SWOOD Nesting

Smart sheet optimization for efficient CNC cutting

What is SWOOD Nesting?

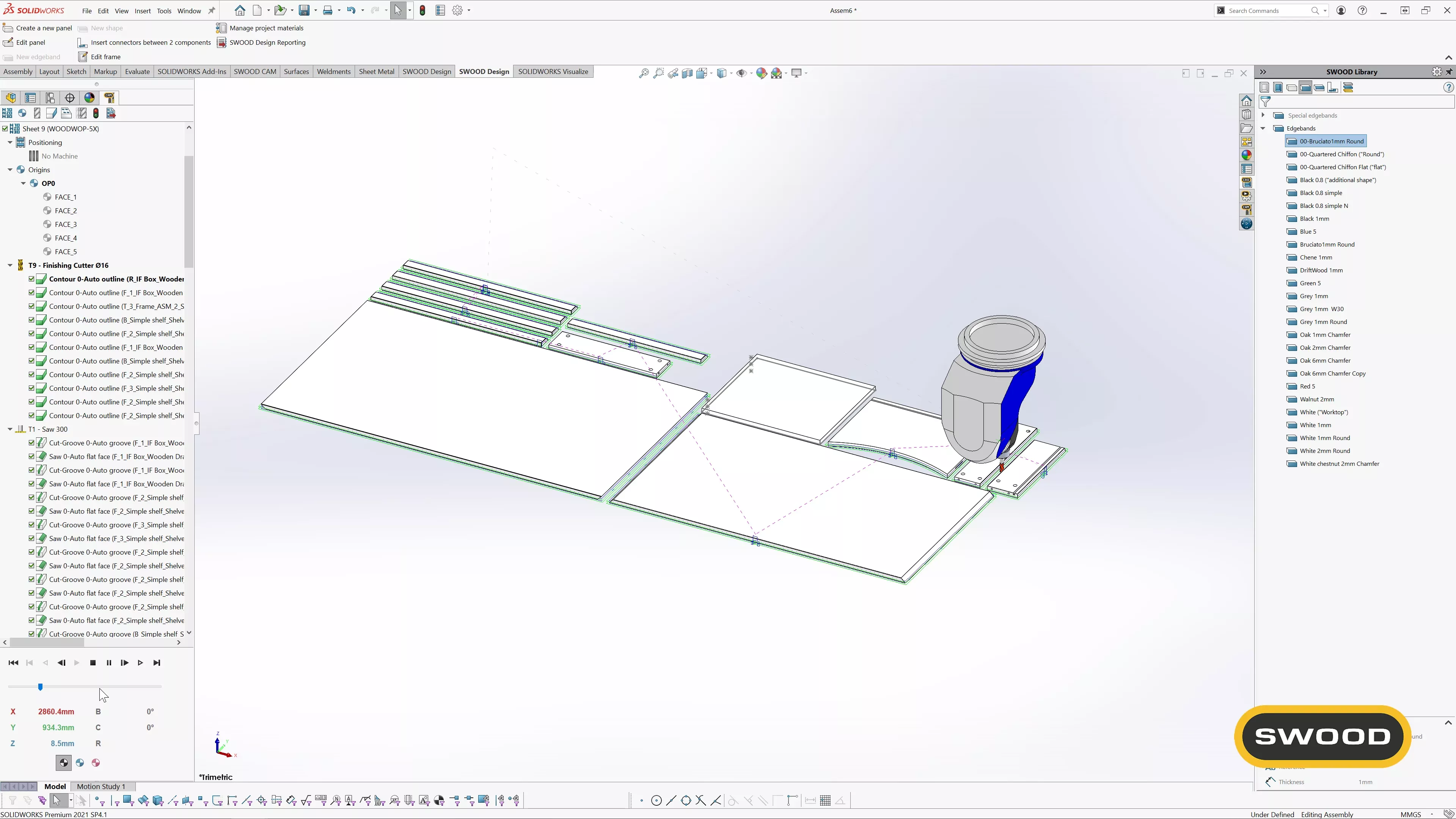

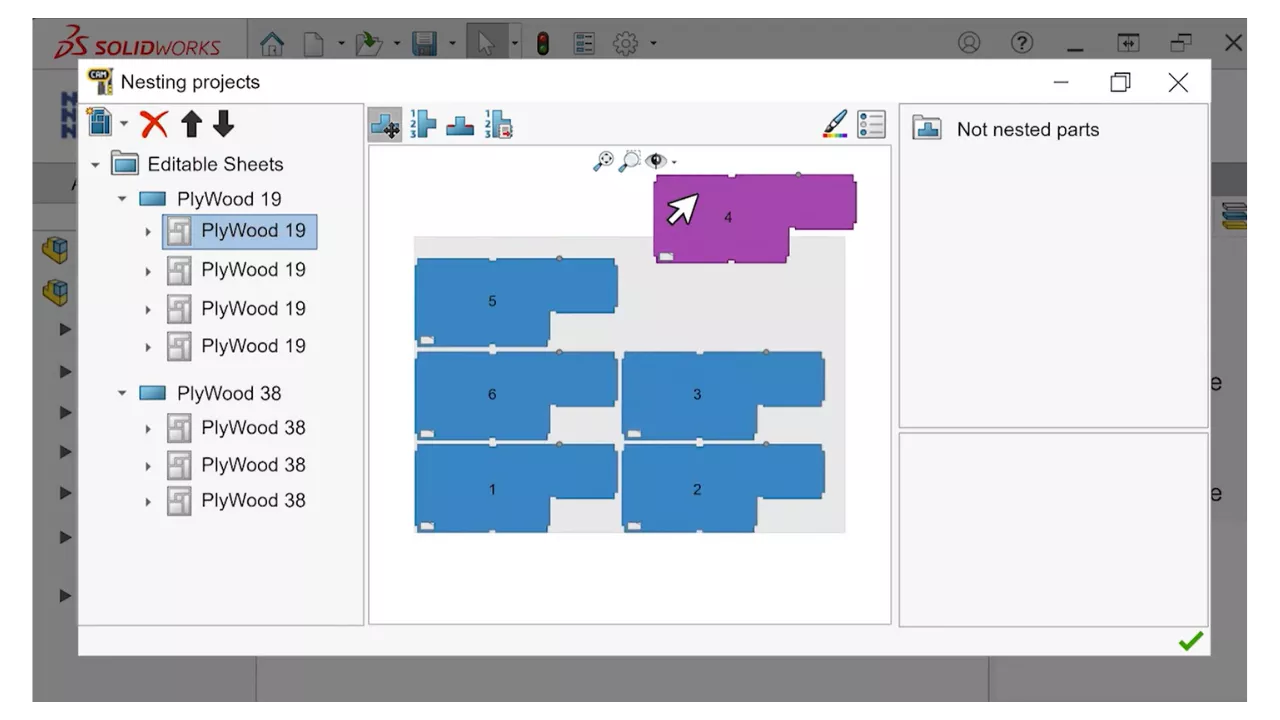

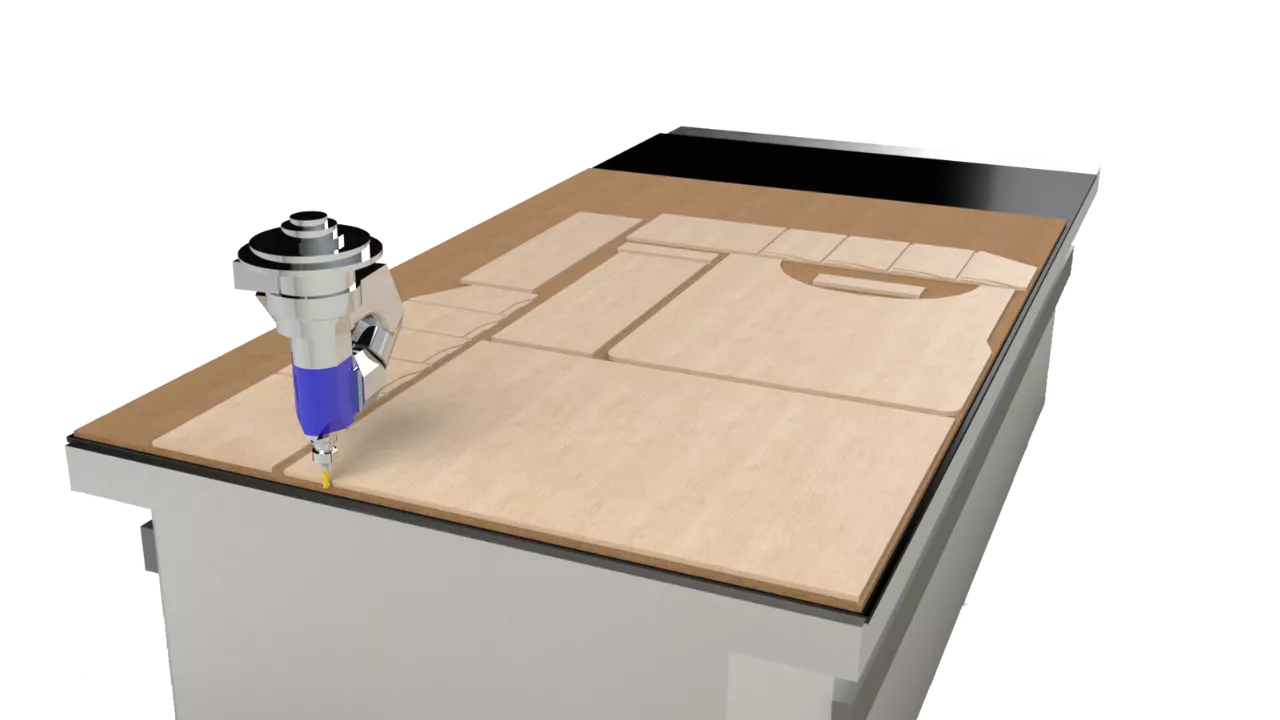

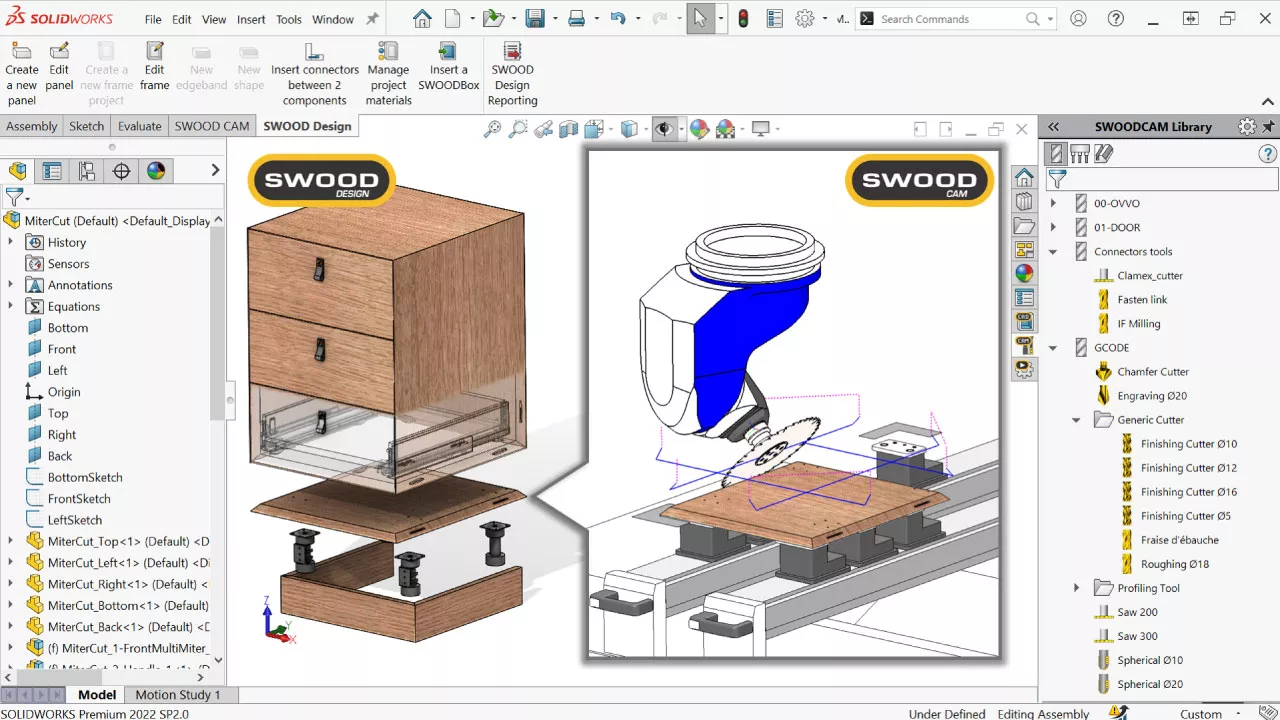

SWOOD Nesting is an advanced CNC nesting software solution built for woodworking professionals using SOLIDWORKS. It optimizes the placement of parts on sheet materials to minimize material waste and boost manufacturing efficiency. Fully integrated with SWOOD Design and SWOOD CAM, SWOOD Nesting automatically arranges both rectangular and irregular-shaped parts based on key parameters, such as grain direction, material type, and part margins. Ideal for batch processing and large-scale furniture production, it calculates the most efficient cutting layouts. Nesting results transfer directly to SWOOD CAM for toolpath creation, streamlining the entire workflow from design to CNC machining.

Tools

Grain Direction Control

SWOOD Nesting preserves grain direction settings from your SWOOD Design models, ensuring each part is accurately oriented on the sheet for visual and structural consistency. It maintains grain alignment while still optimizing sheet layout to reduce material waste and enhance CNC cutting efficiency.

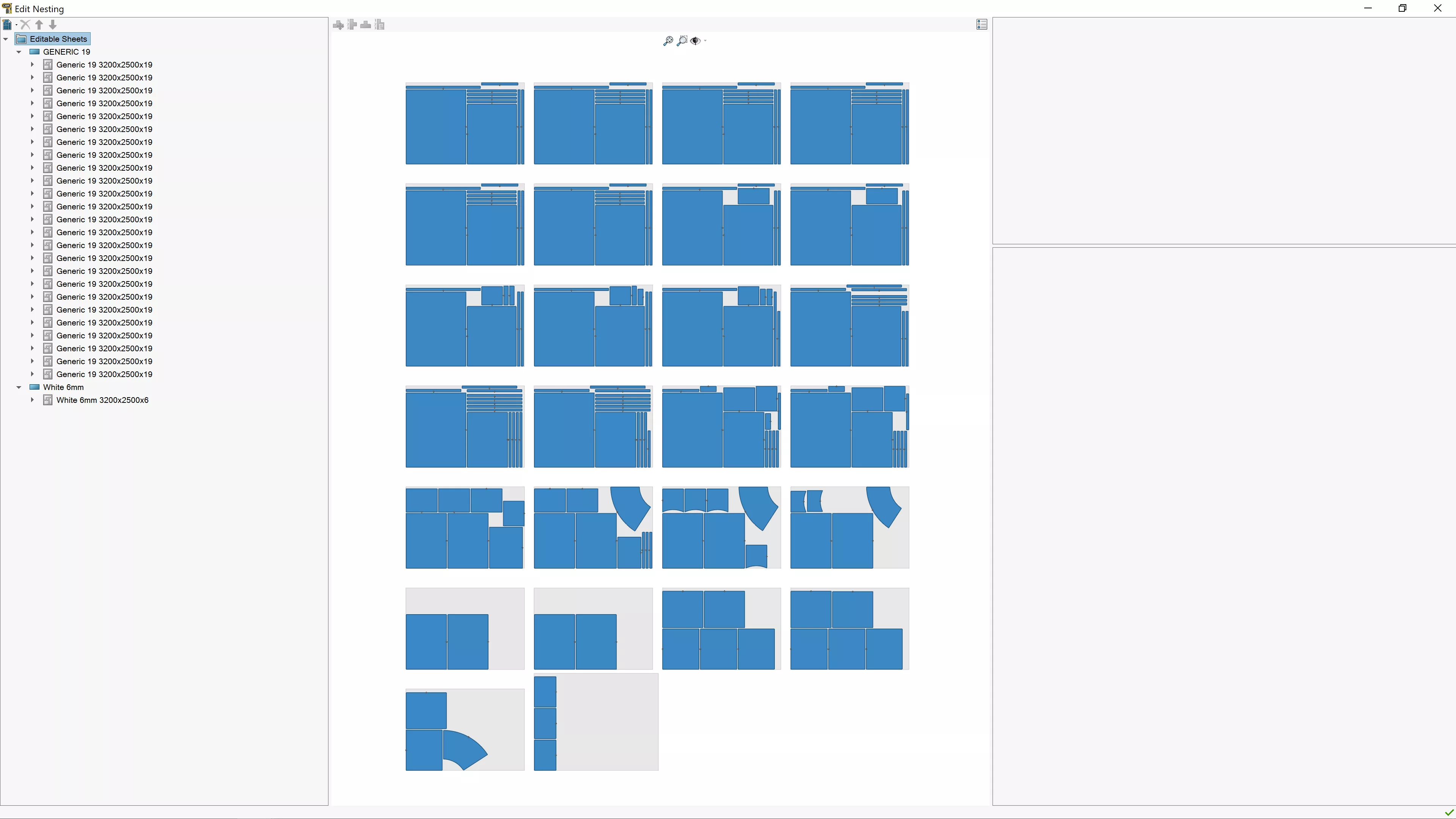

Multi-Sheet Optimization

For large or complex SOLIDWORKS assemblies, SWOOD Nesting efficiently arranges parts across multiple sheets when a single sheet isn't enough. It calculates the most effective layout based on material size, part geometry, and machining constraints, reducing waste and improving CNC workflow.

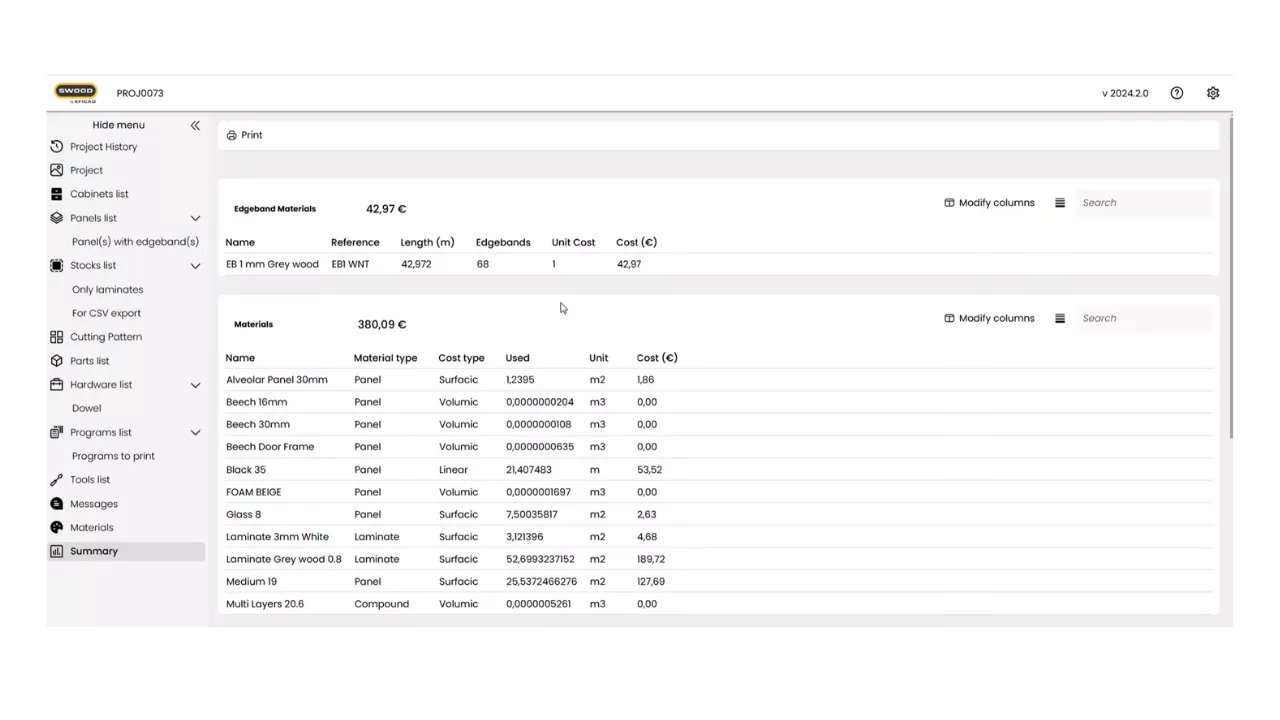

Material Management and Labeling

Effectively manage inventory with SWOOD Nesting, which tracks material types, thicknesses, and sheet quantities. The tool also creates part labels featuring barcodes or part numbers to streamline identification, sorting, and assembly during production.

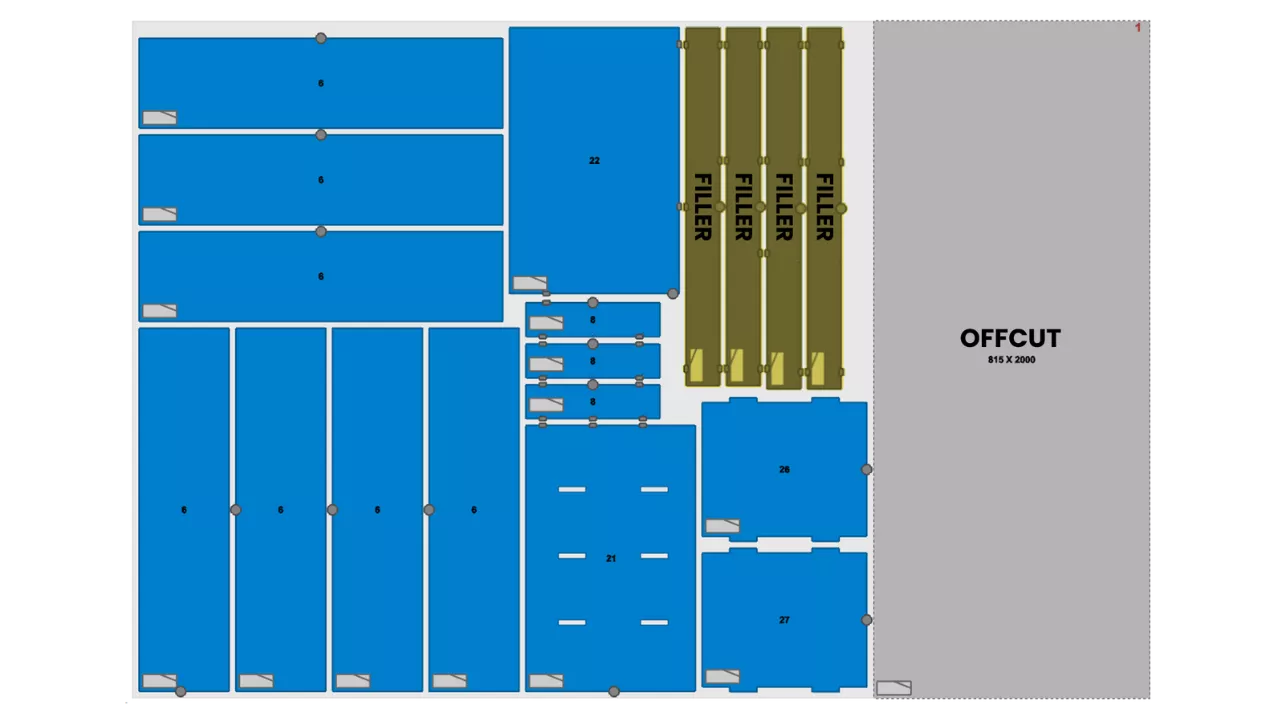

Offcut and Scrap Management

SWOOD Nesting keeps track of leftover sheet material and offcuts, making it easy to reuse partially used sheets in future projects. This not only helps reduce material waste but also improves inventory management by giving better visibility into available stock.

Nesting Rule Customization

With SWOOD Nesting, users can customize nesting rules and priorities, including part spacing, rotation limits, and margin settings, to suit specific manufacturing needs or visual requirements. This flexibility ensures the nesting layout aligns with workshop standards and production goals.

Manual Nesting Adjustments

When automation isn't enough, SWOOD Nesting lets you step in and fine-tune part layouts by hand. Users can easily reposition parts and rotate them to different sheets to meet specific production needs or aesthetic preferences.

Frequently Asked Questions

SWOOD Nesting automatically arranges parts on sheets using advanced nesting algorithms to minimize waste and maximize sheet utilization. Users can set grain direction, part spacing, and edge banding allowances.

Yes. Users can define grain direction per material and apply rotation rules to parts, including fixed or limited rotation (e.g., 90° increments).

Yes. SWOOD Nesting, through the integration with SWOOD Design, accounts for edge banding allowances, adjusting part sizes and nesting layout accordingly.

Yes. SWOOD generates customizable reports showing sheet usage, part counts, offcuts, and machining time.

Yes. SWOOD Nesting can generate part labels with barcodes, part names, material info, and other metadata for sorting and assembly.

Yes. Users can nest multiple jobs at once or nest assemblies with multiple material types and panel thicknesses.

SWOOD Nesting Features

Automatic Part Nesting

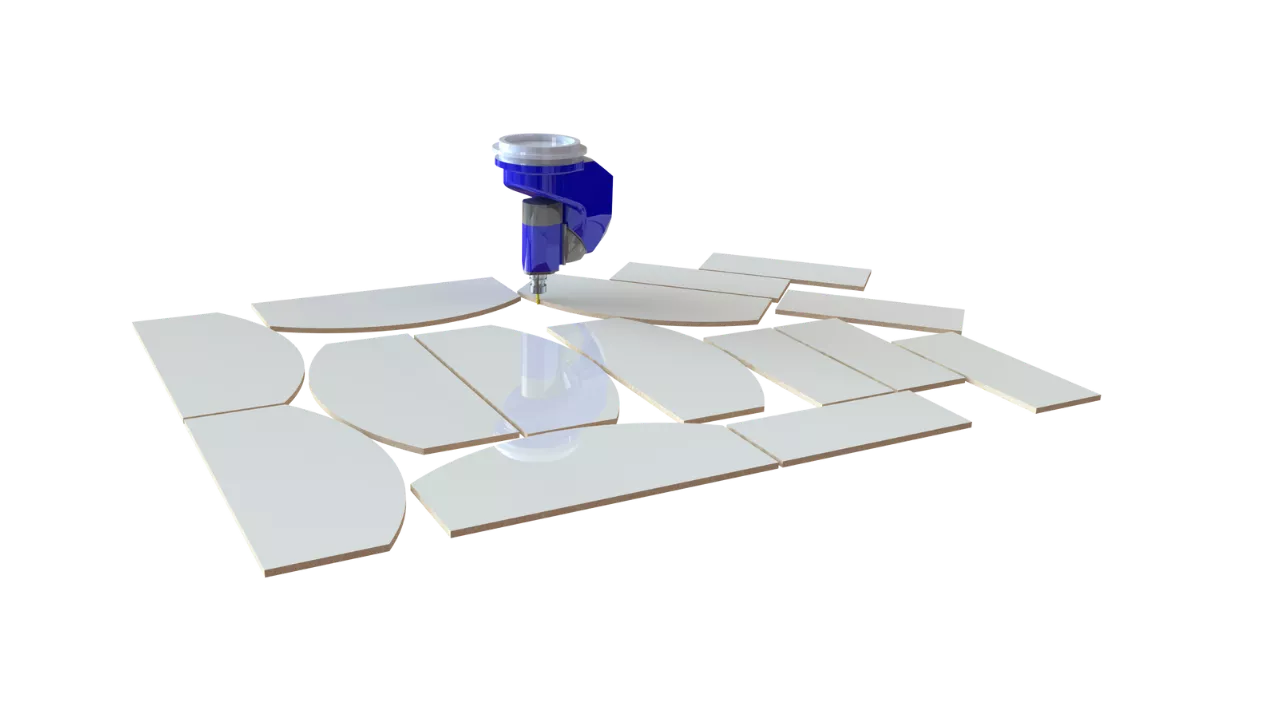

SWOOD Nesting automatically places multiple parts onto sheet materials for CNC machining, optimizing layouts to reduce material waste and cut production costs. Whether using rectangular or complex freeform shapes, it calculates the most space-efficient arrangement, saving time, improving efficienccy, and maximizing sheet usage.

Nesting Fronts and Finished Panels

SWOOD Nesting is designed to handle finished parts like cabinet fronts, doors, and drawer faces that demand careful attention to grain direction, orientation, and surface visibility. By maintaining consistent grain flow and supporting precise part alignment, it helps ensure high-end visual continuity across furniture components. The tool also allows users to prioritize surface quality and material matching, making it easier to meet premium design and manufacturing standards.

Bridges and Tabs for Part Holding

To maintain part stability during CNC cutting, especially for smaller or detailed pieces, SWOOD Nesting allows you to add customizable bridges (tabs). These temporary connections hold parts in place during machining, reducing the risk of shifting or damage. You can define the size, position, and number of tabs, making it easier to handle parts safely and efficiently afer cutting, ideal for vacuum tables and high-speed routing setups.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services