SWOOD Design

Advanced cabinet and furniture modeling in SOLIDWORKS

What is SWOOD Design?

SWOOD Design is a powerful add-in for SOLIDWORKS that makes it easier to design custom furniture and wood-based assemblies. Built with woodworking professionals in mind, it uses a parametric, drag-and-drop approach to help users create cabinets, panels, connectors, and hardware, faster and with fewer errors. SWOOD Design takes care of details like material management, grain direction, and edge banding. It also automatically generates everything needed for production, including BOMs, cut lists, and CNC data. Fully integrated with SOLIDWORKS and part of the larger SWOOD suite, it helps streamline workflows from design to manufacturing.

Tools

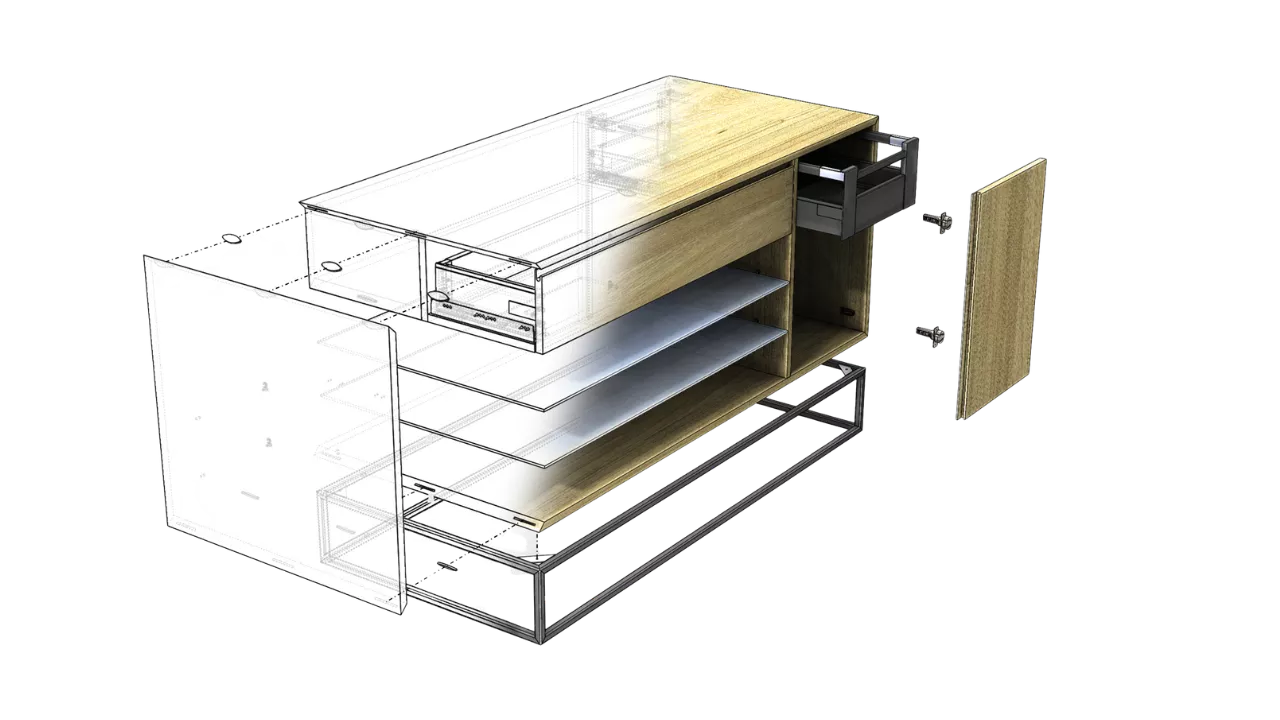

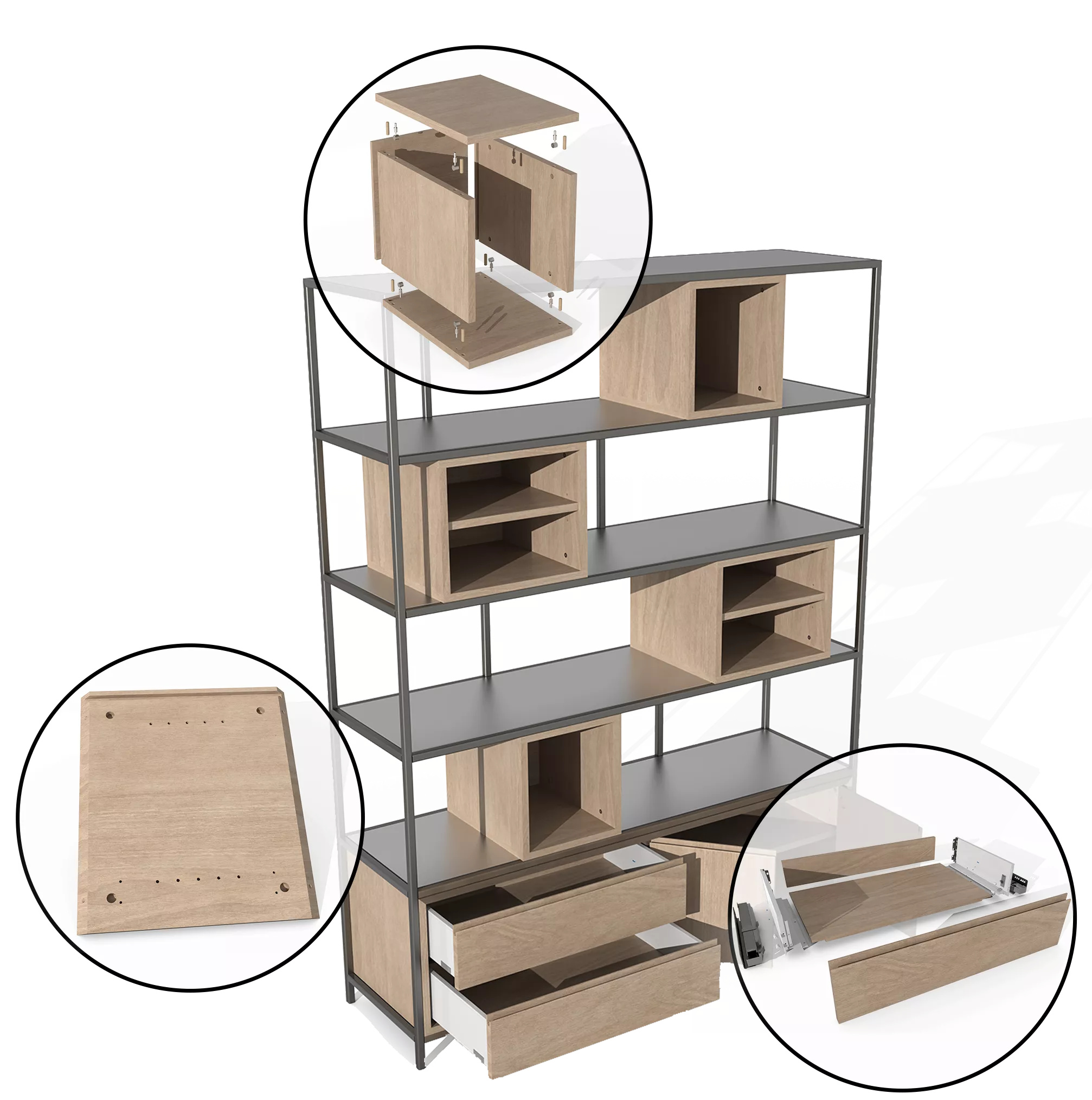

Drag-And-drop component insertion

Easily add panels, doors, drawers, hardware, and accessories to your 3D furniture models using customizable component libraries. Insert predefined elements directly into your SOLIDWORKS design to speed up modeling and maintain consistency across projects.

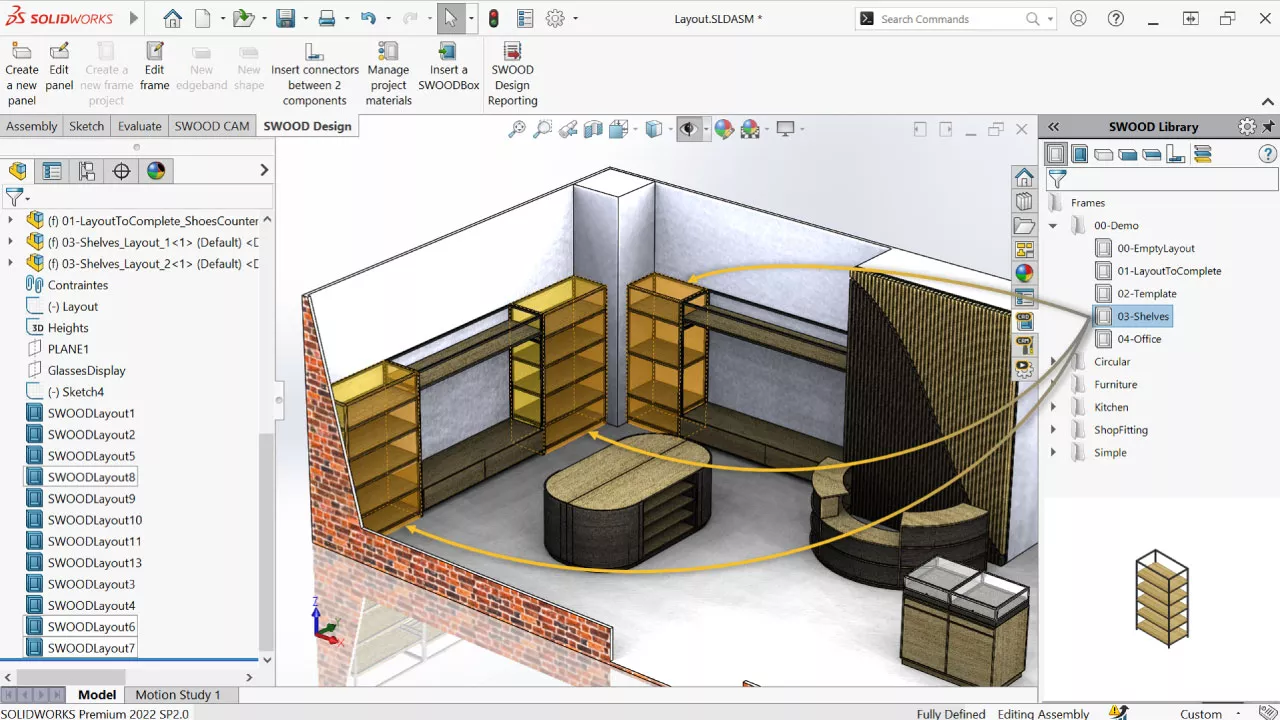

SWOODBox Library system

Store reusable components like frames, boxes, and fittings as smart, configurable templates. Quickly insert them into new designs with automatic adjustments based on project parameters. SWOODBox helps speed up design work and ensures consistency across all of your furniture projects in SOLIDWORKS.

edge banding tools

Automatically apply and manage edge treatments in your woodworking designs, including visual representation, material assignment, and manufacturing data. SWOOD Design ensures edge banding is accurately displayed and documented, helping maintain consistency from design through CNC production.

connector management

Detect contact surfaces in your woodworking designs and insert fasteners such as dowels, cams, and hinges using preconfigured rules for precise spacing and orientation. This feature in SWOOD Design streamlines assembly preparation, ensuring accurate placement and reducing manual adjustments during production.

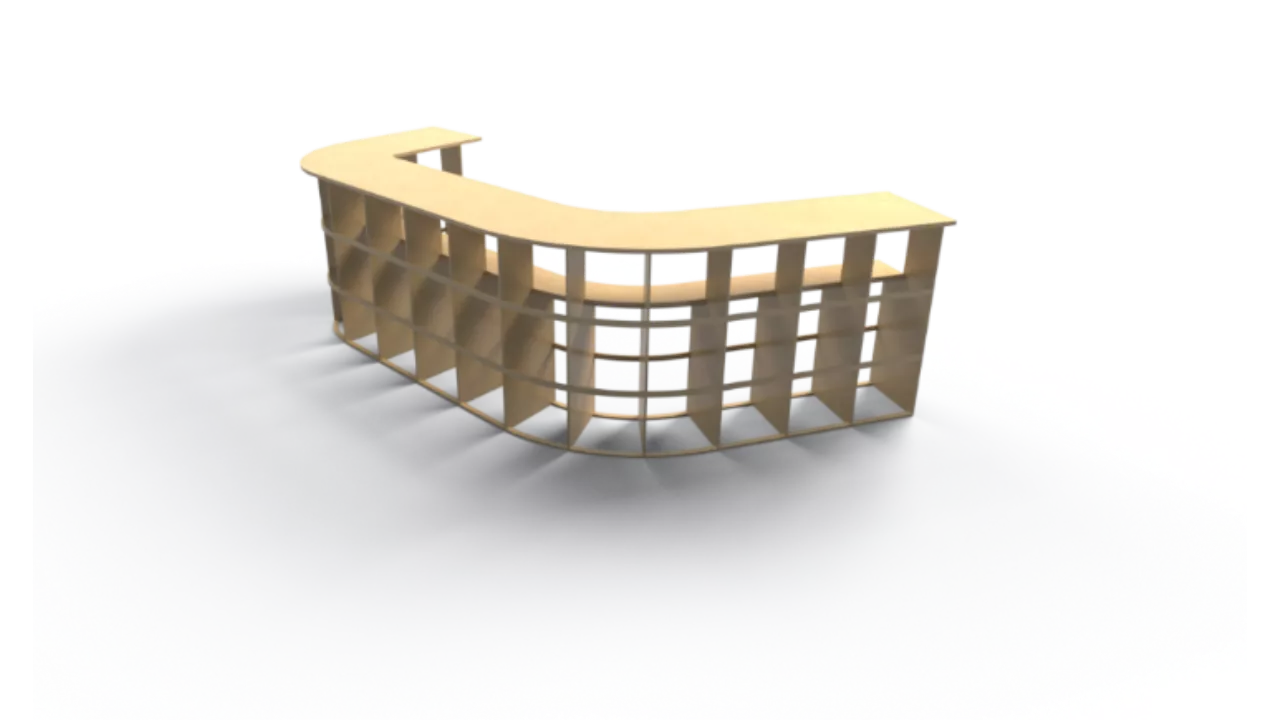

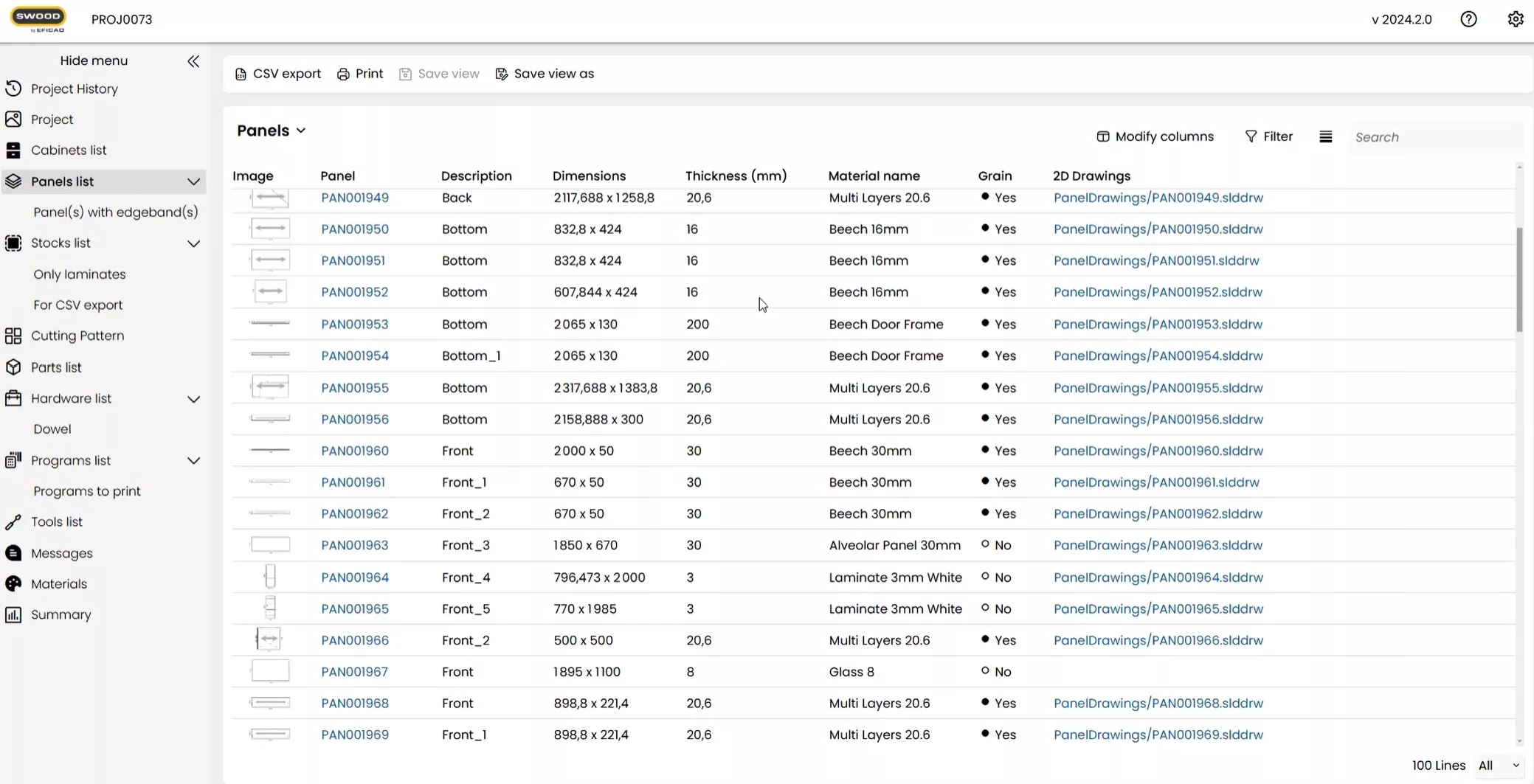

Panel and frame design tools

Create and design solid panels, curved components, multi-layer elements, and structural frames with precise control over their geometry and functional behaviour. SWOOD Design provides detailed tools that allow woodworking professionals to customize complex parts accurately, ensuring both design flexibility and manufacturability.

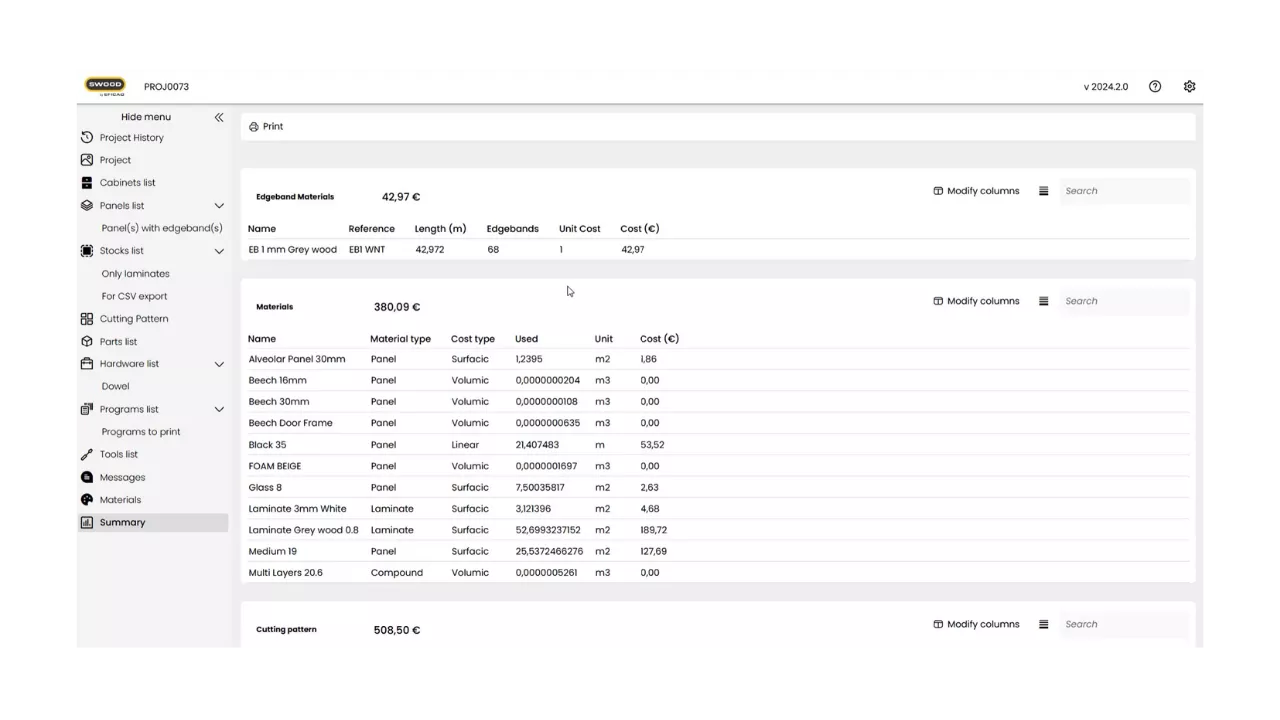

Bill of materials & cut list generation

Automatically generate precise Bill of Materials (BOMs), detailed cut lists, and comprehensive hardware summaries to streamline manufactring and purchasing processes. This feature ensures accuracy and efficiency by providing all essential documentation directly from your woodworking designs.

Report and label output

Easily export detailed reports in multiple formats includig PDF, Excel, CSV, or HTML to suit your documentation needs. Additionally, print custom part labels featuring barcodes or QR codes to enhance tracking and organization throughout your woodworking production process.

Frequently Asked Questions

SWOOD Design is a third-party add-in developed by EFICAD. It requires a valid SOLIDWORKS license to run.

Yes. Basic to intermediate knowledge of SOLIDWORKS is recommended, as SWOOD works within the SOLIDWORKS environment and relies on its core modeling functions.

Yes. You can import and define your own hardware and fittings, or use the built-in hardware libraries and rules to automate placement. The library installer that comes with SWOOD Design includes a large list of hardware from common brands in industry and are frequently being updated.

Yes. SWOOD Design allows you to create, customize, and manage your own material libraries, including wood types, laminates, edge banding, and core materials. You can define physical properties, textures, and machining behaviors for each material, ensuring accurate representation in both design and manufacturing processes.

Yes. SWOOD Design includes automated generation of BOMs, cut lists, and manufacturing reports directly from the 3D model.

Yes. SWOOD Design supports parametric modeling, allowing users to create flexible, customizable furniture designs that update automatically when dimensions or materials change.

SWOOD Design Features

parametric cabinet & furniture design

Design custom cabinets, shelves, and wood furniture faster with a fully configurable, rule-based system. SWOOD Design uses parametric modeling to automatically update all components when dimensions or features change, eliminating repetitive tasks and reducing errors. Whether you're creating single units or complex assemblies, this intelligent design approach streamlines your workflow and ensures consistency across every project. Perfect for woodworking professionals looking to speed up production and maintain design flexibility within SOLIDWORKS.

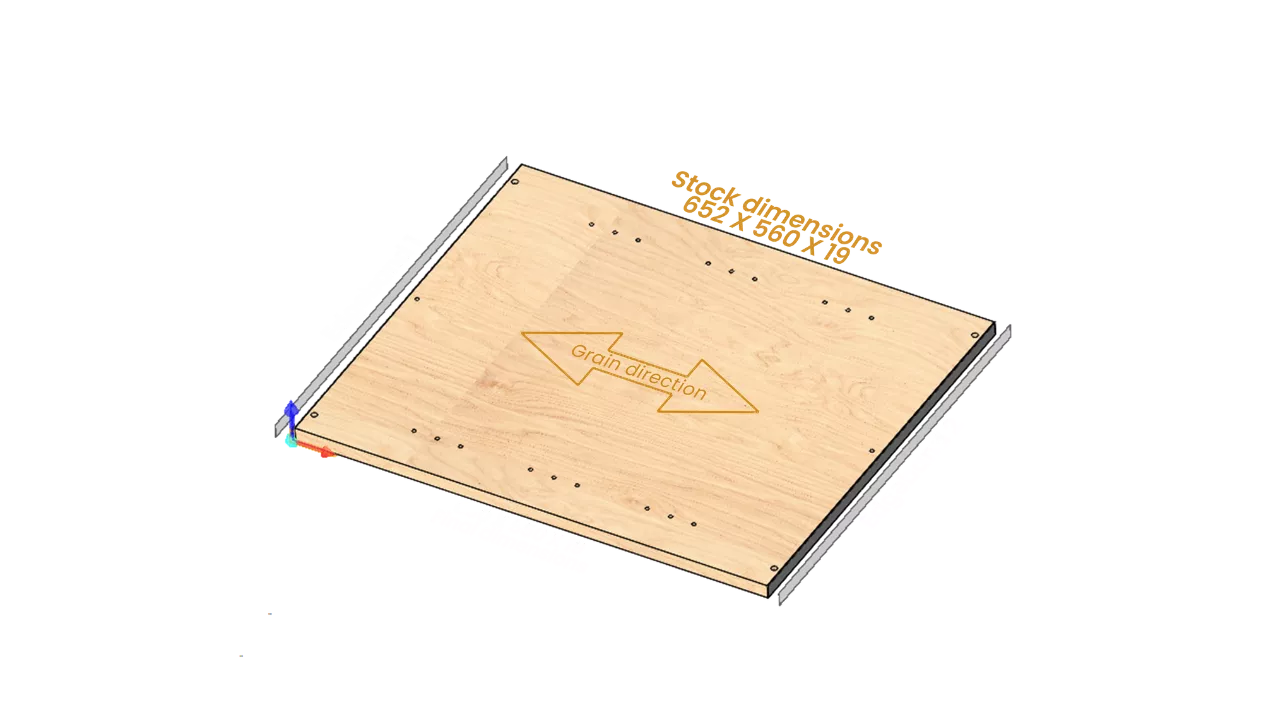

Material management

Easily assign and manage panel materials, grain direction, laminates, textures, and edge-banding within your furniture designs. SWOOD Design ensures that material properties are consistently applied across your projects, and when used with SWOOD CAM, it automatically adjusts CNC machining toolpaths based on these settings. This integration helps maintain material accuracy and improves the overall quality of your production process.

integration with swood cam (optional)

Prepare your woodworking models for CNC machining with seamless integration between SWOOD Design and SWOOD CAM. This connection allows you to automatically generate optimized toolpaths, define machining operations, and create CNC programs directly from your designs, streamlining the entire production workflow from design to manufacturing.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services