DyeMansion Powershot C Consumables Stream: How It Works

The DyeMansion Powershot C is an automated depowdering solution for parts 3D printed on the Stratasys H350 or another laser sintering printer. Though much of the unused Nylon powder can be recirculated into the printer, there will always be some residual powder that has adhered to the surface of parts coming out of the machine. Removing that powder is either a tedious, manual process or requires post-processing equipment. It can be daunting to add a new piece of unfamiliar equipment to your workflow, with its own operation and consumable nuances.

The Powershot C uses an automated tumbling and blasting process in conjunction with its proprietary PolyShot PC4 media. Below is a step-by-step explanation of how media goes into and out of the Powershot C.

Loading PolyShot Media Into the Machine

- Depressurize the system by pressing the red off button.

- Depressurization is confirmed with a satisfying pneumatic hissing sound (and the pressure gauge will fall to zero).

- Locate the hopper on the left side of the machine and unlatch the door.

- Pour the PolyShot PC4 media into the hopper.

- Close the hopper and return to the front of the machine.

- Press the Reset button to repressurize the system.

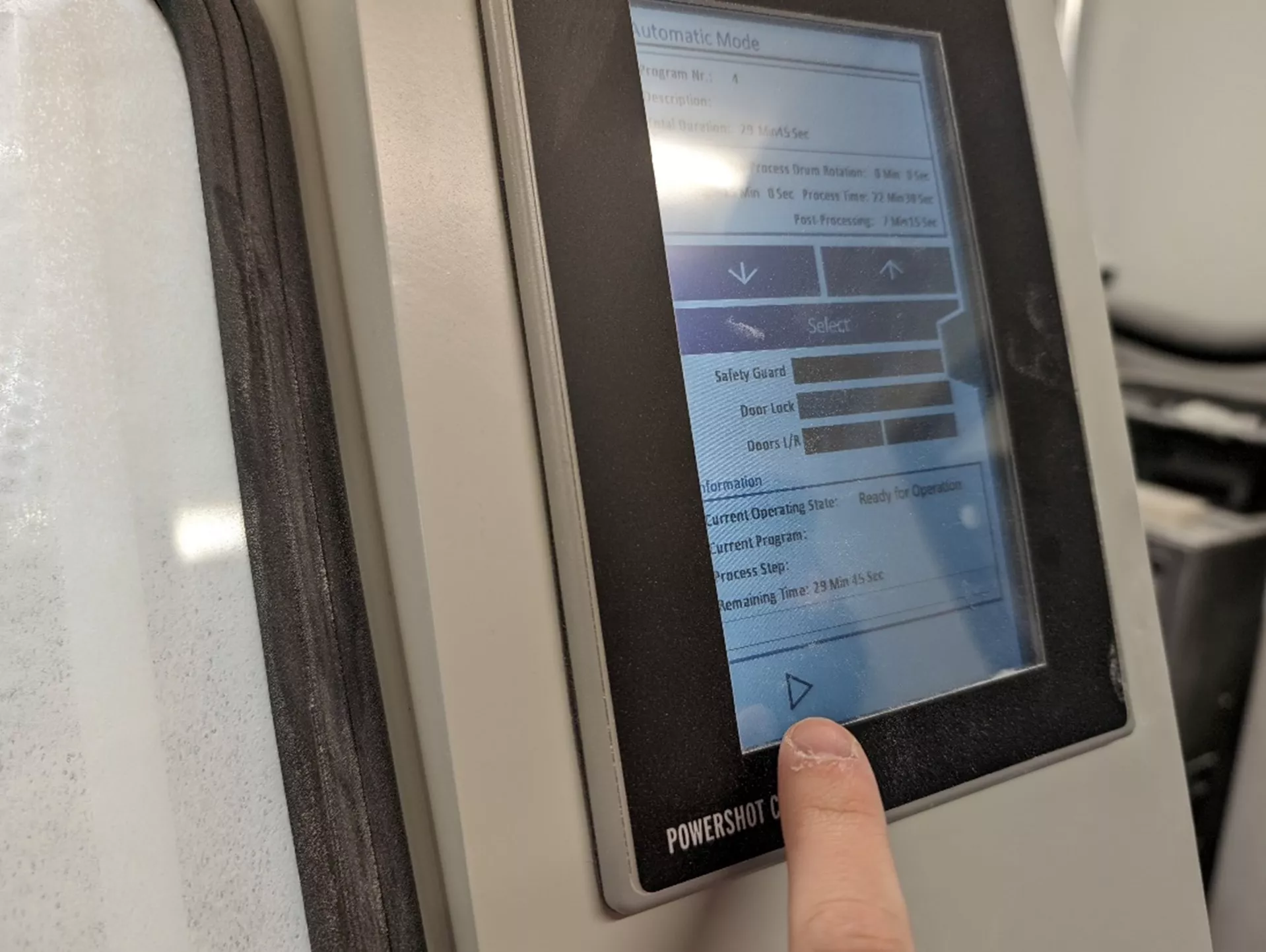

- Choose the appropriate cleaning recipe on the user interface and start the cleaning cycle.

Managing waste from this process is essential to keeping the machine operating reliably. The DyeMansion Powershot C accumulates a mixture of two waste products: PolyShot media and the Nylon powder that was cleaned off the 3D printed parts.

The Powershot efficiently recirculates intact PolyShot media and discards media that has fractured during the cleaning process. Once the media is fractured, it becomes far less effective at cleaning, so it gets filtered out of the system, along with the Nylon powder. The machine channels the waste to a wheeled, removable waste container.

Removing Waste PolyShot Media and Nylon Powder from the System

- Depressurize the system by pressing the red off button.

- Confirm system depressurization.

- Locate the dust bin on the right side of the machine and flip the two latches that hold it in place.

- Roll the dust bin out of the machine.

- Remove the waste material with one of two methods:

- Remove and discard the waste bag (and its contents)

- Be sure to add a new bag when complete.

- Keep the bag in the waste container and use a shop vacuum to remove the waste.

- Remove and discard the waste bag (and its contents)

- Replace and relatch the waste container.

- If the machine will be used for additional cycles, press the Reset button on the front of the machine to repressurize the system.

The expected lifespan of PolyShot media is entirely dependent on the amount of residual nylon powder that is being cleaned off of parts. We find that operating the SAF printer (or other laser-sintering machines) outside its recommended environmental conditions (like ambient temperatures and humidity) results in more powder sticking to the parts.

In addition, making sure to set the proper chamber temperature for the density of each build is crucial for minimizing residual nylon. The cleaner the parts that are loaded into the DyeMansion Powershot C, the longer you can prolong the life of the PolyShot media.

The ability to clean hundreds of parts per hour in a hands-off cycle has fundamentally changed the way I think about high-volume 3D printing production. If time, labor, and consumable efficiency are valuable to you and your organization, look no further than the DyeMansion Powershot C.

Questions?

If you have questions or would like to learn more about the Powershot C or any other piece of post-processing equipment from DyeMansion, please contact us.

3D Printing as a Service

GoEngineer offers comprehensive 3D printing services across multiple U.S. labs, equipped with cutting-edge Stratasys FDM, PolyJet, Stereolithography, P3, and SAF technologies for 3D printed prototypes or production parts. Request your quote online today!

Related Articles

Stratasys Separator DM for Acrylic Orthodontic Appliances

How 3D Printing is Helping Manufacturers Fight Back Against Tariffs

Experts in Additive: 3D Printing with GoEngineer

Economic Change in Manufacturing Demands a New Approach by Leveraging 3D Printing

About Simon Pinter

Simon Pinter is a Manufacturing Solutions Application Engineer at GoEngineer

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.