SWOOD CAM

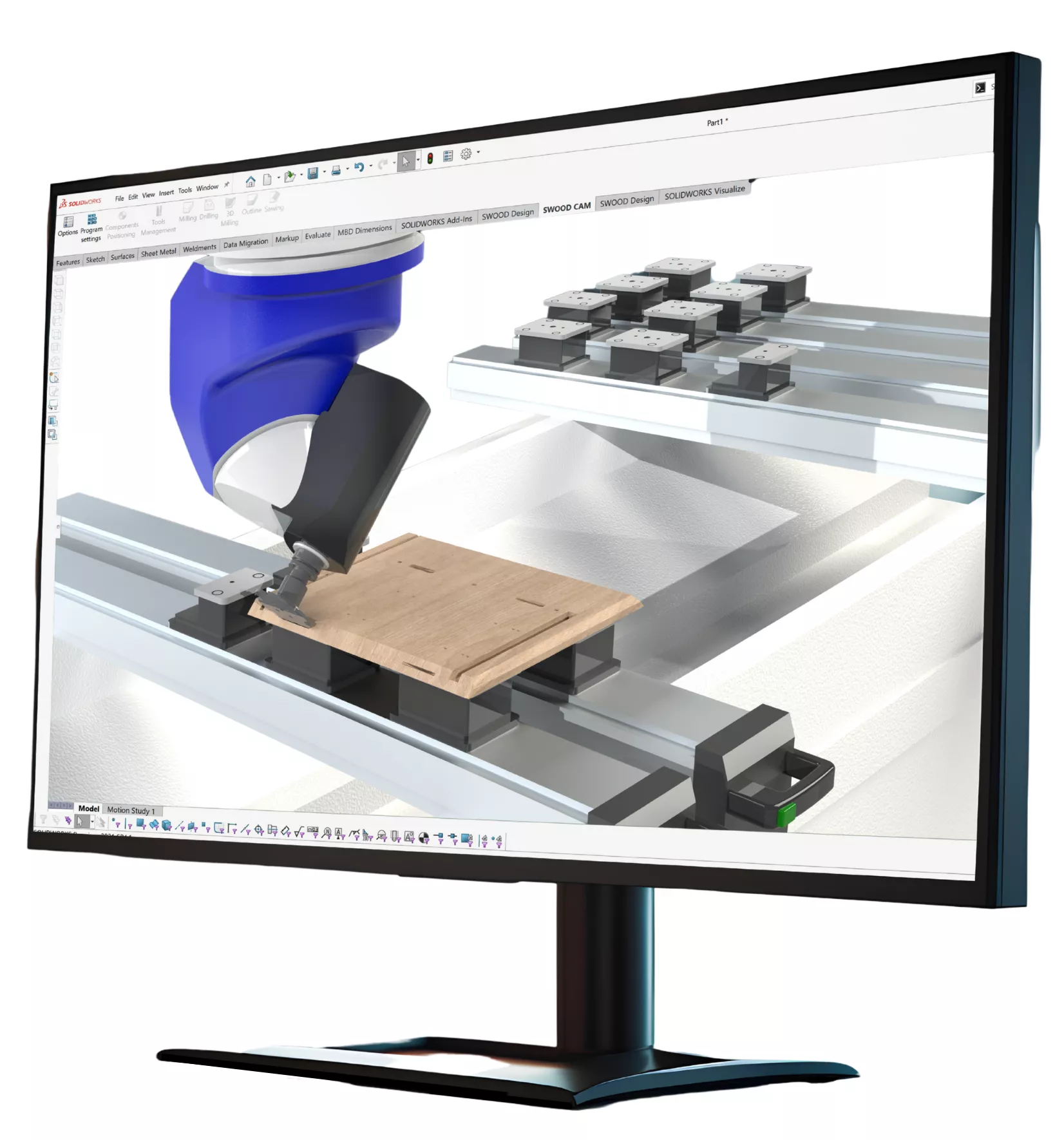

CNC Machining for Woodworking in SOLIDWORKS

What is SWOOD CAM?

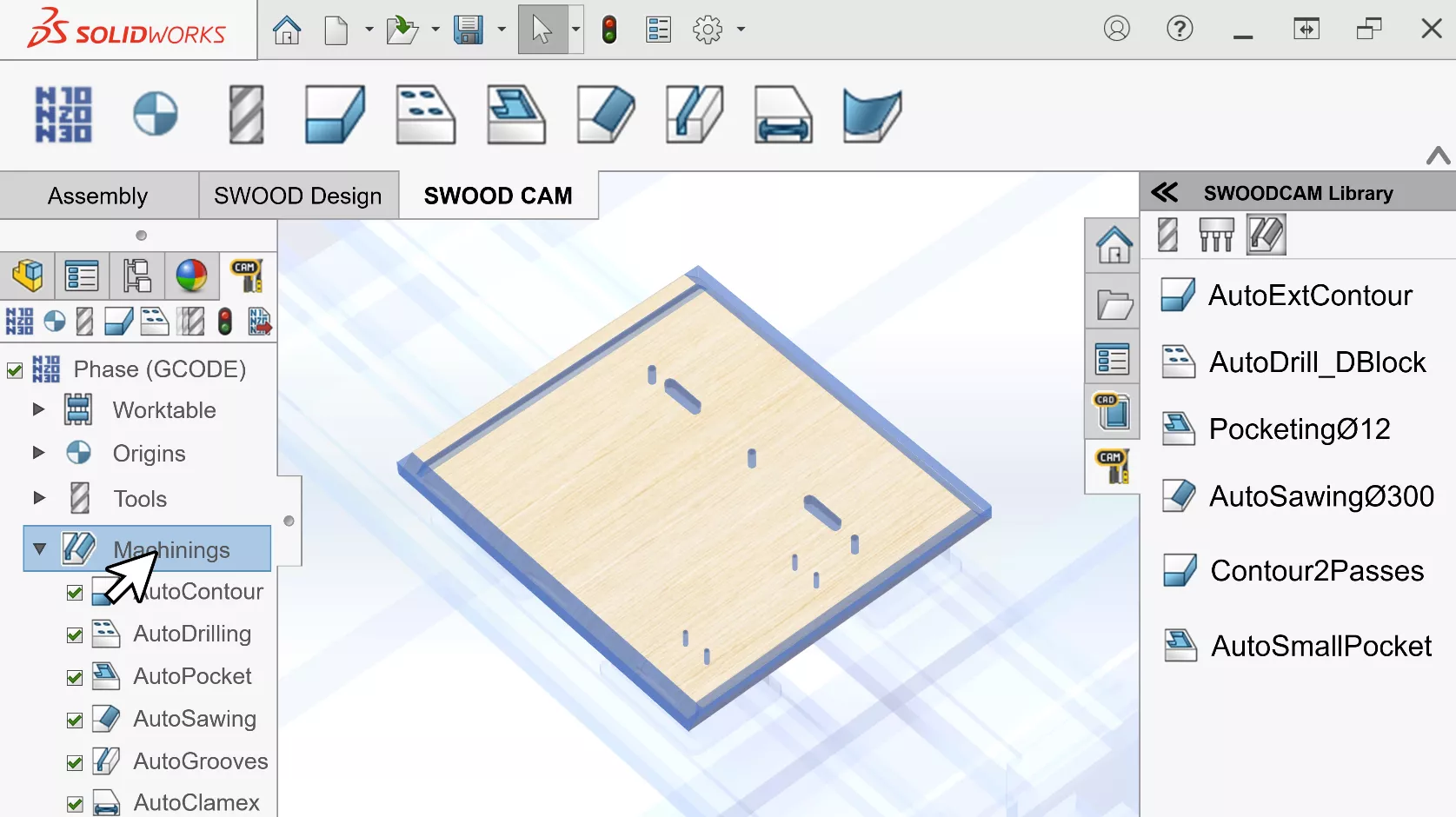

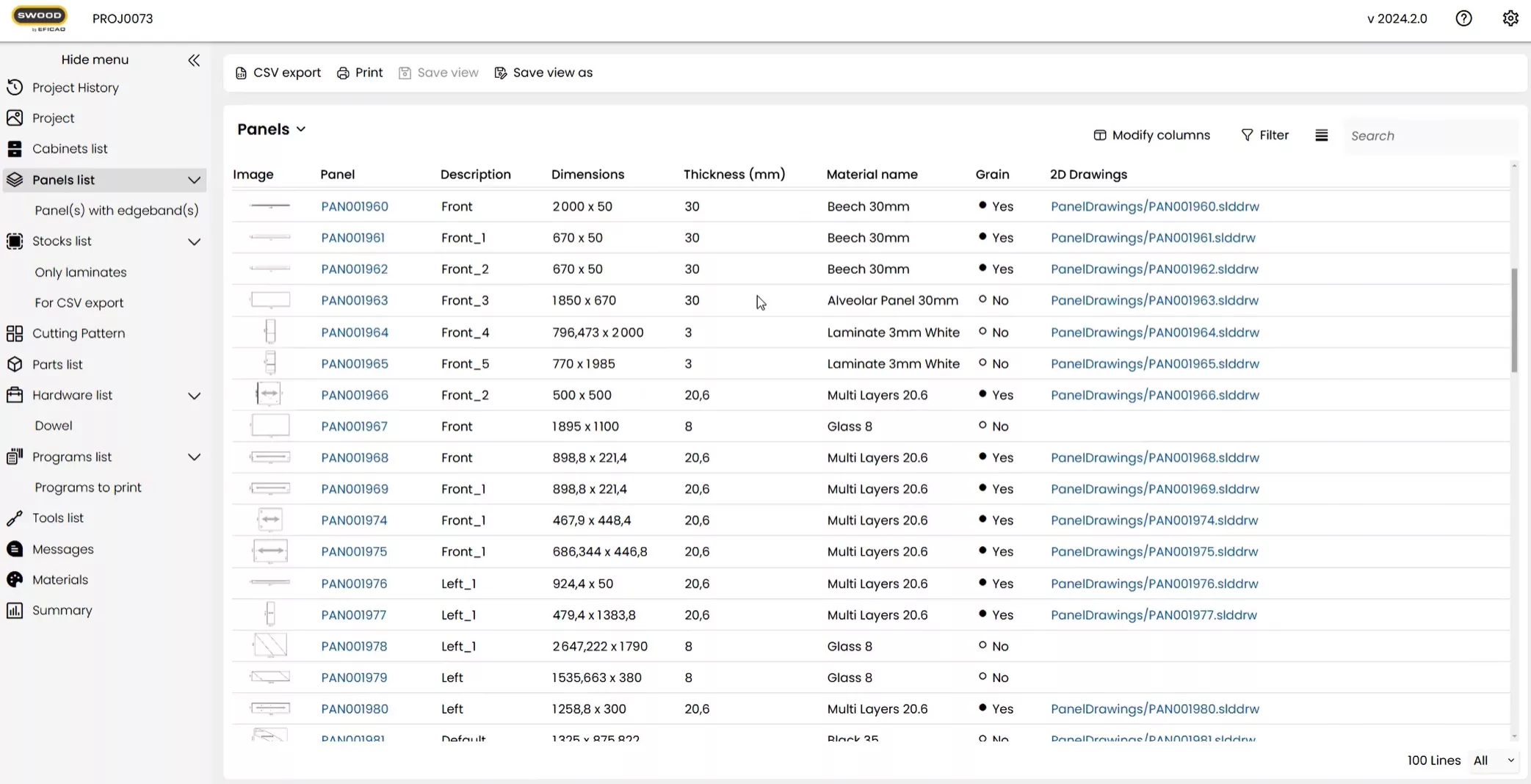

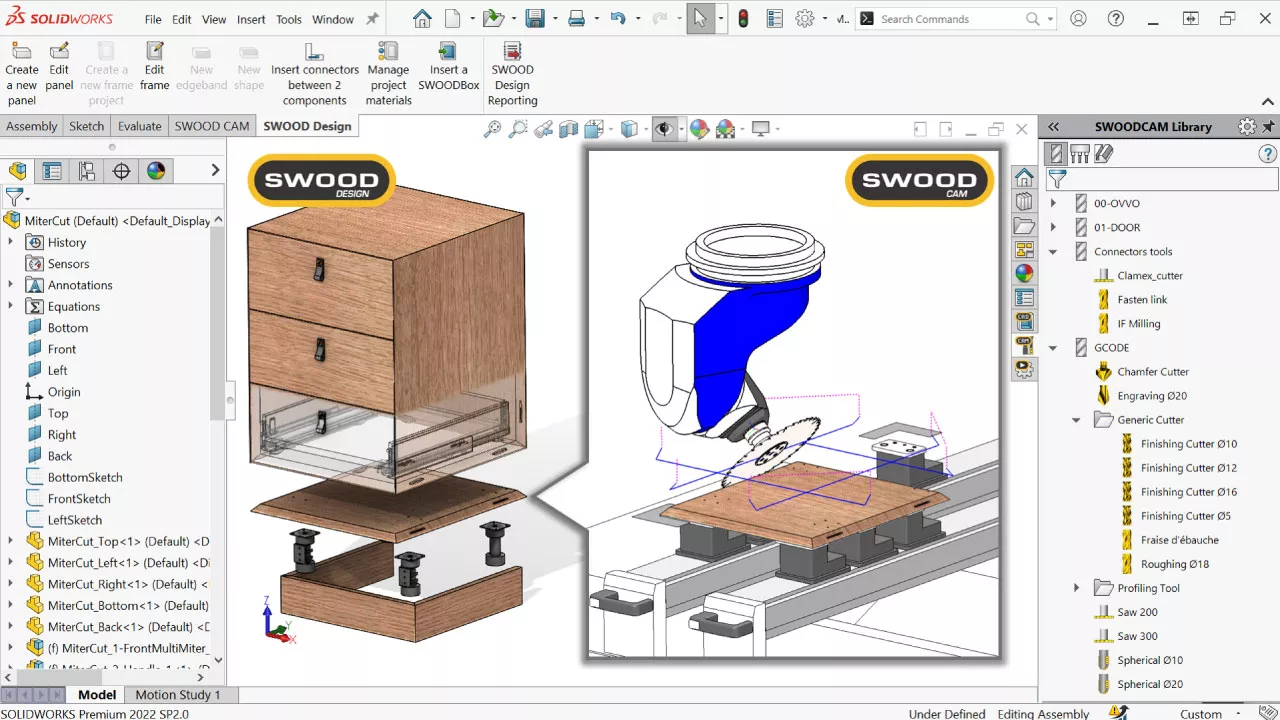

SWOOD CAM is a woodworking-focused CAM solution that works directly inside SOLIDWORKS. It helps automate the creation of CNC programs for common machining operations like drilling, routing, nesting, and pocketing. Designed with woodworking in mind, it takes into account material details such as grain direction, edge banding, and composite panels to optimize toolpaths for both materials and machines. With an easy-to-use, visual interface, users can assign tools, simulate machining steps, and export G-code for a wide variety of CNC machines. SWOOD CAM also integrates smoothly with SWOOD Design, making it easy to move from design to production in one connected workflow.

Tools

Woodworking-Specific Machining Operations

SWOOD CAM goes beyond generic CAM software by offering specialized operations for woodworking, including dowel insertion, mortise and tenon joints, and hinge or fitting pocketing. These tailored features ensure toolpaths accurately match real-world woodworking methods and production requirements.

Material and Grain Direction Awareness

By factoring in grain direction and panel structure, SWOOD CAM ensures that maching strategies align with both the visual and structural needs of wood components. This is essential for furniture manufacturers who prioritize appearance and durability, especially when working with decorative materials.

Tool and Machine Configuration

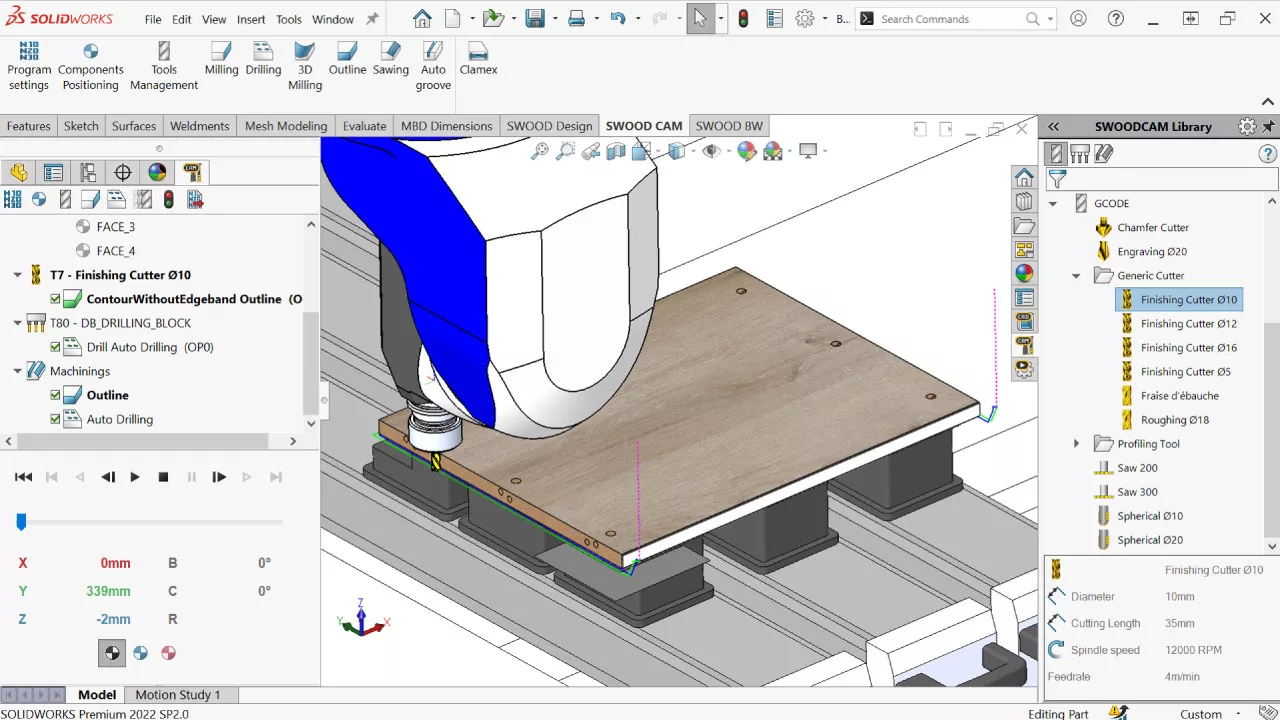

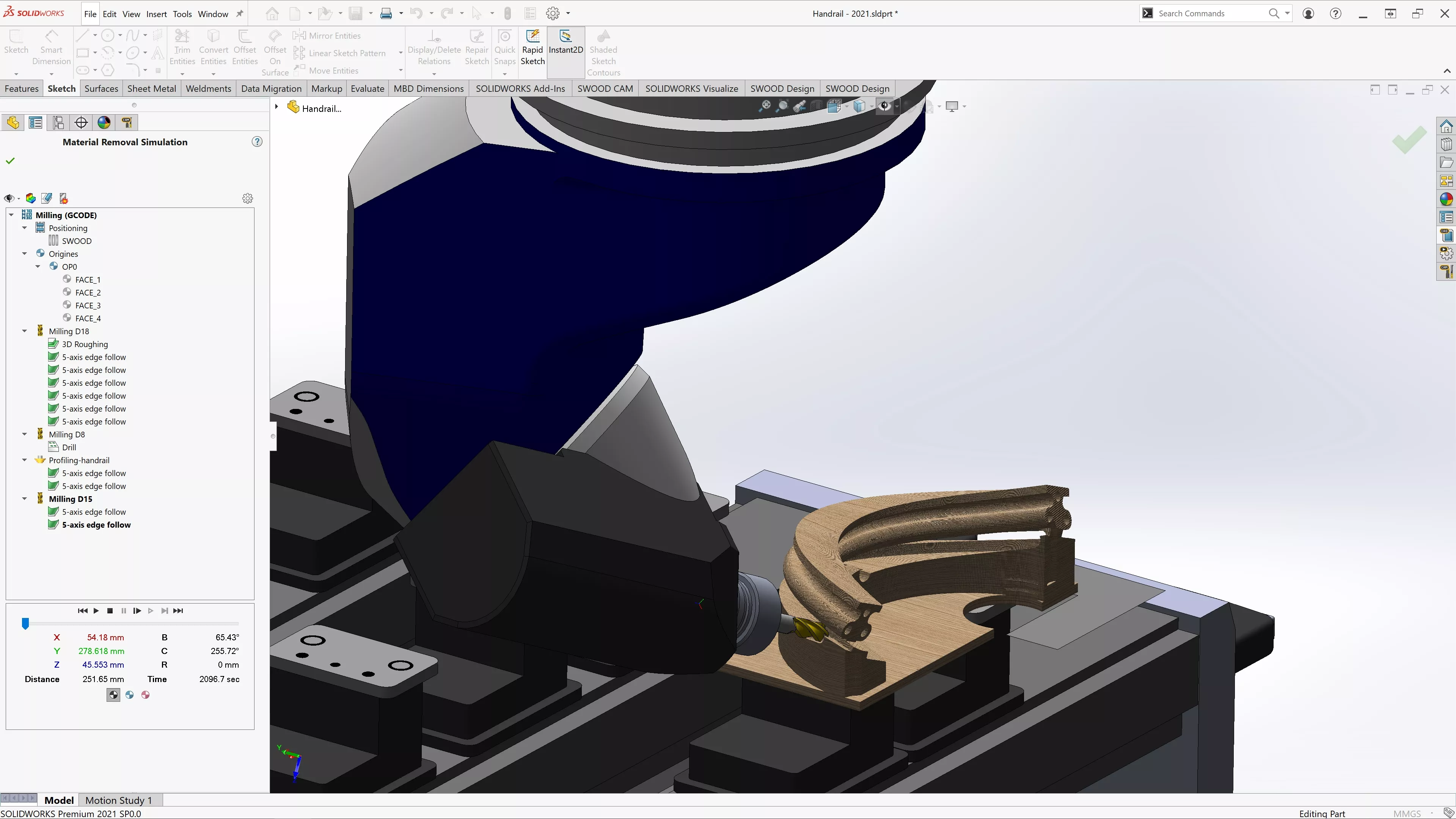

With customizable machine and tool settings, SWOOD CAM allows you to define cutting parameters, tool dimensions, spindle speeds, and more. This ensures accuracte CNC simulations and outputs that align with your workshop's specific equipment and machining requirements.

Post-Processing and G-Code Generation

SWOOD CAM supports a wide variety of CNC machines by using customizable post-processors to generate accurate, machine-ready G-code. Whether working with point-to-point CNC machines or nesting routers, SWOOD CAM ensures full compatibility and reliable performance across your woodworking production workflow.

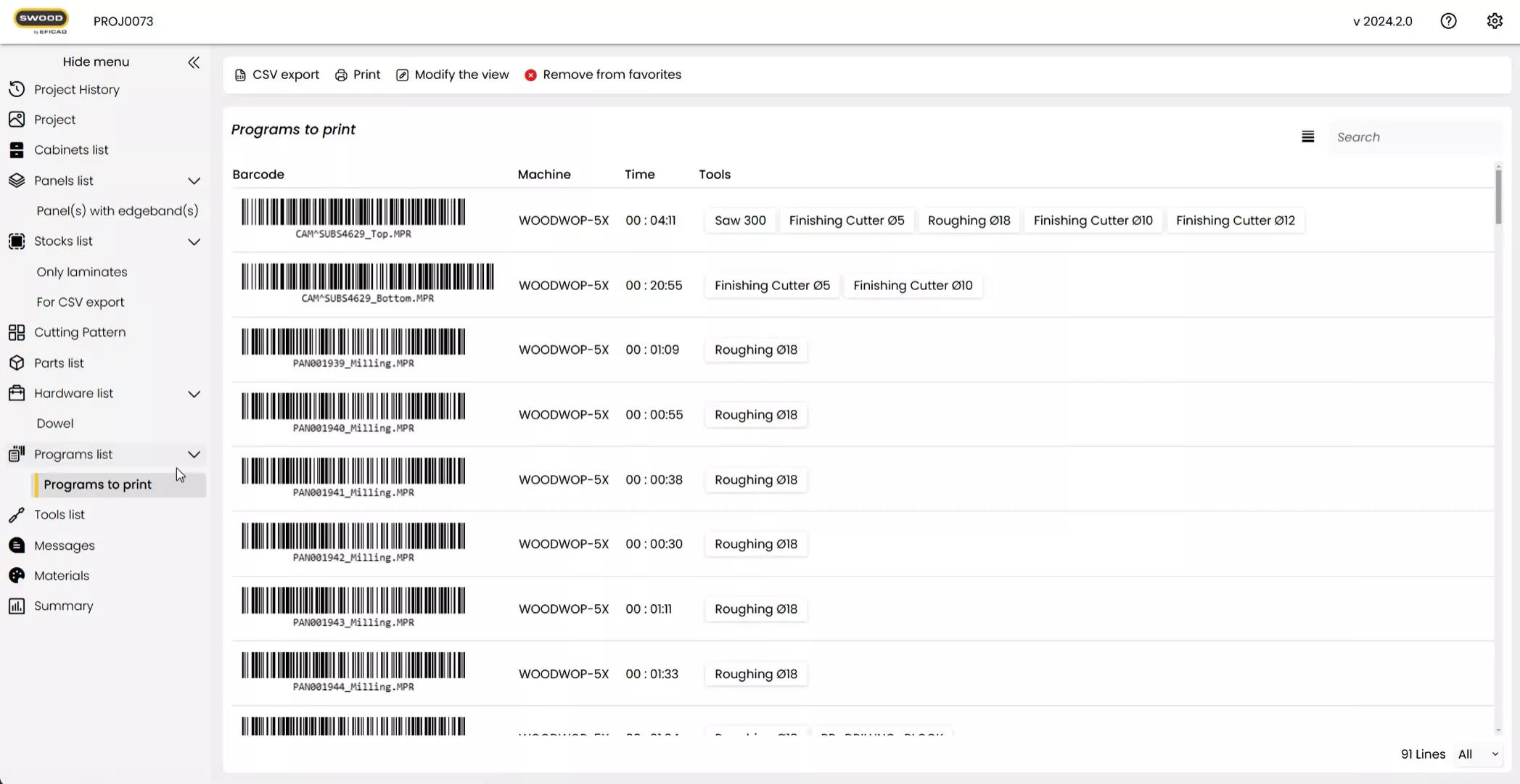

Automatic Documentation and Reports

To streamline woodworking production, SWOOD CAM produces comprehensive machining reports, tool lists, and job sheets. These outputs help bridge the gap between design and the shop floor, ensuring clear communication and accurate execution of CNC operations.

Frequently Asked Questions

SWOOD CAM supports a wide range of CNC machines, including 3-axis up to 5-axis machines commonly used in the woodworking industry. Post-processors are customizable to match different machine brands like Biesse, Homag, SCM, and more.

Yes. SWOOD CAM supports rule-based machining strategies that can automatically apply specific operations based on the type of geometry or material. This significantly reduces setup time for repeated production runs.

Absolutely. Users can set up custom tool libraries with parameters like tool diameter, spindle speed, and feed rates. Machine configurations can also be saved and reused, ensuring consistency across jobs and compatibility with your equipment.

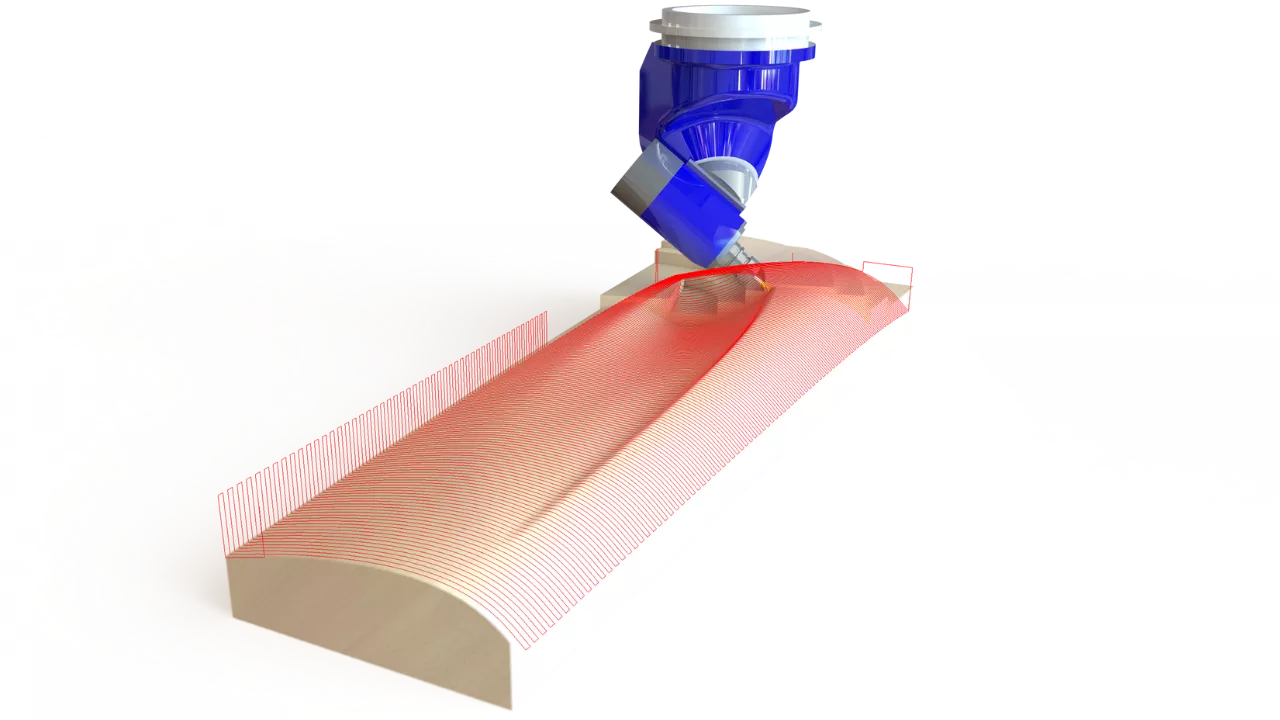

Yes. SWOOD CAM includes full 3D machining simulation, allowing users to visualize the cutting process, verify toolpaths, and identify any collisions or errors before sending the code to CNC machines.

Yes. After setting up your toolpaths, SWOOD CAM uses a post-processor to generate machine-ready G-code. This code can be sent directly to CNC equipment or exported as needed.

Nesting is not built directly into SWOOD CAM but is available through SWOOD Nesting, a complementary module. When used together, SWOOD CAM can import optimized layouts from SWOOD Nesting and assign appropriate machining operations.

SWOOD CAM Features

CNC Toolpath Generation

SWOOD CAM automates the creation of CNC toolpaths directly from 3D furniture and cabinet models in SOLIDWORKS. It intelligently detects features such as holes, grooves, pockets, and contours, and applies the correct machining operations based on predefined rules. This significantly reduces manual programming time, lowers the risk of errors, and speeds up the transition from design to CNC machining in woodworking production.

3D Toolpath Simulation

SWOOD CAM provides realistic, visual simulations of CNC machining operations, giving users a detailed preview of how material will be cut directly from their SOLIDWORKS models. This advanced simulation helps detect potential collisions, verify toolpaths, and confirm machining strategies before sending code to the CNC machine, reducing errors, material waste, and production delays.

Seamless Integration with SWOOD Design

SWOOD CAM integrates seamlessly with SWOOD Design, allowing you to carry over all parametric features, material selectrions, and hardware configurations directly from your 3D models into the CNC programming process. This tight integration ensures consistency between design and manufacturing, eliminates repetitive data entry, and significantly improves efficiency across your woodworking production workflow.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services