 3D PRINTING

(ONLY AVAILABLE ON F370) Insight software prepares your CAD program’s STL output for 3D manufacturing on a Fortus machine by automatically slicing and generating support structures and material extrusion paths. For maximum control, users can manually edit parameters that determine the look, strength, and precision of parts as well as the speed and material use of the FDM process.

- Optimize build orientation for maximum strength and smoothest surface finish

- Customize supports for fast, easy removal and best use of materials

- Program pauses into the build for any reason, such as to embed hardware or circuitry

- Manipulate tool paths for advanced control over part properties

Included with Insight is Control Center. This sophisticated software application communicates with user workstations and Fortus systems, to manage jobs and monitor production status. Design, engineering, and manufacturing teams can network and share 3D manufacturing capacity to maximize efficiency and throughput.

*Compatible with GrabCAD Print for use with job reports, scheduling, and remote monitoring.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services