SWOOD Center

Centralized data management for woodworking projects

What is SWOOD Center?

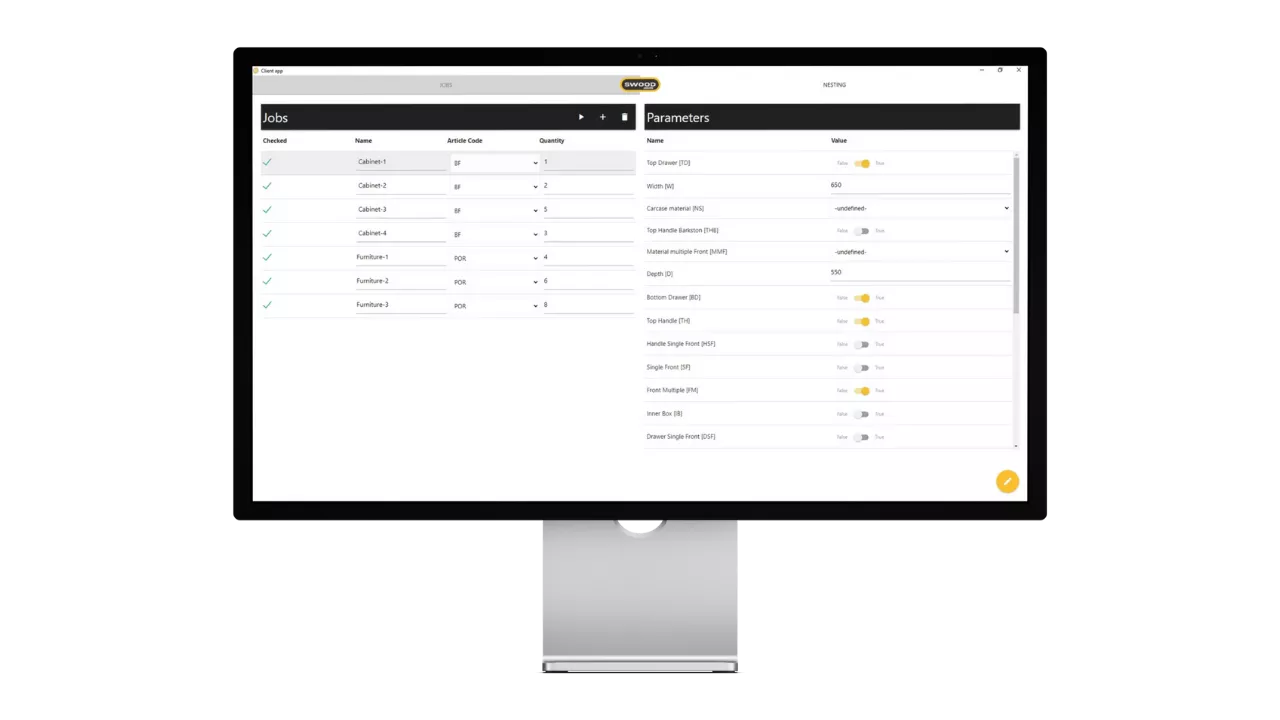

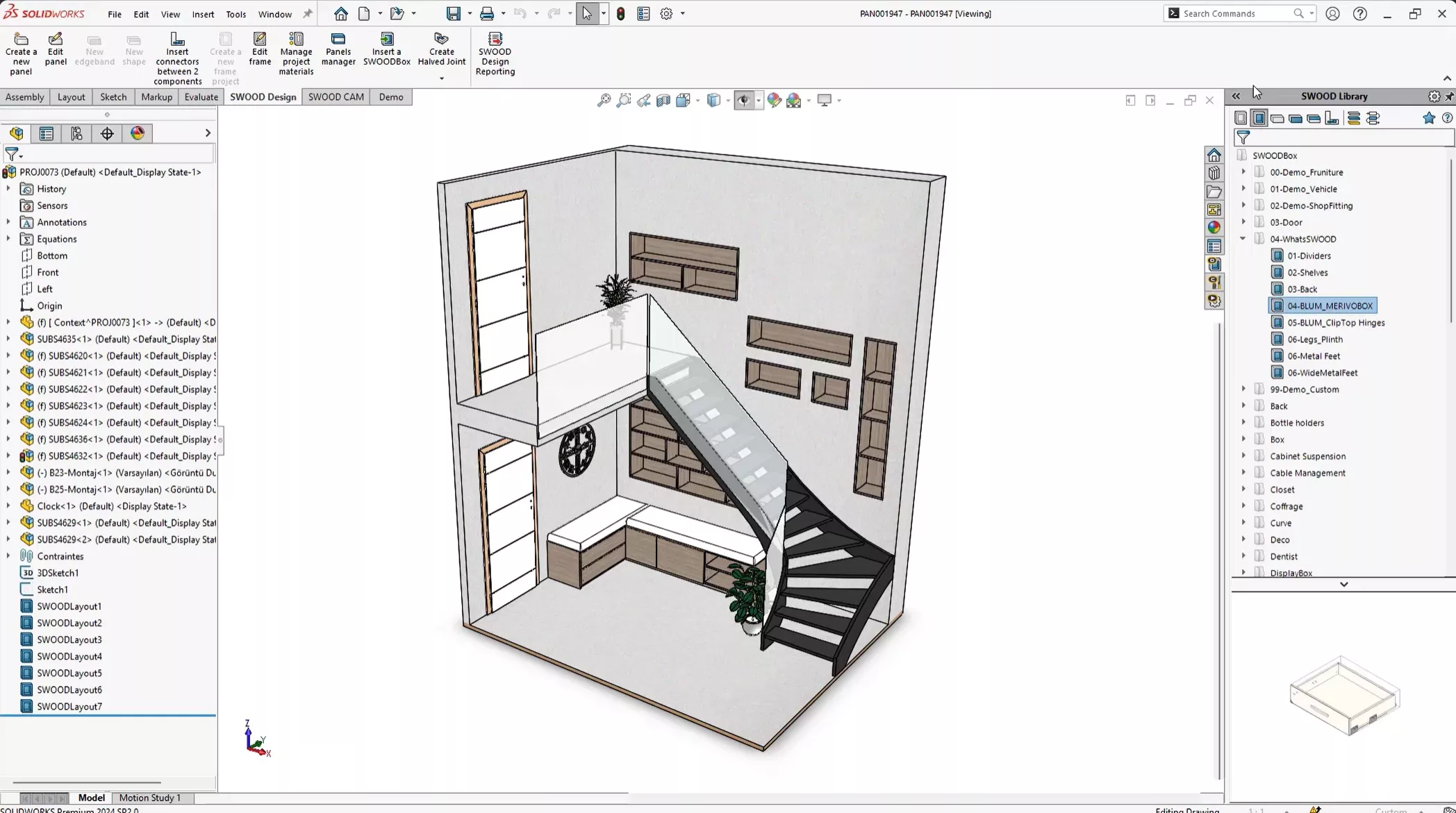

SWOOD Center is a central hub that helps woodworking teams using SOLIDWORKS to manage all their manufacturing data in one place. It works seamlessly with SWOOD Design and SWOOD CAM, making it easier to keep materials, panels, edge banding, and hardware organized and consistent across projects. By connecting to your external data systems, SWOOD Center lets users standardize resources, simplify library updates, and reduce errors. Whether you're part of a small workshop or a large manufacturing team, SWOOD Center helps streamline workflows and keep everyone on the same page.

Tools

Multi-User Collaboration

In collaborative woodworking environments, SWOOD Center ensures that teams can work from a unified data souce. Multiple users can access and manage shared materials, hardware, and design standards simultaneously, helping maintain consistency, reduce errors, and streamline workflows across the entire manufacturing process.

Access Control and Permissions

SWOOD Center offers customizable user roles and permission settings, allowing administrators to manage who can access, modify, or delete shared woodworking resources. This role-based access control enhances data security, supports governance policies, and ensures only authorized team members make critical changes.

Custom Configuration Templates

With SWOOD Center, manufacturers can create and apply custom configuration templates tailored to various project types. These templates streamline setup for new designs or production runs, ensuring consistency with predefined woodworking standards, materials, and methods across every job.

Multi-Site Deployment Support

SWOOD Center supports multi-site deployment, making it easy for woodworking companies with multiple locations to maintain consistent data across all branches. Centralized updates to materials, components, and configurations ensure standardization and efficiency throughout every production facility.

Frequently Asked Questions

SWOOD Center ensures consistency across projects, streamlines updates to manufacturing data, improves collaboration between teams, and reduces errors by providing a single source of truth for all SWOOD-related resources.

SWOOD Center is ideal for woodworking companies of all sizes - from small workshops to large manufacturers - especially those managing multiple users, projects, or production sites.

Yes. SWOOD Center supports multi-user access, allowing teams to collaborate in real time while maintaining data integrity and version control.

Yes, administrators can assign roles and permissions to users, ensuring that only authorized personnel can edit, add, or delete data.

Users can manage a wide range of data, including panels, laminates, edge banding, hardware, connectors, tooling, and machining rules. It also supports custom configuration templates for different production scenarios.

SWOOD Center can operate within a local network or cloud-based environment, depending on the user's company IT infrastructure. Internet access may be required for remote or multi-site setups.

SWOOD Center Features

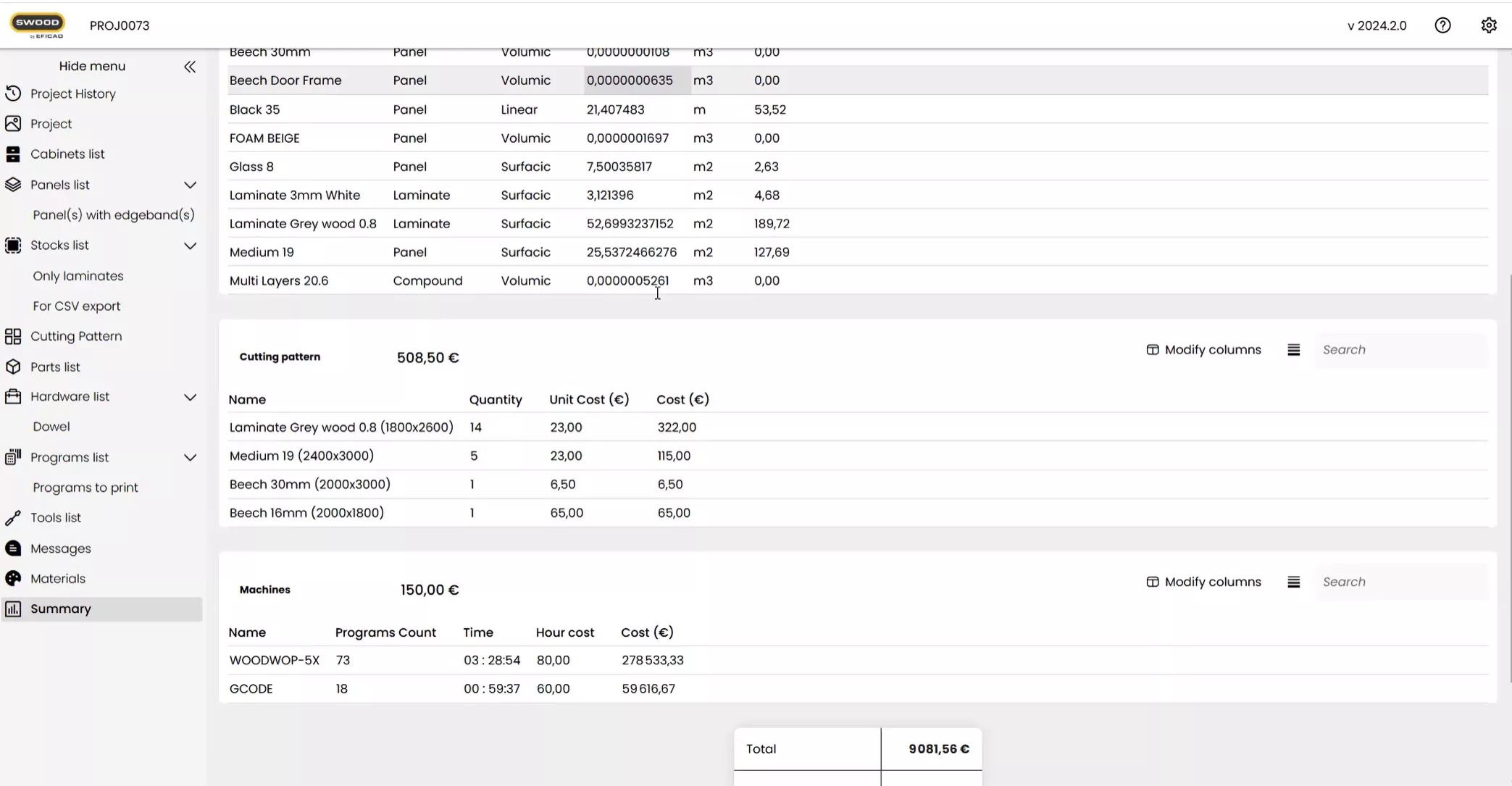

Centralized Resource Management

SWOOD Center brings together all critical woodworking data, such as materials, panels, edge banding, hardware, and connectors, from your third-party systems into one centralized platform. By managing this data in a single location, it ensures consistency across design and manufacturing workflows, reduces errors, and simplifies updates across teams, projects, and workstations. This streamlined data management enhances collaboration and supports scalable production.

Automatic Synchronization With SWOOD Design & CAM

By connecting directly with SWOOD Design and SWOOD CAM, SWOOD Center keeps all your woodworking data in sync. Any updates to materials, hardware, or panel configurations are automatically reflected throughout the design and machining processes, helping teams work more accurately, efficiently, and without redundancy.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services