Is Bad Version Control Costing Your Engineering Team?

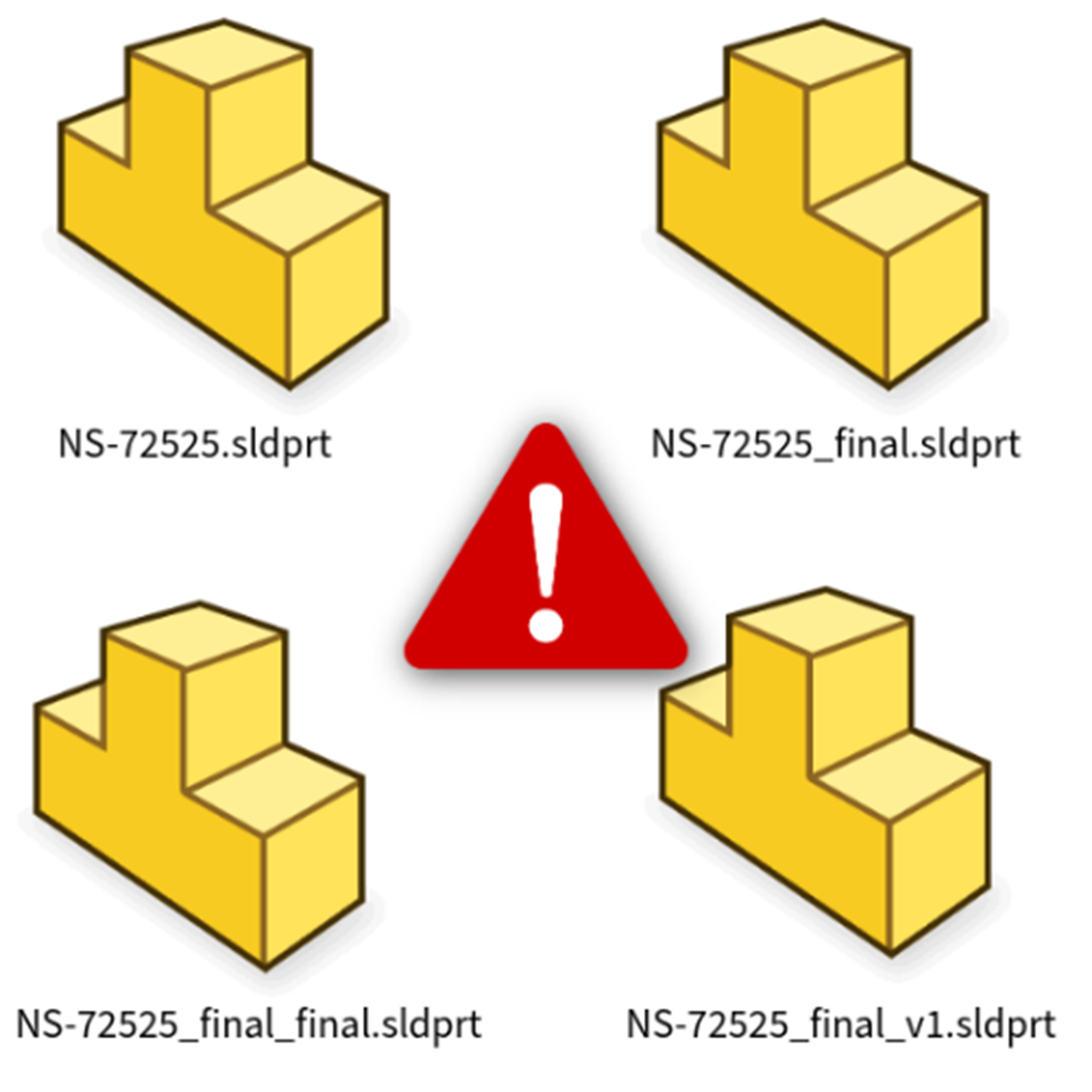

I was recently looking for a file on my computer that I wanted to share on LinkedIn. After a while, I finally found it! Or wait… maybe it’s this other file. How could I not tell? One file was named “vid-for-linkedin-final-final” and the other was named “vid-for-linkedin-final-v1”. So, which one was the right version?

My own experience searching for a "final" video file is a daily reality for engineers. Poor version control directly translates to lost time, productivity, and money. Here’s how:

The Tangible Costs: What You’re Really Losing

Lost Time and Productivity

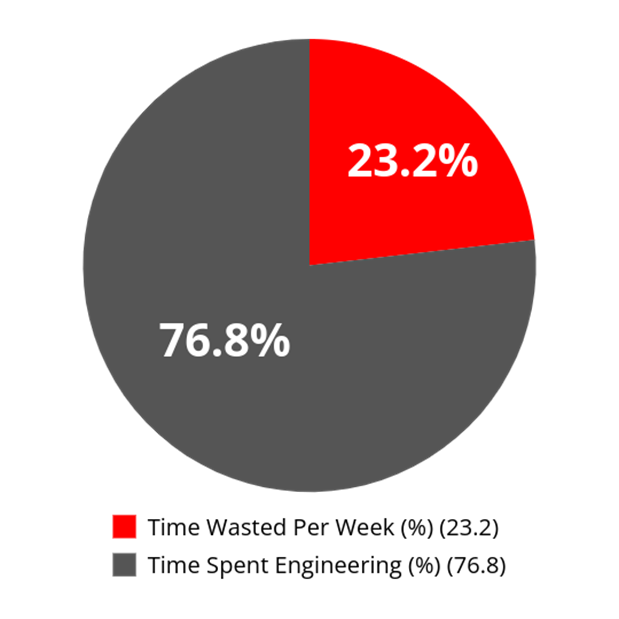

Struggling to find the right file is never just a one-time inconvenience. If you dig through disorganized files once, you’ll do it again. A McKinsey study confirms this: employees spend an average of 23.2% of their week simply searching for the data they need. That's nearly a full day every week spent just trying to find a file, instead of designing.

Recreating Lost Work

What happens when you can’t find the "correct" final version? Often, engineers resort to recreating the design. This creates multiple problems:

- Compliance Burden: In highly-regulated industries, recreating a file means re-entering the full, time-consuming approval process to maintain compliance.

- Wasted Effort & Money: Work that was already done once now consumes valuable time and resources again. At $45/hour, recreating just one hour of work costs $45 – plus the opportunity cost of falling behind. If this happens just once per week, that’s over $2,200 wasted per engineer annually.

Manual File Management

Beyond searching, day-to-day file management drains productivity. According to Tech-Clarity, manufacturers report that their engineers spend 32% of their time on non-value-added work. Tasks like renaming files, copying to folders, or maintaining manual records don’t add value, yet they consume a third of an engineer's time and introduce costly errors.

Delays in Project Timelines

These individual inefficiencies cascade into significant project delays. While your team might implicitly account for hours of searching, rework, and manual file management when quoting projects, this doesn't have to be the norm. Eliminating these hidden costs of poorly managed SOLIDWORKS versions allows you to quote more competitively, win more business, and accomplish more with less effort.

Financial Impact

Beyond just lost time, these issues hit your bottom line hard. Consider this: organizations estimate that they lose more than $5 million annually due to poor data quality. How exactly does that happen?

Increased Labor Costs

A designer’s salary is best used to pay them to do what they do best – design. But when your engineers have to reorganize, rename, and find files, that’s not design engineer work. Instead, that’s “file janitor” work that you could pay an intern to do (or automate it). The cost of labor directly affects the bottom line, and you want to make sure you’re maximizing your designer’s time, not paying them to do something as trivial as adding files to new folders for tracking purposes.

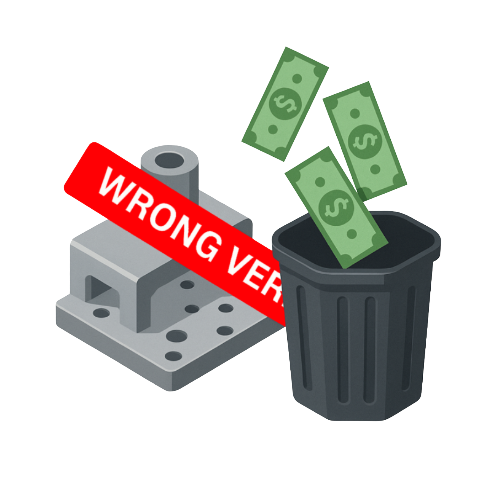

Scrap and Rework

We’ve talked about the costs of when the designer can’t find the right file, but let’s talk about the opposite. In this case, the designer thinks they have found the right file, so they send it to manufacturing for fabrication. According to the American Productivity and Quality Center, scrap and rework costs manufacturers up to 2.2% of annual revenue. For a company with $1 billion in revenue, that’s a staggering $22 million in added costs!

Scrap and rework costs manufacturers up to 2.2% of annual revenue.

Missed Market Opportunities

When your design and engineering teams spend time on non-value-added tasks, they aren’t free to do what they do best – design and innovate. If you could free up 10% of your engineering time to work on innovation, what do you think your team could accomplish?

That time could easily be spent bringing your designs to market faster, giving you a competitive advantage. Alternatively, your team could come up with new opportunities, allowing you to enter the market before anyone else considers what your team came up with.

IT Overhead

I just saw this the other day–dozens of files were accidentally deleted from a shared folder; far too much work to recreate by hand. Luckily, the IT department performs regular backups, so it was as easy as asking them for help with restoring the data. Sure, this time is part of their job, but does it have to be? If proper safeguards were in place, those files wouldn’t have been deleted in the first place, leaving IT to work on other important tasks.

The Intangible Costs: Beyond the Bottom Line

Frustration and Morale

When your team deals with a lot of repetitive work and avoidable issues, it starts to wear on them. Eventually, these inefficiencies drive talent away. A 2024 Teamwork Research Report revealed that nearly 3 in 5 employees have actively thought about leaving their current jobs or applied to new positions due to bad teamwork. These issues surrounding poor version management tend to stem from a lack of communication.

Collaborative Breakdowns

Communication is critical to effective design and engineering. When communication breaks down, you lose your rhythm and struggle to get anything done as quickly as you need. When you have conflicting versions, or you don’t know which version is actually the most recent, you begin to lose trust in your communication system and trust in your data.

Lack of Trust in Data

When engineers don’t trust their data, they verify everything manually, slowing work and increasing errors. This is a common issue; 50% of engineers lack trust in the data they rely on the most in their central system of record. If your engineers don’t trust the data, they’ll spend more time manually verifying, creating their own copies, or making suboptimal decisions.

Risk and IP Protection

While turnover and poor communication are frustrating for your business, this is perhaps the greatest risk to your organization. Poor version control, and thus, poor data management, exposes your company to unnecessary risk. Think about this: when your team is working in an uncontrolled environment, you run into numerous risks.

- Anyone on your team has uncontrolled access to sensitive design files.

- You run into difficulty tracking who accessed/modified what, making it hard (or impossible) to prove ownership or identify bad actors.

- You lack a robust audit trail for compliance or legal disputes.

These issues leave you vulnerable to enormous risks when you don’t need to be open to them. If you implement a proper data management solution, you can get your versions completely under control, boost team morale, and save your company from massive headaches down the line.

Uncontrolled Access

= Unnecessary Risk

The Solution: How SOLIDWORKS PDM Solves Version Control

Problems like we’ve talked about so far are normal, but they don’t have to be. So, how do leading companies overcome these challenges? With a robust Product Data Management system like SOLIDWORKS PDM.

Core Features of SOLIDWORKS PDM

SOLIDWORKS PDM locks down your files in a secure, controlled environment. It doesn’t have to be restrictive either. On the contrary, we’ve highlighted the myriad of problems associated with uncontrolled files; PDM simply adds structure where there previously wasn’t. Here are a few of the key features you should know about with SOLIDWORKS PDM:

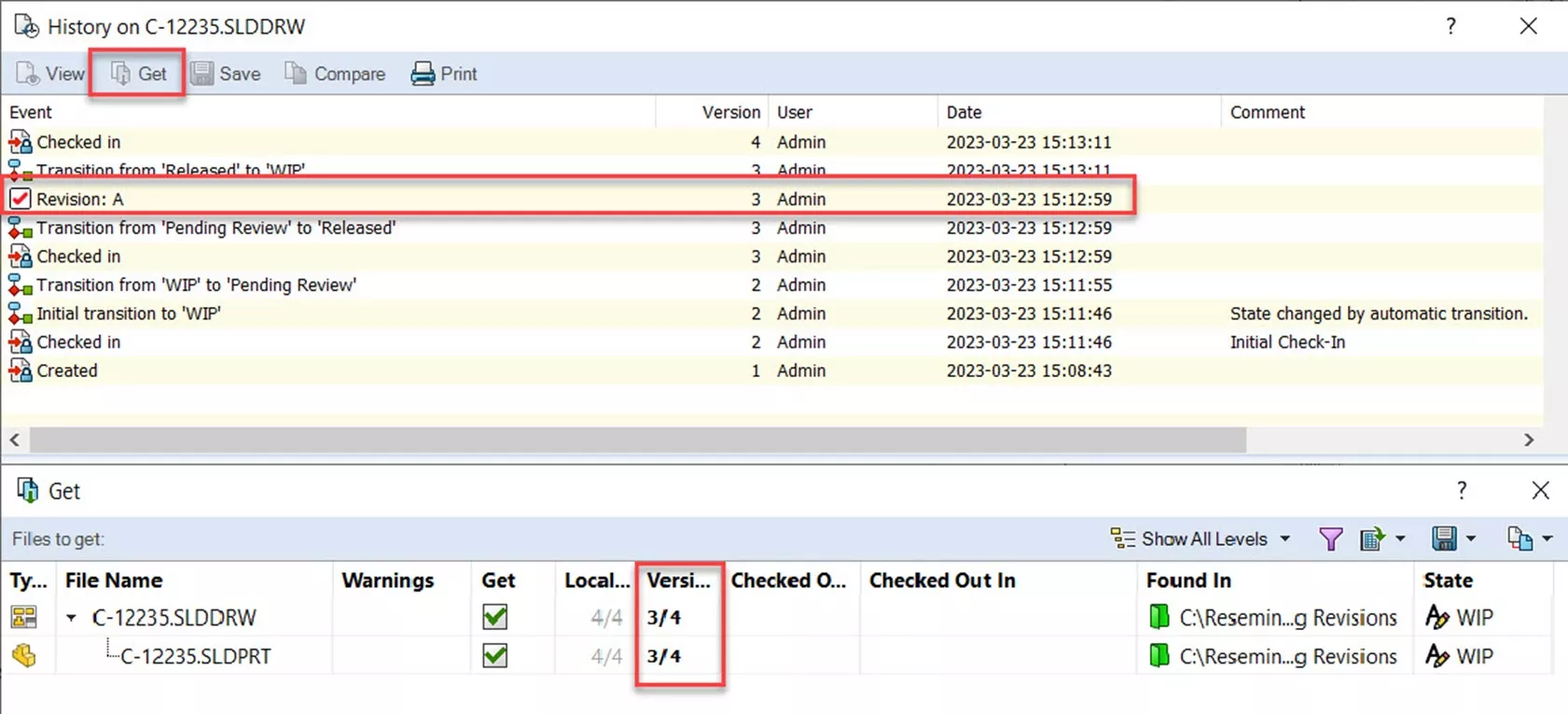

- Automatic Versioning: Each time a file is checked in (put back into the vault), PDM creates a new version. This preserves a complete file history without any manual effort. Additionally, the files don’t have that annoying “final_1” at the end. They preserve their original file name from start to finish.

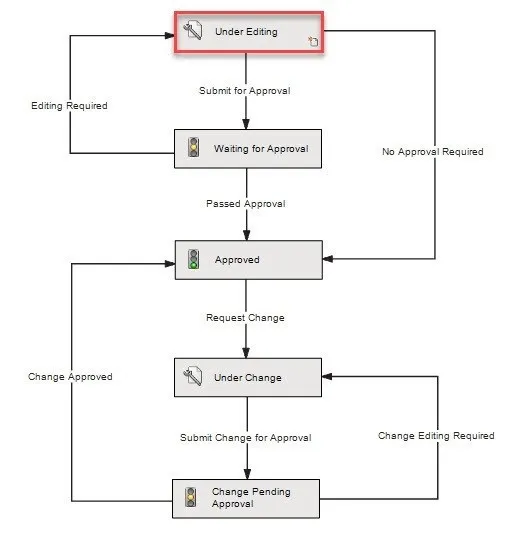

- Revision Control & Workflows: SOLIDWORKS PDM also keeps track of your revisions automatically through the use of defined workflows. These workflows can act as your approval process, ensuring that when a file reaches the “approved” stage of its lifecycle, that information is automatically tracked.

- Check-In/Check-Out: I mentioned that checking a file into the vault creates a new version. With SOLIDWORKS PDM, you only have write access to a file when you check it out. Just like a library book, only one person can check it out at a time, and you have full traceability as to who checked it out and when.

- Complete File History: Because every action is tracked automatically, SOLIDWORKS PDM provides a complete history of your files, resulting in a complete audit trail, the ability to revert to old versions if necessary, and an understanding of your file lifecycle in a single location.

- Robust Search Tool: With the SOLIDWORKS PDM search tool, you can search for your files and easily find what you’re looking for. The beauty of PDM is that it’s built on a back-end SQL database, so you can search on any piece of metadata to find a file. Whether it’s author, description, approval status, file name, etc.

Beyond Version Control: Additional PDM Benefits

While version control is our primary concern in this article, I also want to touch on a few other key benefits of SOLIDWORKS PDM that your team will love.

- Enhanced Collaboration: With SOLIDWORKS PDM, you don’t need to email files back and forth. Instead, PDM acts as your central location, where you store all files that every user can access. You can send notifications automatically to alert users of a file’s status, set up replicated servers for your satellite offices, and view file status with a click.

Enhanced Collaboration

- Improved Data Security: The file history in SOLIDWORKS PDM is about more than just your engineering team. It also means you have a complete audit trail if any issues arise down the line. Additionally, you have full control over who can access what files, and at what stage in their lifecycle. For example, you can remove write access to any files that are listed as “approved”. Similarly, if you don’t want some users to have access to a set of files, you can ensure they don’t.

- Accelerated Design Reuse: When files are easier to find, that makes them easier to reuse. With SOLIDWORKS PDM, it’s easy to grab an existing file and reuse it for a new design. This cuts down on rework and lets your team focus on designing something brand new.

- Seamless Hand-off to Manufacturing: The workflows in SOLIDWORKS PDM, combined with variable access levels, make the hand-off from design to manufacturing seamless. For instance, all you need to do is give manufacturing access to any files you’ve deemed as “Approved” or “In Manufacturing” via their lifecycle state. Then, your manufacturing team can receive a notification about a new design, and there’s no question whether they have the latest and greatest or not.

Seamless Hand-Off to Manufacturing

Investing in Your Engineering Future

Unmanaged versions are a significant burden on your design and engineering teams. But why should they be? A robust data management solution, like SOLIDWORKS PDM, makes it easier than ever to take control of your data and to get your entire department on the same page.

Are you ready to stop the version control chaos and unlock your team's full potential?

Contact us today and learn more about how SOLIDWORKS PDM can transform your design process.

Related Articles

The Real Costs of Poor Data Management

SOLIDWORKS PDM 2025 - What's New

SOLIDWORKS PDM vs 3DEXPERIENCE CLOUD PDM: Workflows, Licensing & More

About Nick Sweeney

Nick Sweeney is a Marketing Specialist with GoEngineer with a focus on software solutions. Nick graduated from The Ohio State University in 2018, completing internships with CATI (now GoEngineer) and DriveWorks Ltd. Before joining the Marketing team, Nick spent 3 years in pre-sales with CATI, giving product demonstrations, leading technical discussions, and creating technical content.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.