STRATASYS J5 DentaJet

3D Print Dental Parts with Accuracy and Ease

Now Serving US & Canada

Now Serving US & Canada

High output, affordable price

From producing orthodontic appliances to fixed restorations, the Stratasys J5 DentaJet can help your lab deliver on a wide array of cases with speed and efficiency. The rotating print platform combined with the ability to print different materials simultaneously brings ease and efficiency to every job. Allowing users to load a large tray area with a diverse array of prints, and walk away.

“The cool thing about the whole Separator DM process is that we were trying to fix one problem, which was to improve the finish on our appliances, and we actually fixed a lot of other problems.”

– Christian Saurman, CEO of NEO Lab

Features

COMPACT

The best-in-class footprint to printing tray ratio on the market means less bulk in your lab.

Ultra Quiet

The J5 operates under 53 decibels, about the same as a refrigerator.

Easy To Use

Requires zero mechanical calibrations and features a “ready-to-print” mode.

Quality

High resolution, fast prints, and a full-color range.

Harness the power of color

Wow clients with realistic replicas of treatments before getting to work. Set your lab apart with full color prints that communicate the true aesthetic possibilities.

3D Printing, simplified.

The J5 DentaJet is like having three printers in one. Reduce costs by using different materials in a single job, and printing what you need when you need it. Superior quality is now achievable for all, thanks to the small footprint and unattended operation capability of the Stratasys J5 D

A Solution for every need

The potential of the J5 DentaJet's applications are astounding:

Orthodontics: 3D print bonding trays, produce full color study models, and simplify the production of acrylic devices.

Crown and Bridge: Produce a large volume of precise models, and enable dentists to seat crowns and bridges in minutes.

Implantology: Print biocompatible and transparent surgical guides, rigid implant models, and soft gingiva masks - all in one tray.

Removables: Replace hand wax-ups and automate the process of cast chrome partials. Reduce patient visits and resets with precise frameworks produced in less time.

J5 Dentajet Materials

|

|

VeroGlaze MED620

Opaque rigid biocompatible dental resin

VeroGlaze™ MED620™ is a biocompatible dental resin designed for various applications in the field of restorative and orthodontic dentistry. With its rigid and opaque properties, this resin offers exceptional dimensional stability and accuracy. It is ideal for printing restorative and orthodontic models, custom impression trays, and try-ins. Moreover, VeroGlaze™ MED620™ is suitable for applications that involve prolonged skin contact exceeding 30 days, as well as short-term mucosal membrane contact of up to 24 hours.

Features:

- Biocompatible (ISO 10993-1 certified)

- Flexural strength: 75-110 Mpa

- I ZOD impact notched 20-30 J/m

- HDT 45-50°C

- Tensile strength 50-65 MPa

-

Color: Light Ivory (A2 shade)

Clear MED610

Transparent rigid biocompatible dental resin

Clear MED610™ is a biocompatible dental resin known for its rigidity and transparency, offering excellent dimensional stability. It is specifically designed for 3D printing surgical guides and removable partial denture casting patterns. This resin is suitable for applications that require prolonged skin contact exceeding 30 days, as well as short-term mucosal membrane contact of up to 24 hours. With its biocompatible properties, Clear MED610™ provides a reliable and versatile solution for dental applications.

Features:

- Biocompatible (ISO 10993-1 certified)

- Flexural strength: 75-110 Mpa

- IZOD impact notched 20-30 J/m

- HDT 45-50°C

- Tensile strength 50-65 MPa

- Color: Clear

Clear MED625FLX

FLexible Transparent biocompatible dental resin

MED625FLX™ is a biocompatible dental resin known for its flexibility and transparency. This resin is specifically designed for 3D printing orthodontic independent bonding trays and implant gingival masks. With its exceptional flexibility, it offers a reliable solution for creating precise and comfortable dental appliances. MED625FLX™ is suitable for applications that require prolonged skin contact exceeding 30 days, as well as short-term mucosal membrane contact of up to 24 hours. Its biocompatible properties make it a trusted choice for a range of dental applications.

Features:

- Biocompatible (ISO 10993-1 certified)

- Shore A Hardness 73-77

- Elongation at Break 45-55%

- Tensile strength 3.0-5.0 MPa

- Color: Clear

TrueDent

- FDA Approved

- Efficienct and Streamlined Workflow

- Precision and Standardization

- Customization and Patient Comfort

- Superior Material and Aesthetics

- Cost-Efficient

Potential applications:

-

Dentures

- Bases, Full & Partial Dentures, Denture Teeth

- Crowns

- Inlays & Onlays

- Veneers

VeroDent PureWhite DEN847

Bright white dental modeling resin

VeroDent PureWhite is a bright white photopolymer used either as a standalone material or as a foundation for creating realistic full-color models when combined with the Vero Vivid Color Family. This versatile resin provides excellent stiffness and enables the production of highly detailed and accurate models. It is specifically designed for 3D printing restorative and orthodontic models, ensuring reliable and precise results. Whether used on its own or in combination with other colors, VeroDent PureWhite offers outstanding quality and performance in dental applications.

Features:

- Excellent detail visualization

- Flexural strength: 75-110 Mpa

- IZOD impact notched 20-30 J/m

- HDT 45-50°C

- Tensile strength 50-65 Mpa

- Color: White

VERO Vivid Colors

Rigid translucent colored dental resins

Stratasys' Vero Vivid Colors Cyan/Magenta/Yellow RGD845/852/838™ are a set of translucent resins known for their exceptional dimensional stability. When combined with a core of VeroDent PureWhite on the J3 DentaJet, these resins enable the 3D printing of highly realistic full-color dental models. The vibrant cyan, magenta, and yellow colors provide a wide range of shades and hues, allowing for lifelike representation of dental anatomy. With their outstanding stability and compatibility with the VeroDent PureWhite core, these resins offer a reliable solution for creating visually stunning and accurate dental models.

Features:

- Excellent detail visualization

- Flexural strength: 75-110 Mpa

- IZOD impact notched 20-30 J/m

- HDT 45-50°C

- Tensile strength 50-65 Mpa

SUP711

Gel-like support material

The specially formulated SUP710™ support material exhibits a gel-like consistency, specifically engineered to provide robust support for overhangs and intricate geometries during the LED curing process of the J3 and J5 DentaJet 3D printers. Its unique properties ensure reliable support structures for complex dental models, enabling the production of highly accurate and precise prints. With SUP710™, users can achieve exceptional print quality while effectively addressing the challenges of overhangs and intricate designs in their dental 3D printing projects.

Compare Stratasys Dental 3D Printers

| All cases on 1-tray, high-efficiency printer with a smaller footprint for small to medium dental labs. | All cases on 1-tray, high-efficiency & cost-effective printer with a smaller footprint for all dental labs and model production. | All cases on 1-tray, high-efficiency printer with a smaller footprint for all dental labs. | High throughput DLP solution utilizing P3 Technology with a small footprint that is optimized for accurate and quick prints for multiple applications. | |

| Applications |

Dental tooling (small-medium volume):

|

Dental tooling (high-volume):

|

Dental tooling (high-volume):

|

Dental Tooling (high volume):

Dental end user parts (high volume):

|

|

Model

Materials |

|

|

|

|

|

Max

Materials |

3 | 2 | 5 | 1 |

| Support Material | SUP711 (Waterjet removable) | SUP711 (Waterjet removable) |

SUP711 (Waterjet removable) |

N/A |

| Software | GrabCAD Print | GrabCAD Print | GrabCAD Print | Fusion 360 with Netfabb Premium |

|

Cartridge

Capacity |

1.1kg | 4kg | 1.1kg | N/A |

|

Tray Size

and Area |

Round Print Tray with up to 1.174 cm 2 | Round Print Tray with up to 1,174 cm 2 | Round Print Tray with up to 1,174 cm 2 |

192 x 108 x 370 mm (7.5 x 4.25 x 14.5 in)

205 cm 2 |

|

System Size

and Weight |

651 x 661 x 774mm (25.63 x 26.02 x 30.48 in.); 98 kg (216 lbs.) |

650 x 1520 x 660 mm (25.6 x 59.8 x 26 in); 199 kg (439 lbs.) |

651 x 661 x 1511mm

(25.63 x 26.02 x 59.49 in.): 228 kg (503 lbs) |

490 x 5110 x 1130 mm (19 x 20 x 44 in)

81 kg (180 lbs) |

| Technology | PolyJet | PolyJet | PolyJet | Programmable PhotoPolymerization P3 (Digital Light Processing) |

Stratasys J5 DentaJet Specifications

BIOCOMPATIBLE Materials

- Biocompatible Clear MED610™

- VeroGlaze™ (MED620)

- Flexible clear biocompatible material MED625FLX™

-

Vibrant colors including:

- VeroCyanV™ (RGD845)

- VeroMagentaV™ (RGD852)

- VeroYellowV™ (RGD838)

- VeroDent™ PureWhite (DEN847)

Support Materials

SUP711™ (Water Jet removable)

Build Size

Up to 1,174cm²

Max Part Size: Up to 140 x 200 x 190mm (5.51 x 7.87 x 7.48in.)

Layer Thickness

Horizontal build layers down to 18 microns (0.0007 in.)

Workstation Compatibility

Network Connectivity

System Size and Weight

System: 651 x 661 x 1511mm (25.63 x 26.02 x 59.49 in.); 228 kg (503 lbs.)

Operating Conditions

Temperature 18-25 °C (64-77 °F); relative humidity 30-70% (non-condensing)

Power Requirements

1 00– 240 VAC, 50–60 Hz, 10A, 1 phase

Regulatory Compliance

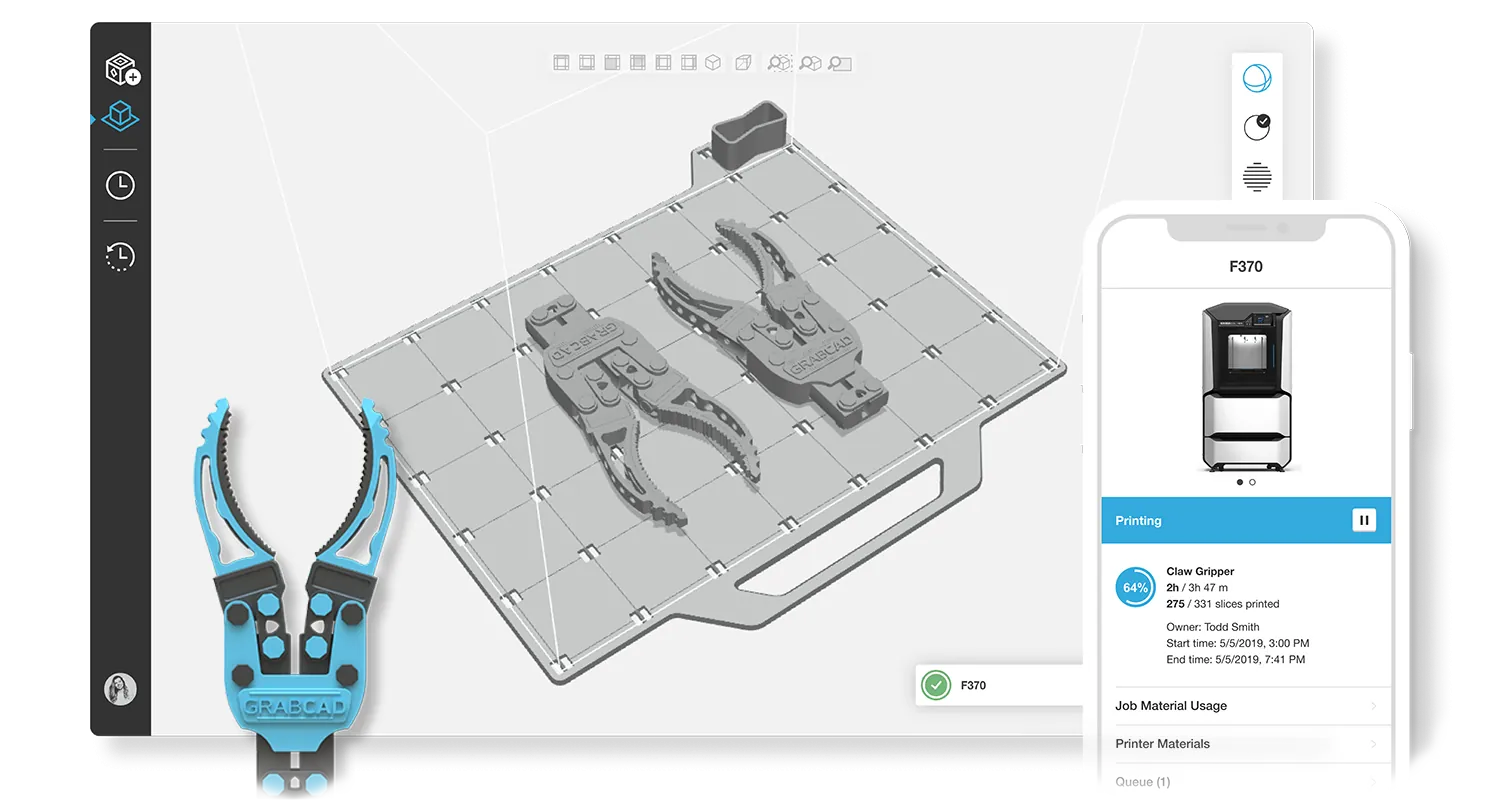

Software

GrabCAD Print

Build Modes

High-Quality Speed: 18.75um

Software

GrabCAD Print

GrabCAD Print makes 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

Additional 3D Printers

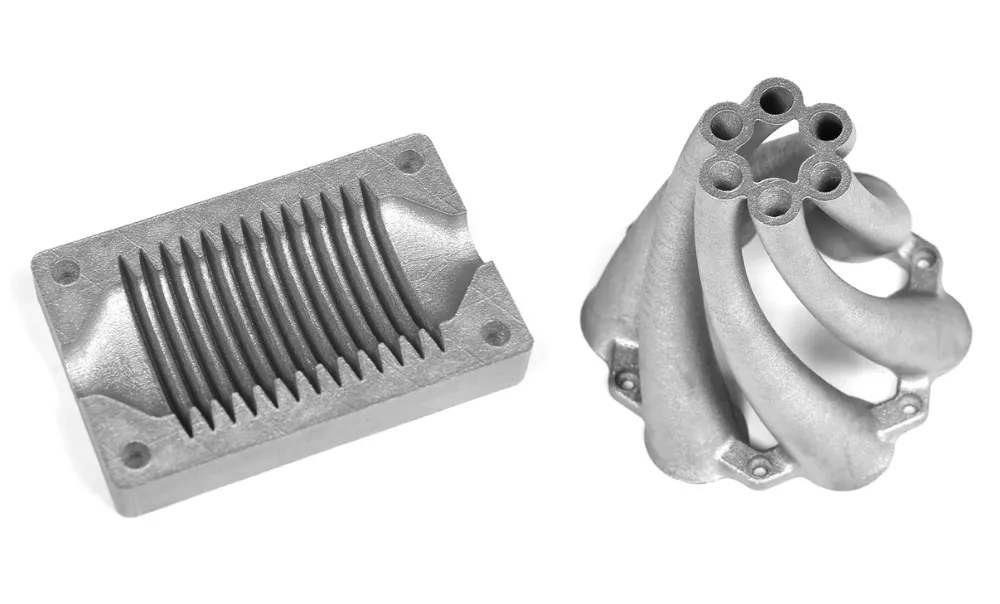

FDM

FDM 3D printers streamline processes from design through manufacturing, reducing costs and eliminating traditional barriers along the way. Manufacturing FDM 3D PrintersMETAL

3D print functional metal parts and prototypes for industrial, commercial, and private applications. Metal 3D PrintersSAF

Selective Absorption Fusion™ SAF™ technology that delivers functional, production grade parts with optimum consistency. Production SAF 3D PrintersP3

Programmable PhotoPolymerization P3™ technology delivers industry leading accuracy, consistency, and details. Production P3 3D PrintersADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services