Stratasys F370 3D Printer

Versatile and Robust FDM 3D Printing

Now Serving US & Canada

Now Serving US & Canada

Versatile Meets Affordable 3D Printing

Invest in a more capable, affordable professional rapid prototyping solution for your entire office — from the leader in 3D printing. The Stratasys F370 features the largest build tray, and material capacity in the F123 Series, with a 14" x 10 x 14 " print area and 5 material options.

F370 MATERIALS

-

-

ABS-CF10

- Potential Applications:

– Tooling

– Jigs and fixtures

– Production and assembly

– Drill guides

-

ABS-CF10 Combines standard ABS material with 10% carbon fiber by weight . This makes for a 50% stiffer than standard ABS 3D printing material and 15% stronger than standard ABS 3D printing materials.

- Learn More >

-

-

ABS-ESD7

- Potential Applications:

– End-use components

– Electronic products

– Industrial equipment

– Jigs & fixtures

-

ABS-ESD7 standard FDM thermoplastic works with soluble support technology, so support removal is hands-free and complex parts require no extra effort.

- Learn More >

-

-

ABS-M30

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

-

ABS-M30 FDM material enables you to prototype quickly and efficiently. This strong, familiar material lets you explore more ideas, test frequently, work iteratively – and ultimately take better products to market faster.

- Learn More >

-

-

ASA

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

-

Mechanical strength and UV stability make ASA a great choice for functional prototyping. Ease of use makes it a top pick for iterative design. Outstanding aesthetics and ten fade-resistant colors make it an all-around favorite, even for end-use parts.

- Learn More >

-

-

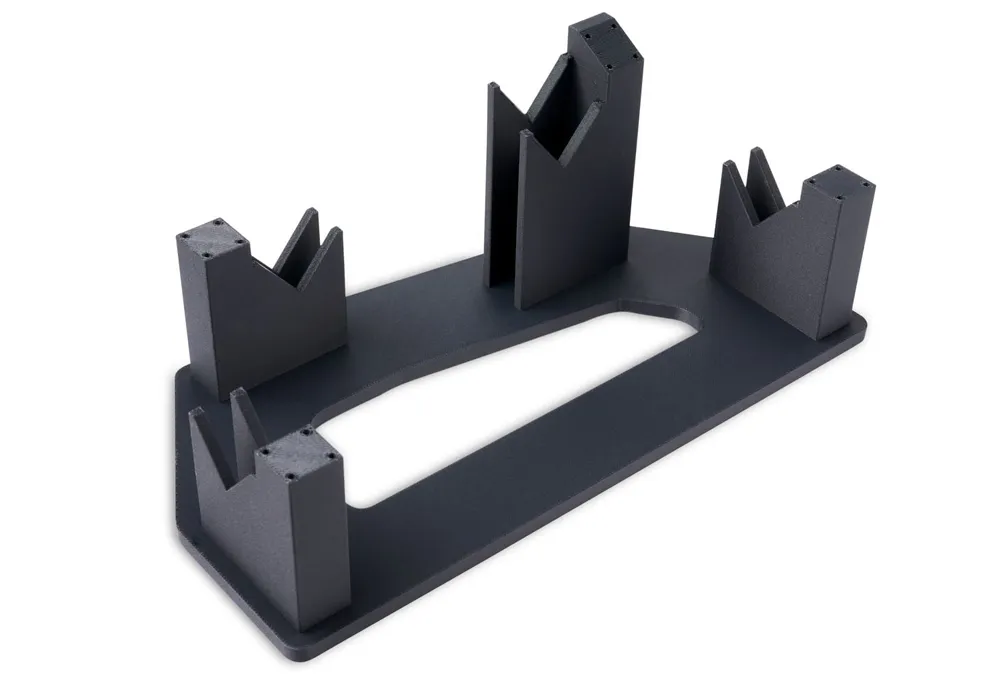

Diran

- Potential Applications:

– Tooling

– Jigs & fixtures

-

Displaying functional properties of chemical resistance, high-impact strength, and a low coefficient of friction this material is well-suited for jigs and fixturing applications where non-marring robust tooling is desired.

- Learn More >

-

-

FDM TPU 92A

- Potential Applications:

– Hoses, tubes, air ducts

– Protective covers & seals

– Vibration dampeners

– Prototype and end-use parts

-

Thermoplastic polyurethanes otherwise known as TPU’s are flexible elastomers found in products that require a soft touch, shock absorption, or a comforting grip. They are commonly co-molded or over-molded onto ABS and Polycarbonate substrates in sunglasses and phone/tablet cases.

- Learn More >

-

-

pc-abs

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

-

For functional prototyping, tooling, and low-volume manufacturing that requires superior impact strength, FDM Technology works with PC-ABS thermoplastic. PC-ABS also exhibits excellent feature definition and surface finish.

- Learn More >

-

-

PLA

- Potential Applications:

– Low-cost iterations

– Conceptual prototypes

-

Polylactic Acid otherwise known as PLA is an entry-level grade of thermoplastic material commonly associated with the ‘hobbyist’ FFF based printers because it builds well in systems that do not have closed-loop thermal control of the build chamber.

- Learn More >

Specifications

System Size and Weight

1,626 x 864 x 711 mm (64 x 34 x 28 in.), 227kg (500 lbs) with consumables

Noise Specification

46 dB maximum during build, 35 dB when idle

Accuracy

Parts are produced within an accuracy of +/- .200 mm (.008 in), or +/- .002 mm/mm (.002 in/in), whichever is greater.

Network Connectivity

Wired: TCP/IP protocols at 100 Mbps minimum 100 base T, Ethernet protocol, RJ45 connector

Wireless-ready: IEEE 802.11n, g, or b; Authentication: WPA2-PSK, 802.1x EAP; Encryption: CCMP, TKIP

System Requirements

Windows 7, 8, 8.1 and 10 (64 bit only) with a minimum of 4GB RAM (8 GB or more recommended)

Operating Environment

Operating: Temperature: 59 – 86 ºF (15 – 30 ºC), Humidity: 30 – 70% RH

Storage: Temperature: 32 – 95 ºF (0 – 35 ºC), Humidity: 20 – 90% RH

Power Requirements

100–132V/15A or 200–240V/7A. 50/60 Hz

Regulatory Compliance

CE (low-voltage and EMC directive), FCC, EAC, cTUVus, FCC, KC, RoHs, WEEE, Reach

Available Material

ABS-CF10, ABS ESD7, ABS-M30, ASA, *Diran, FDM TPU 92A, PC-ABS, PLA, QSR Support material (*Diran requires SUP4000B support material)

Build Tray Dimension

355.6 x 254 x 355.6 mm (14 x 10 x 14 in.)

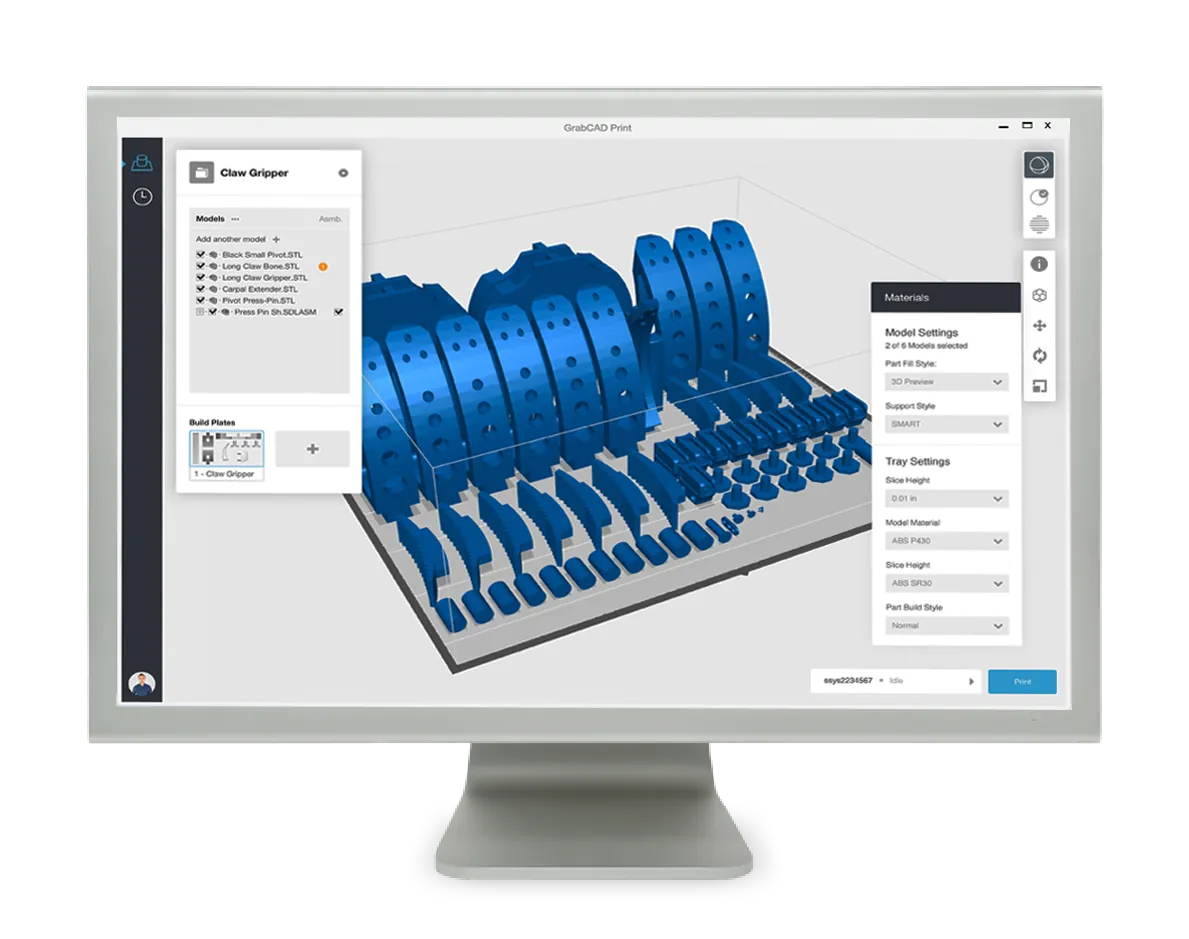

Software

Insight Software, GrabCAD Print

Software

GrabCAD Print

Professional 3D Printing Made Easy and Accessible

GrabCAD Print is the most complete solution for Stratasys 3D printers on the planet. The intuitive, easy-to-use software allows for simplified preparation, scheduling, monitoring, and reporting of print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management in shared office and model shop environments.

INSIGHT SOFTWARE

OPTIMIZE BUILD OUTPUT FOR 3D PRINTING

(ONLY AVAILABLE ON F370) Insight software prepares your CAD program’s STL output for 3D manufacturing on a Fortus machine by automatically slicing and generating support structures and material extrusion paths. For maximum control, users can manually edit parameters that determine the look, strength, and precision of parts as well as the speed and material use of the FDM process.

- Optimize build orientation for maximum strength and smoothest surface finish

- Customize supports for fast, easy removal and best use of materials

- Program pauses into the build for any reason, such as to embed hardware or circuitry

- Manipulate tool paths for advanced control over part properties

Included with Insight is Control Center. This sophisticated software application communicates with user workstations and Fortus systems, to manage jobs and monitor production status. Design, engineering, and manufacturing teams can network and share 3D manufacturing capacity to maximize efficiency and throughput.

*Compatible with GrabCAD Print for use with job reports, scheduling, and remote monitoring.

ADDITIONAL F-SERIES 3D PRINTERS

F-SERIES

View the Entire F-Series office friendly addditive manufacturing product line available from Stratasys. F-Seriesl 3D PrintersADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services