3DEXPERIENCE ADDITIVE MANUFACTURING

A Virtual Workplace to Create & Validate 3D Printing Programs

Industrial-scale additive manufacturing is a growing trend with the potential to revolutionize many industries, but it needs to be reliable, predictable, and cost-effective.

3DEXPERIENCE ADDITIVE MANUFACTURING tools provide easy-to-use machine programming workflows that optimize material usage, improve part quality, and speed up the printing process. Users can save and reuse process standards that ensure consistency and quality across the company.

“We chose a

3D

EXPERIENCE Works Simulation solution because it’s cloud-based, which supports our remotely located engineering organization, works seamlessly with SOLIDWORKS design data, and incorporates the Abaqus Explicit solver, which is best suited for the types of simulation studies that we need to conduct on our parts, which can involve hyperelasticity, creep, fatigue, and contact.”

– Thomas Morgan

Design Engineer

HIGHLIGHTS

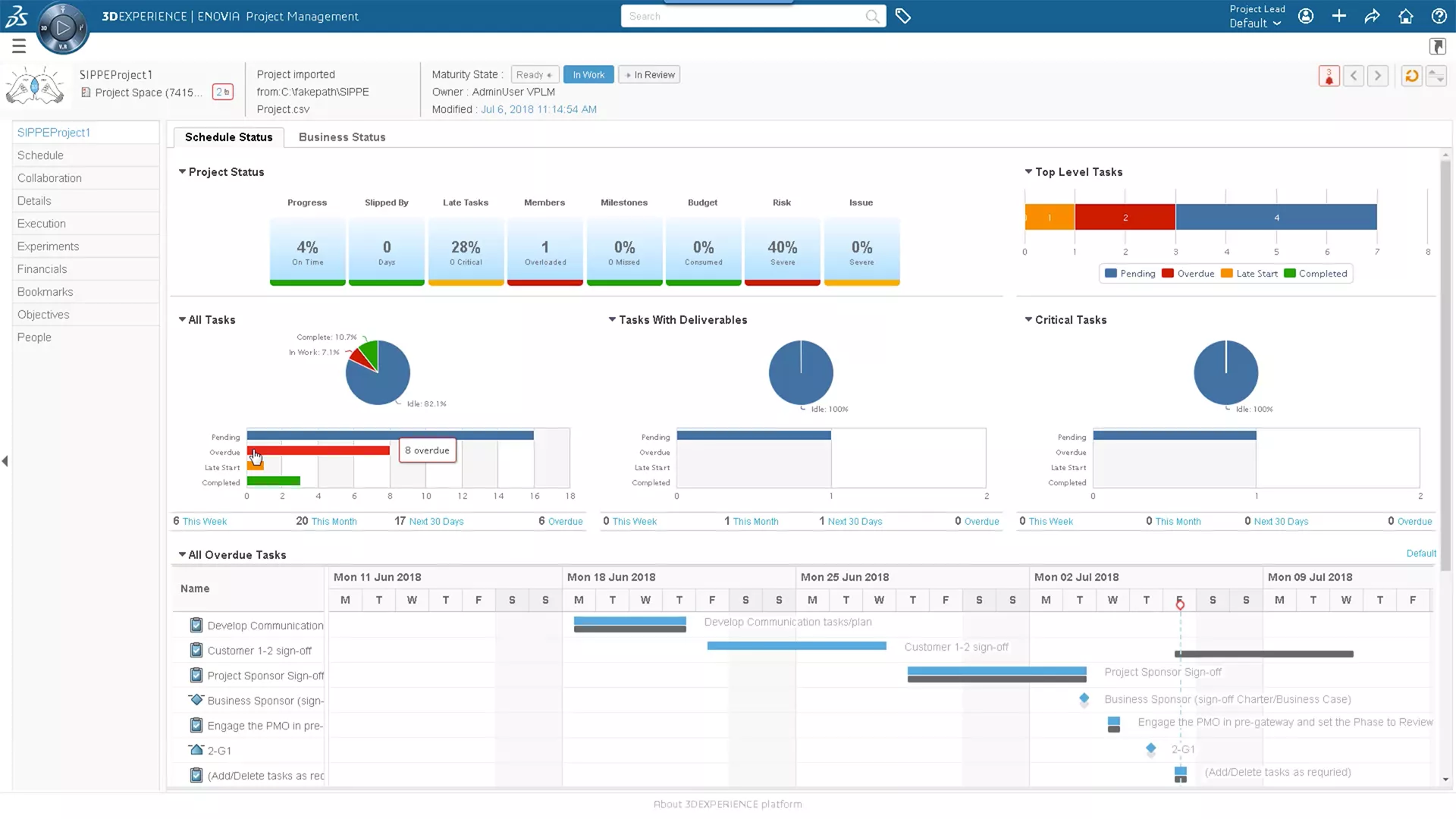

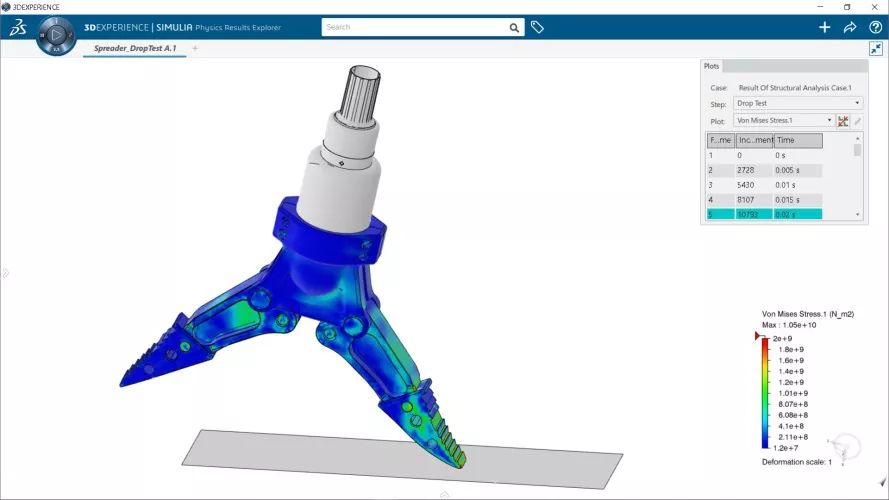

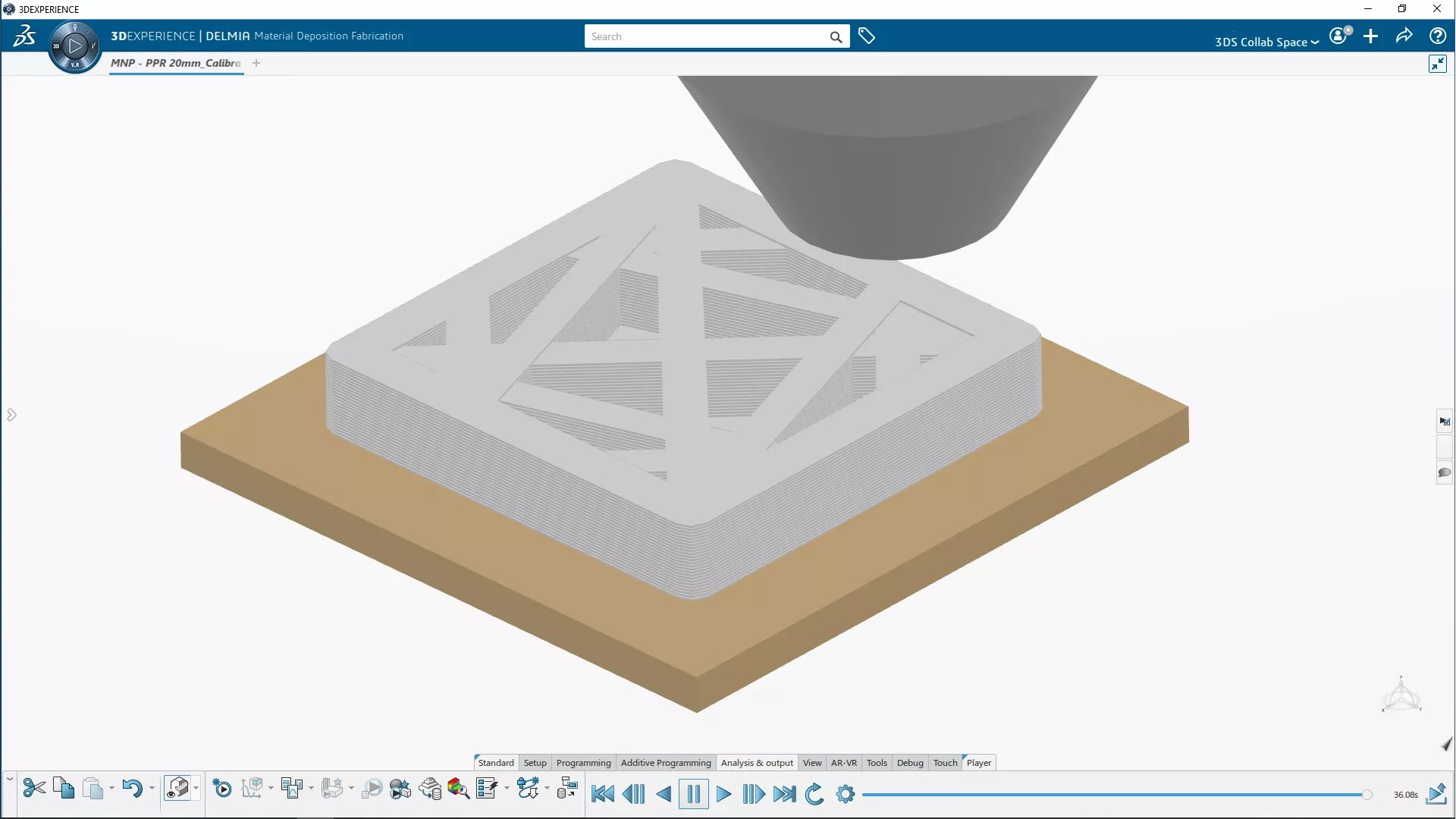

Validate Before You Print

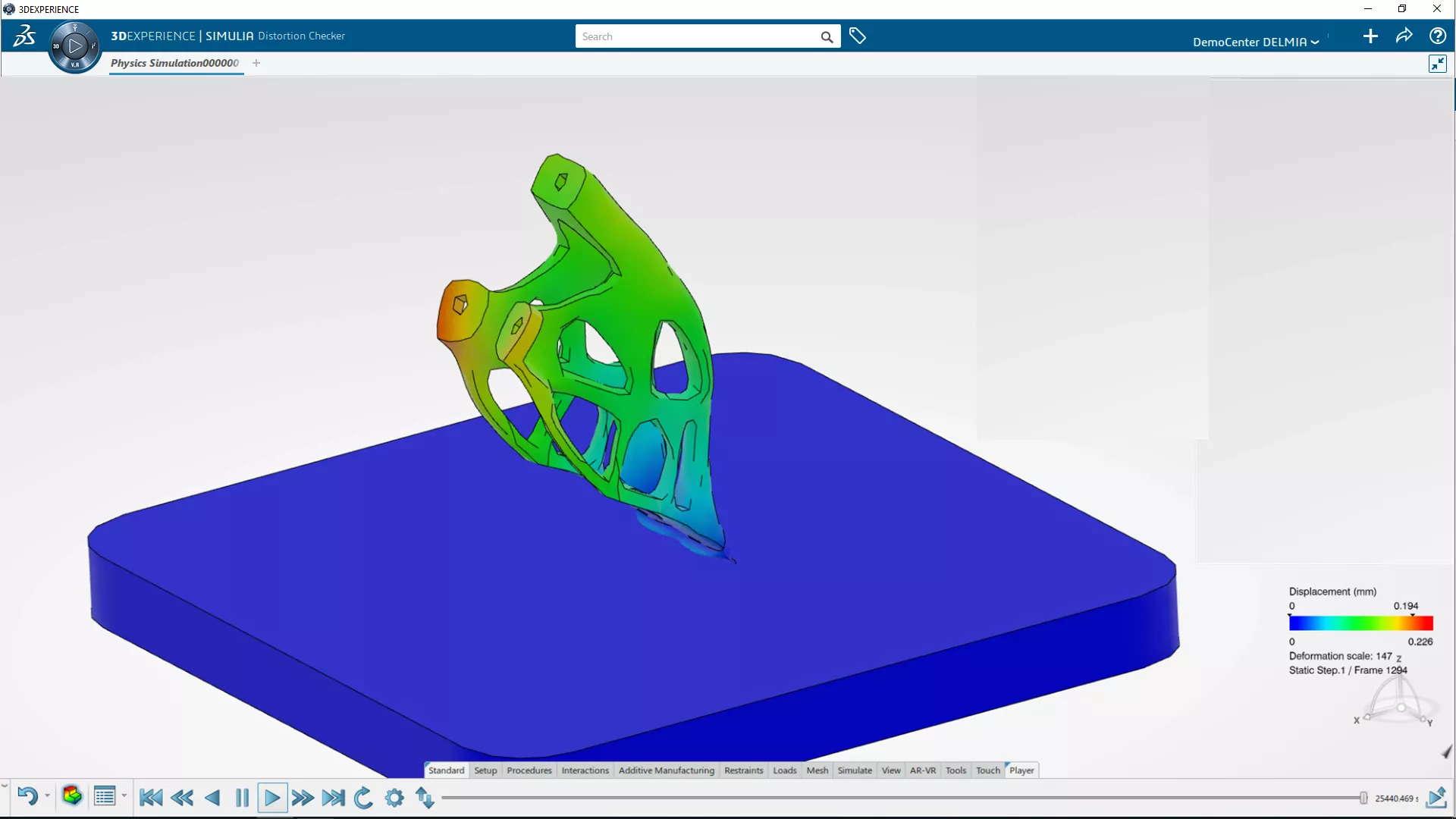

A virtual manufacturing environment allows programmers to predict the quality of the printed parts and the printing process before commiting real-world resources.

Validate material choices and laser parameters; ensure laser paths respect the physical layout of machines, accessories, and tooling; simulate print distortions and generate compensating geometry.

With these capabilities, companies can avoid unexpected and costly production delays.

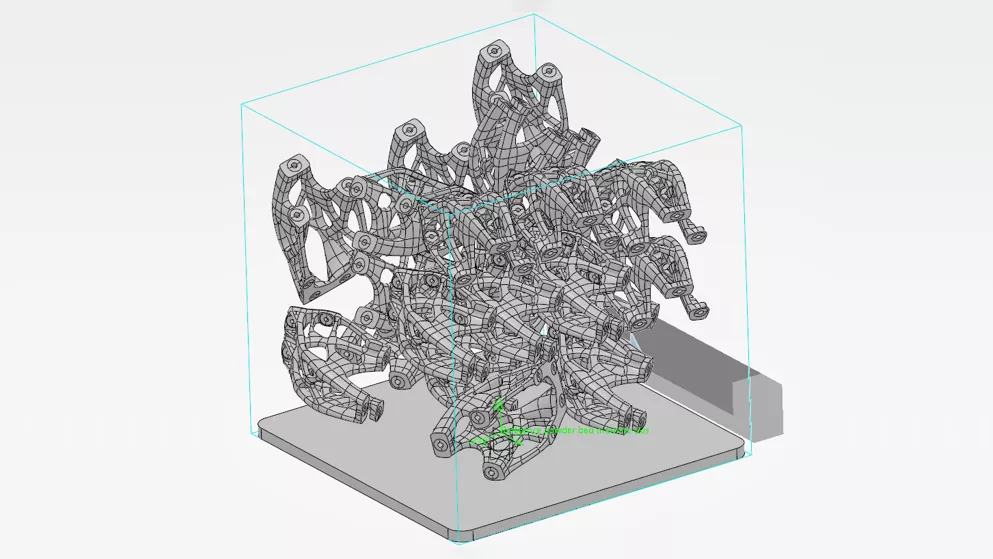

Maximize Resource Utilization

3DEXPERIENCE additive programming solutions provide the tools to achieve faster prints with less waste. A wide range of material deposition operations and strategies minimize non-value-added motion. Advanced 3D nesting capabilities ensure optimal use of powder bed space with fewer supports.

When combined with a "digital validation first" approach to 3D printing, companies can save tremendous amounts of time and money.

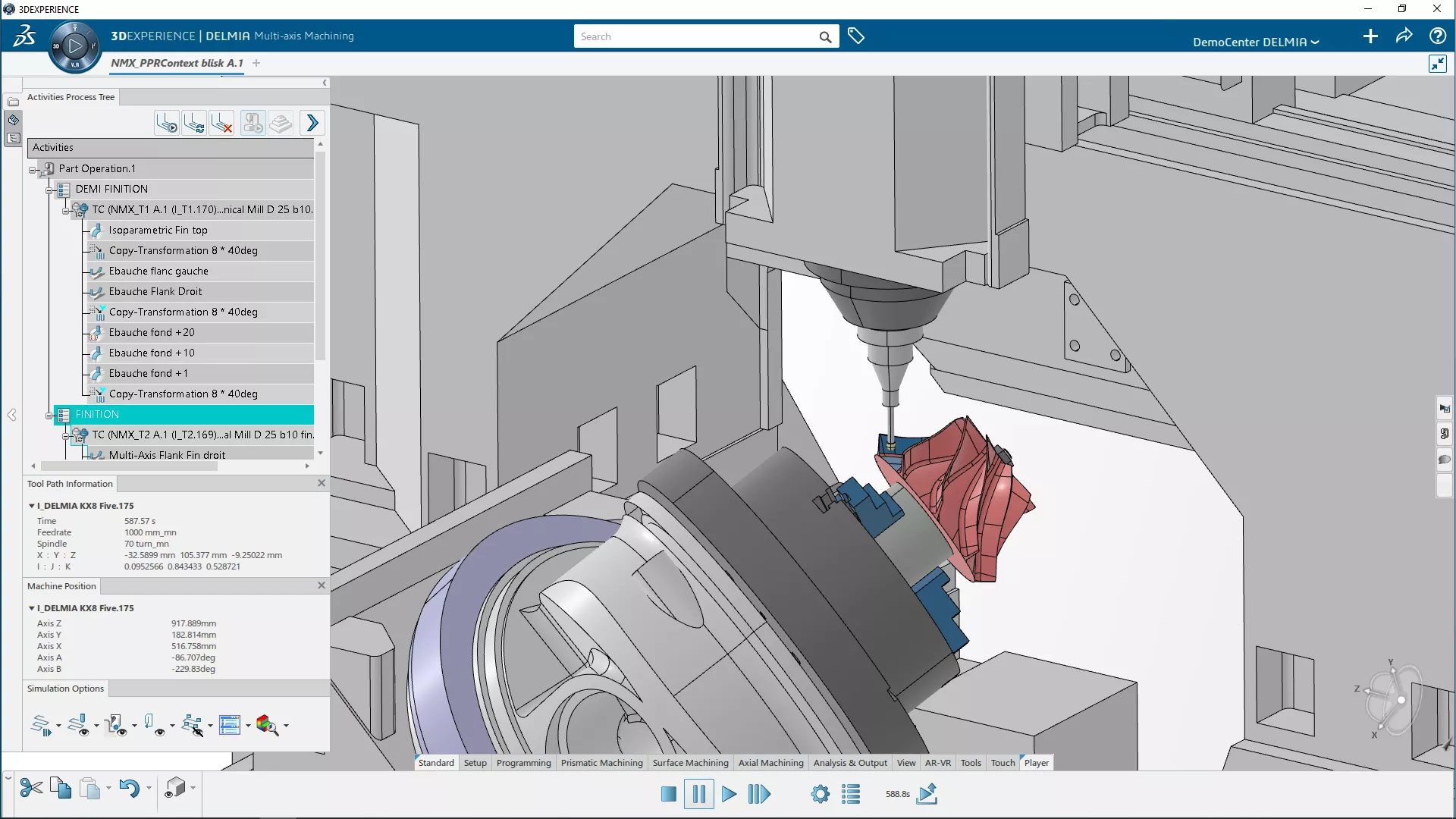

Program Quickly and Easily

- Program single and multi-laser systems in a convenient and familiar 3DEXPERIENCE interface

- Automatically generate part placements, part orientations, and support structures

- Easily modify geometry with boolean operations or complex surface manipulation

Leverage Intellectual Property

Users can define and store machining processes as dedicated templates, and keep them in catalogs for future use.

By automating, standardizing, and reusing company intellectual property, gains to productivity and machining-work standardization become significant.

Rapidly Respond to Changes

The 3DEXPERIENCE platform provides native associativity between machining programs and engineering and manufacturing data.

Companies can better manage concurrent engineering and manufacturing, shorten the design-to-manufacturing cycle, rapidly program for design changes and variations, and respond effectively to engineering or manufacturing changes.

Feature Matrix

OPTION

OPTION

OPTION

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

CASE STUDY

Learn how Morgan Polymer Seals accelerated their seal development to meet electric vehicle market demand with 3D EXPERIENCE Works Simulation.

3DEXPERIENCE ADDITIVE MANUFACTURING Products

-

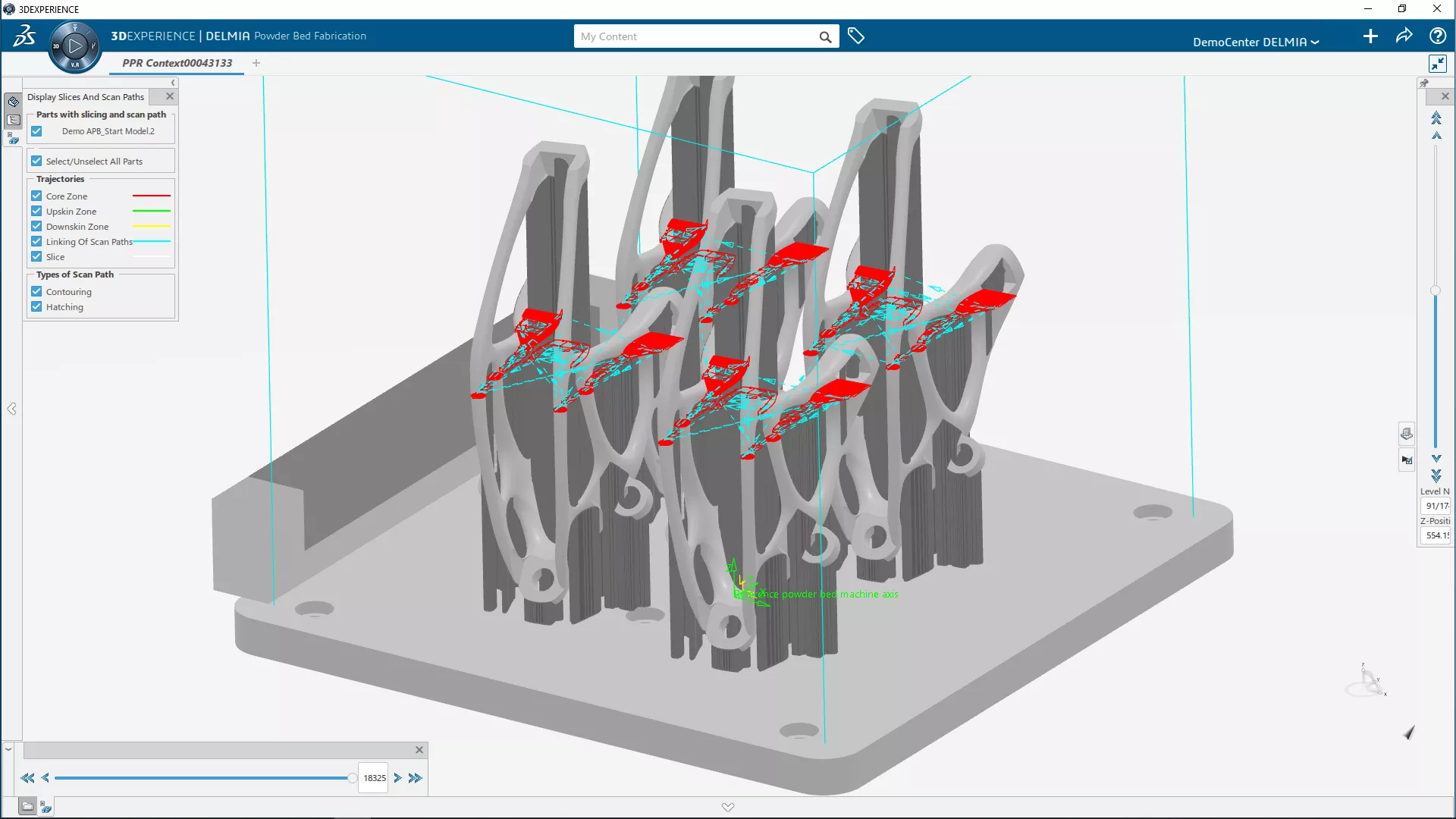

Powder Bed Machine Programmer

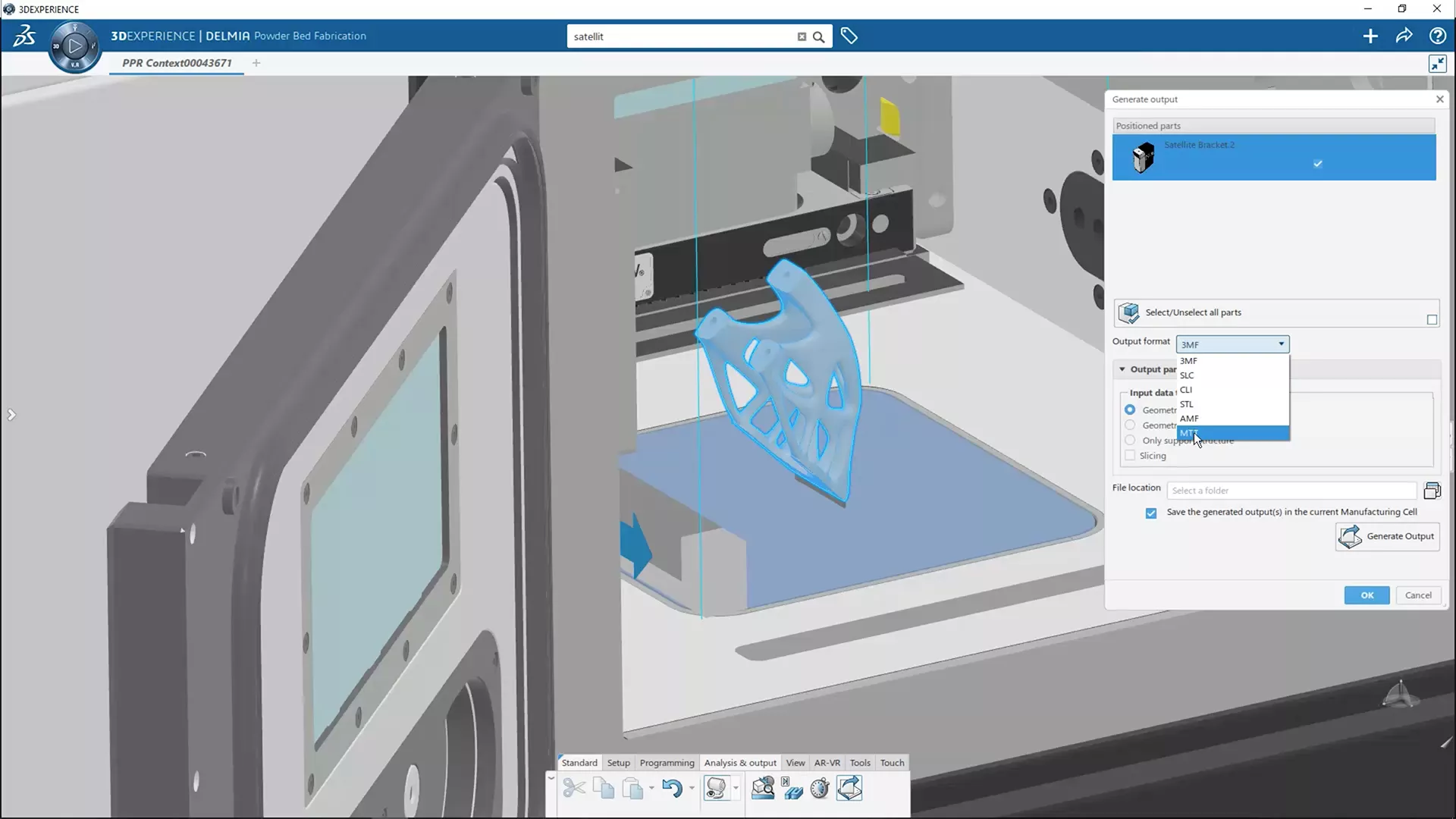

- Prepare, program, and validate the additive manufacturing process for powder bed 3D printers.

- Key Features:

- Printing process configuration and validation

- Multi-laser path programming and management

- Automatic part placement and orientation

- Automatic support generation

- Printed part validation and geometry rework

- Time and cost prediction

- Simplified user interface for non-expert users

- Save and reuse best practices - Typically used by:

Powder bed fusion researchers and machine programmers -

-

Powder Bed Machine Specialist

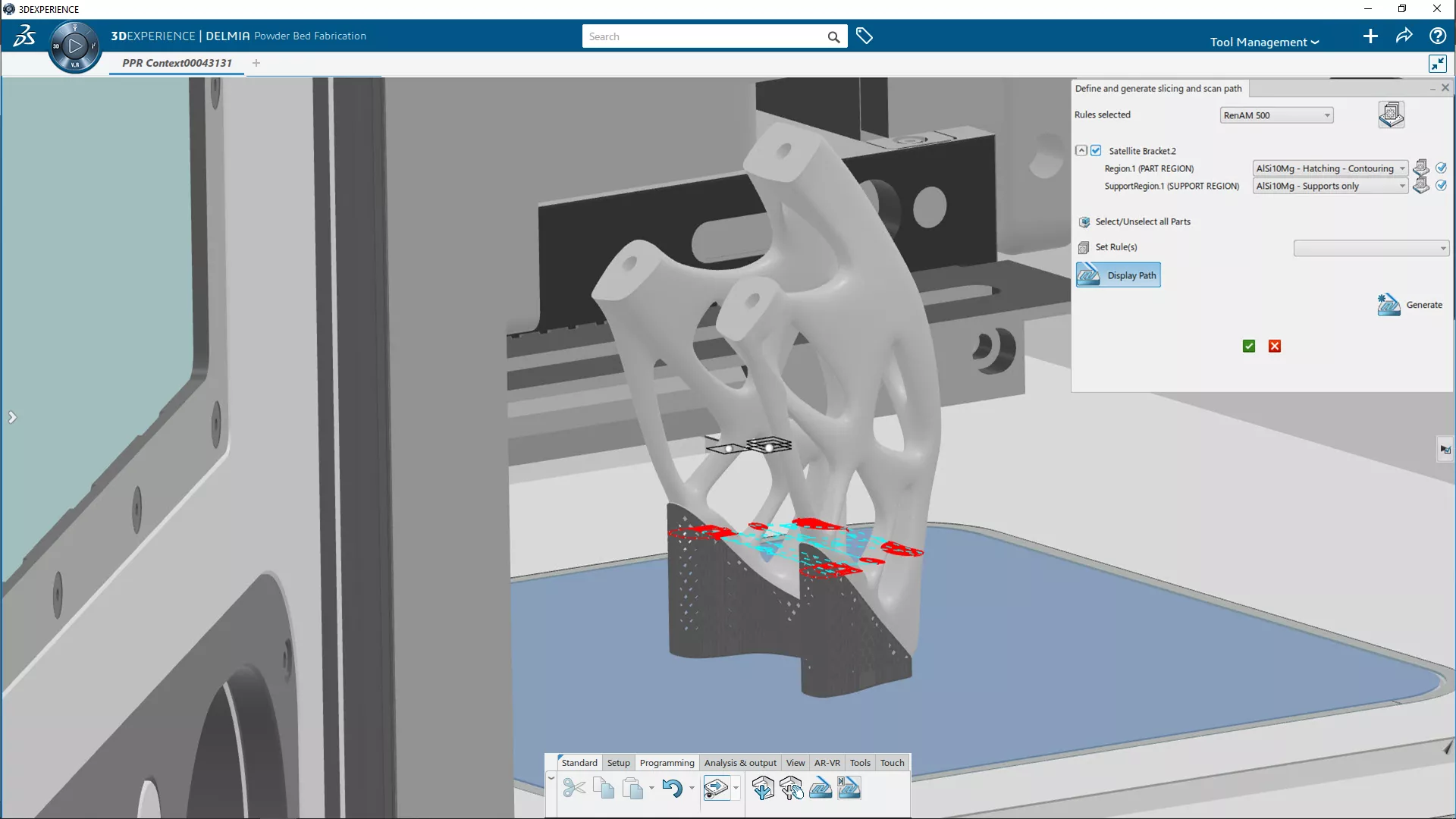

- Prepare, program, and validate the additive manufacturing process -- including part distortion simulation -- for powder bed 3D printers.

- Key Features:

- Printing process configuration and validation

- Multi-laser path programming and management

- Automatic part placement and orientation

- Automatic support generation

- Printed part validation and geometry rework

- Printed part distortion simulation and geometry compensation

- Time and cost prediction

- Simplified user interface for non-expert users

- Save and reuse best practices - Typically used by:

Powder bed fusion researchers and machine programmers concerned about part distortion -

-

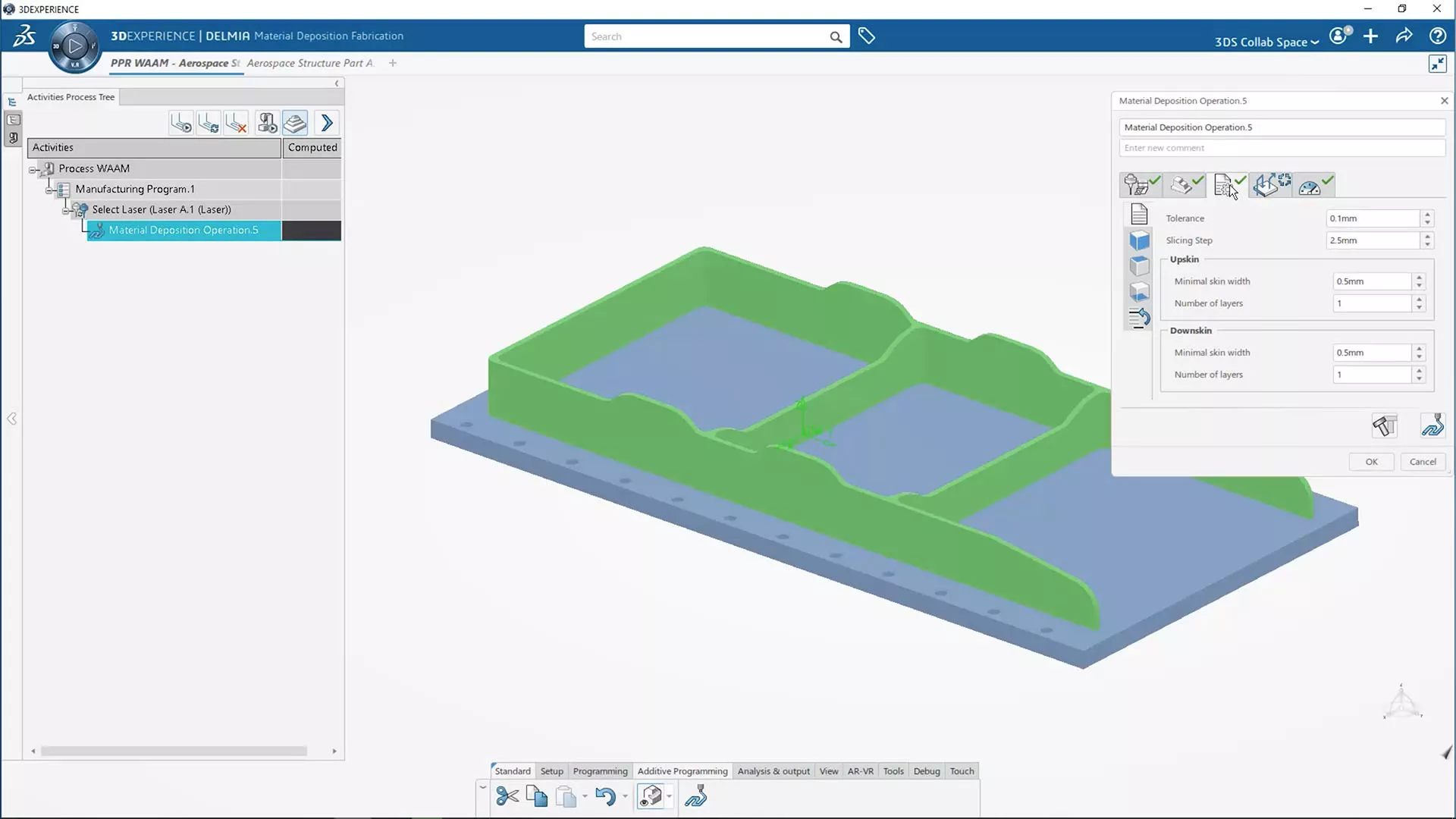

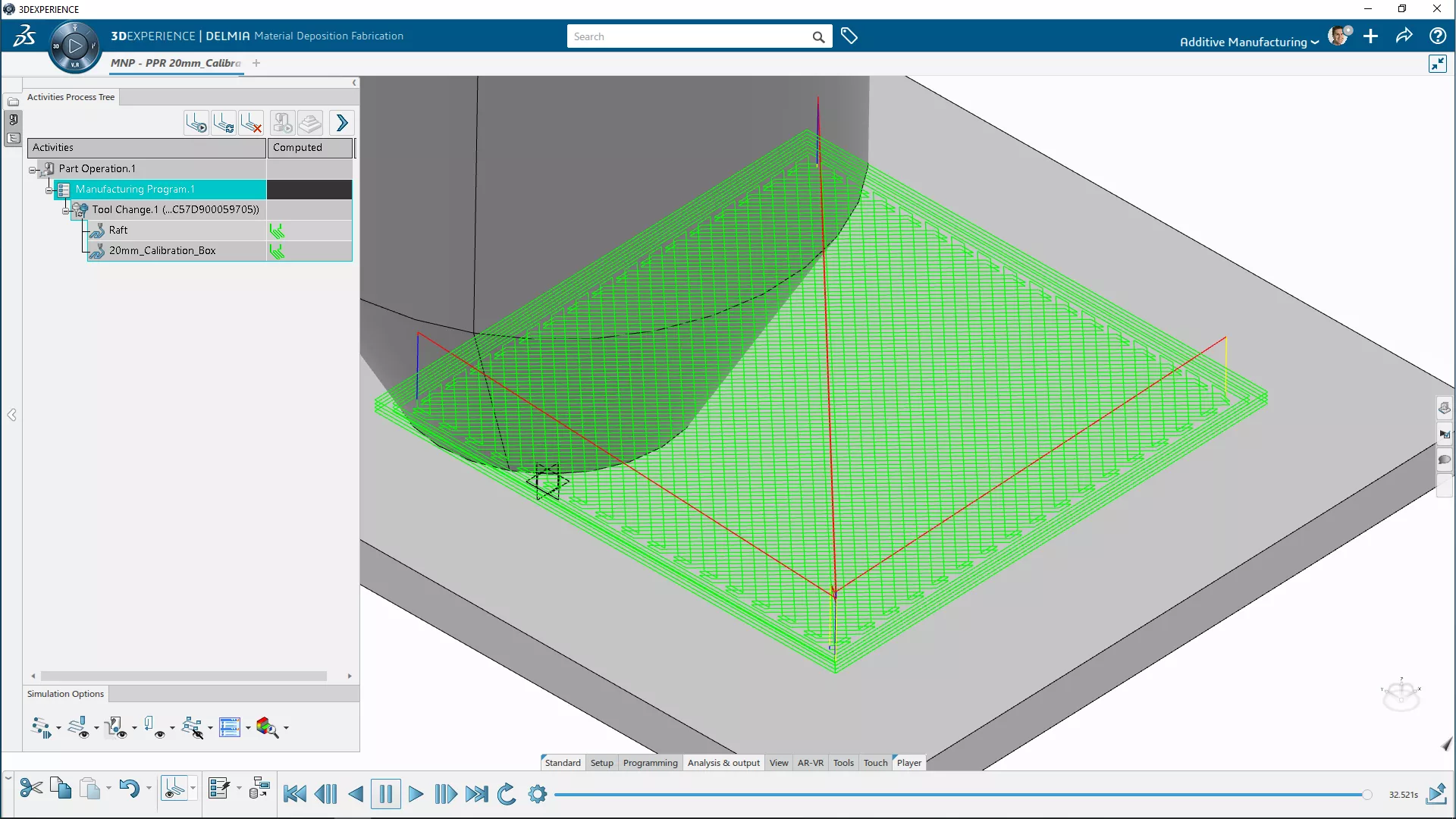

Material Deposition Machine Programmer

- Set up, program, analyze, and re-use additive manufacturing processes covering direct energy deposition and material extrusion techniques.

- Key Features:

- Virtual validation of the additive process

- Printing strategies can include contouring, hatching, hexagonal, neutral line, curve following, and 5-axis activities

- Create laser paths and adjust parameters such as power and melting depth

- Re-use best practice templates for laser paths or nozzle motions

- Prepare printed parts to support downstream applications like machining or wire EDM

- Add labels on parts for traceability

- Modify surfaces for complex shapes or hybrid parts

- Includes a library of 1700 robots - Typically used by:

Material deposition researchers and machine programmers -

Learning 3DEXPERIENCE Cloud PDM: Goengineer is here to help

More Connected Manufacturing Solutions For You

3DEXPERIENCE CLOUD PLM

Plan your definition of success with web-based cloud PLM tools that fully integrate design data.

3DEXPERIENCE STRUCTURAL

Top-end FEA for designers and analysts, powered by Abaqus in the cloud. Now with special additive manufacturing add-on.

3DEXPERIENCE NC PROGRAMMING

A realistic virtual workplace to create, enhance, and validate NC programs from live-linked, native CAD data.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services