DICOM-to-3D Print Medical Models: Methods Used to Compare Accuracy

As additive manufacturing continues to emerge in the medical sector, companies like Stratasys have developed advanced 3D printers and digital anatomy materials that replicate human bone and tissue characteristics. Surgeons use this technology for patient-specific pre-surgical practice—raising concerns about validating the accuracy of 3D printed anatomical models.

- Suggested Article >> Medical 3D Printing: Stratasys Technologies, Materials, & Applications

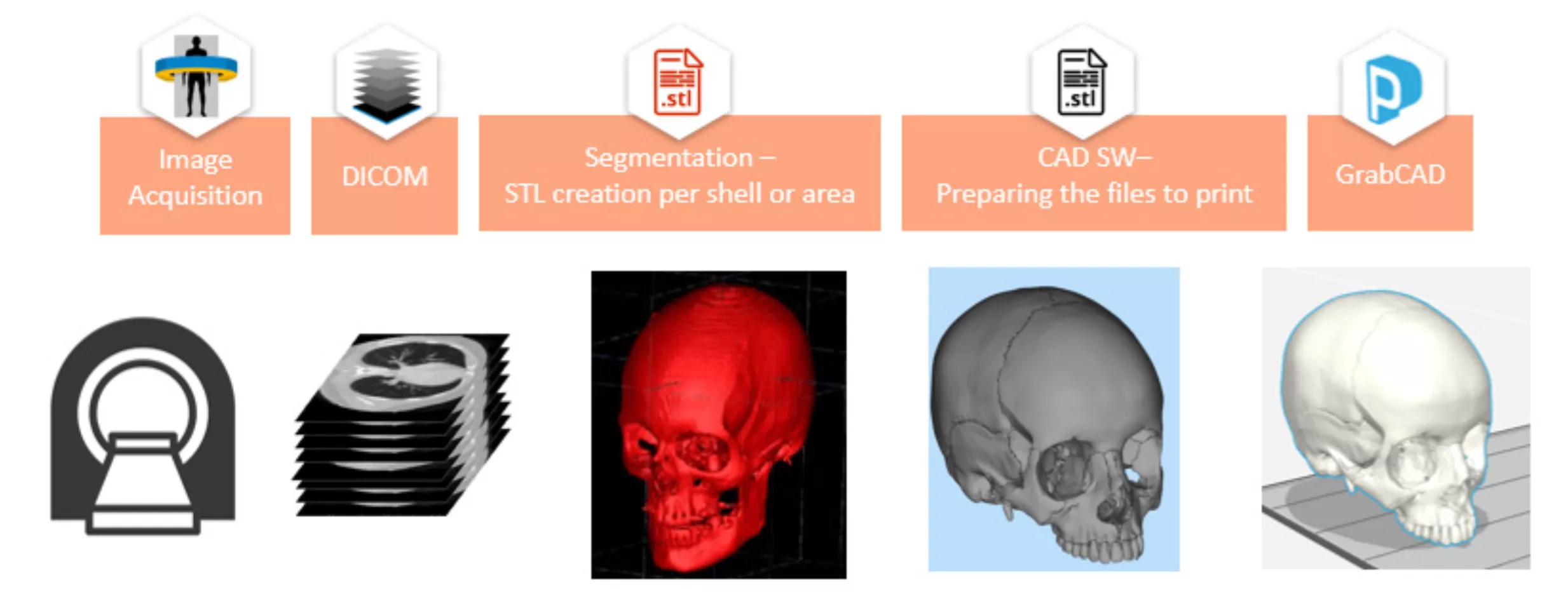

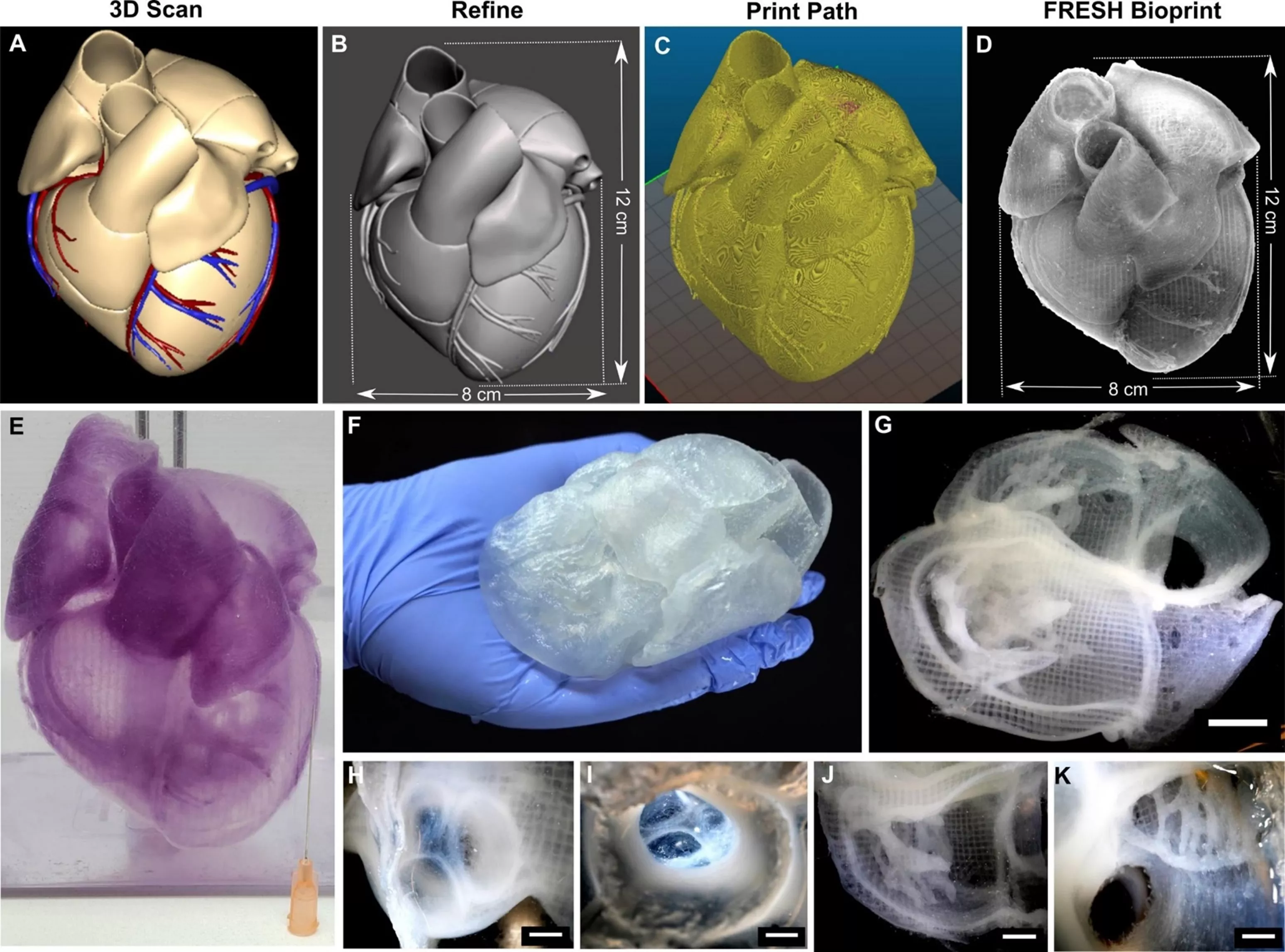

Medical parts are typically 3D printed from DICOM data acquired by CT or MRI scans. The data is then segmented to isolate the anatomical area of interest and converted into an optimized 3D mesh file. The digital file is then exported as an STL and is ready for 3D printing. Companies like Axial3D deliver advanced anatomical models from patient DICOM to 3D print workflow.

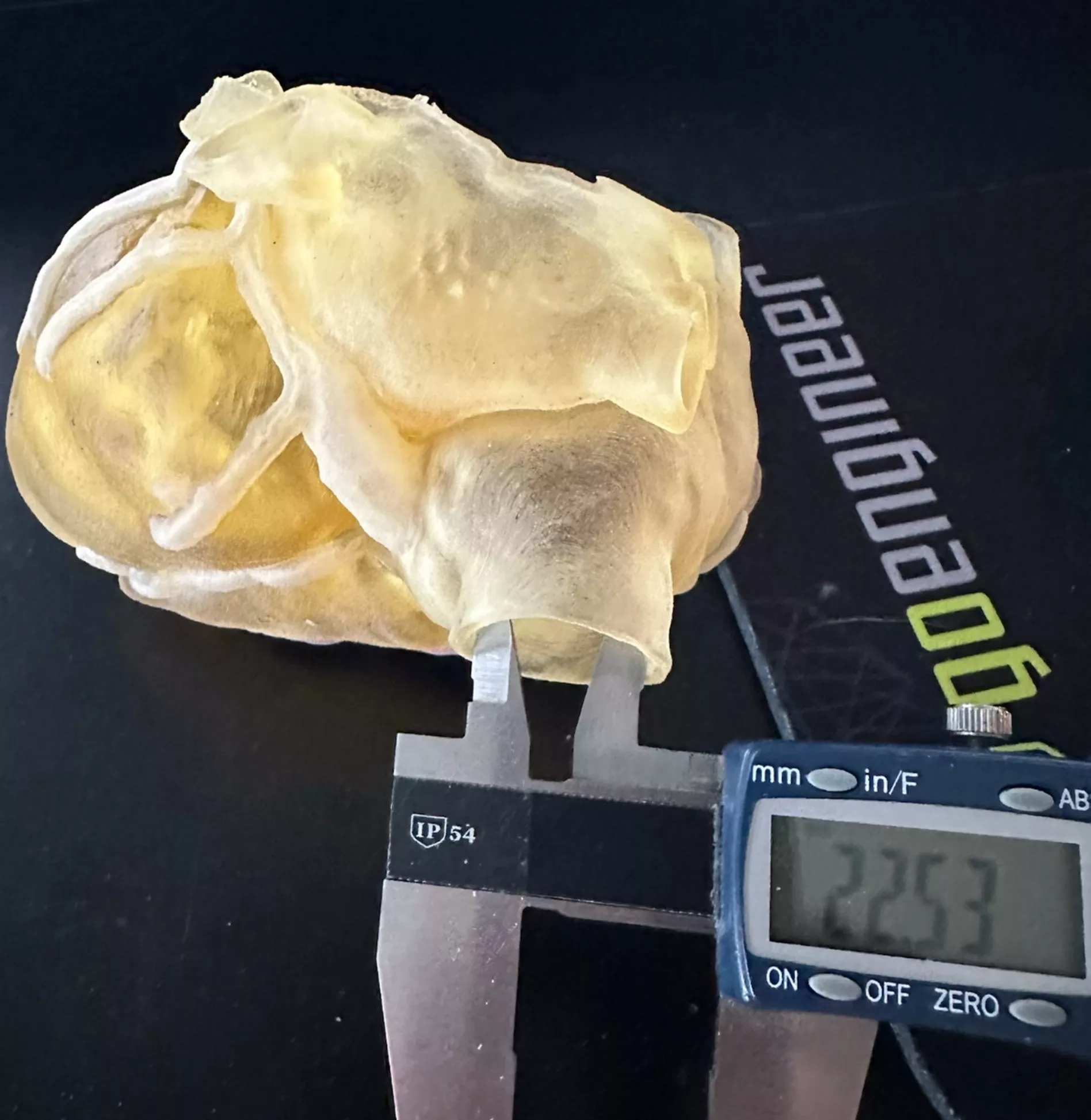

There are a few different methods for verifying the accuracy of 3D printed anatomical models compared to the native DICOM file. Verification provides confidence that the physical part made will fulfill the intended application and meet the customer and surgeon’s expectations. Since human anatomy has very organic shapes, measuring these models presents unique challenges.

Manual Measurement

Micrometers, calipers, and probes are just a few measurement tools commonly used to manually measure physical models. These instruments are used in industrial applications where critical tolerance and strict quality control are mandatory. Thickness, depths, and overall distance measurements can quickly and easily be achieved, but the multiple organic shapes and internal features can be difficult to access and validate.

Digital Imaging and Photogrammetry

Taking multiple photos from different angles of a part can be used to virtually measure or reconstruct and generate a three-dimensional model to compare to the STL and DICOM files. The photogrammetry technique offers the ability to compare non-linear surfaces but still possesses many challenges with internal structures. This process also requires a technician with extensive experience with digital photography, appropriate lighting, and stitching software to produce a quality digital 3D image. Improper lighting will result in overexposure and cause bleeding or blurred features. Lack of details may affect the accuracy of the measurements taken, compared to the STL.

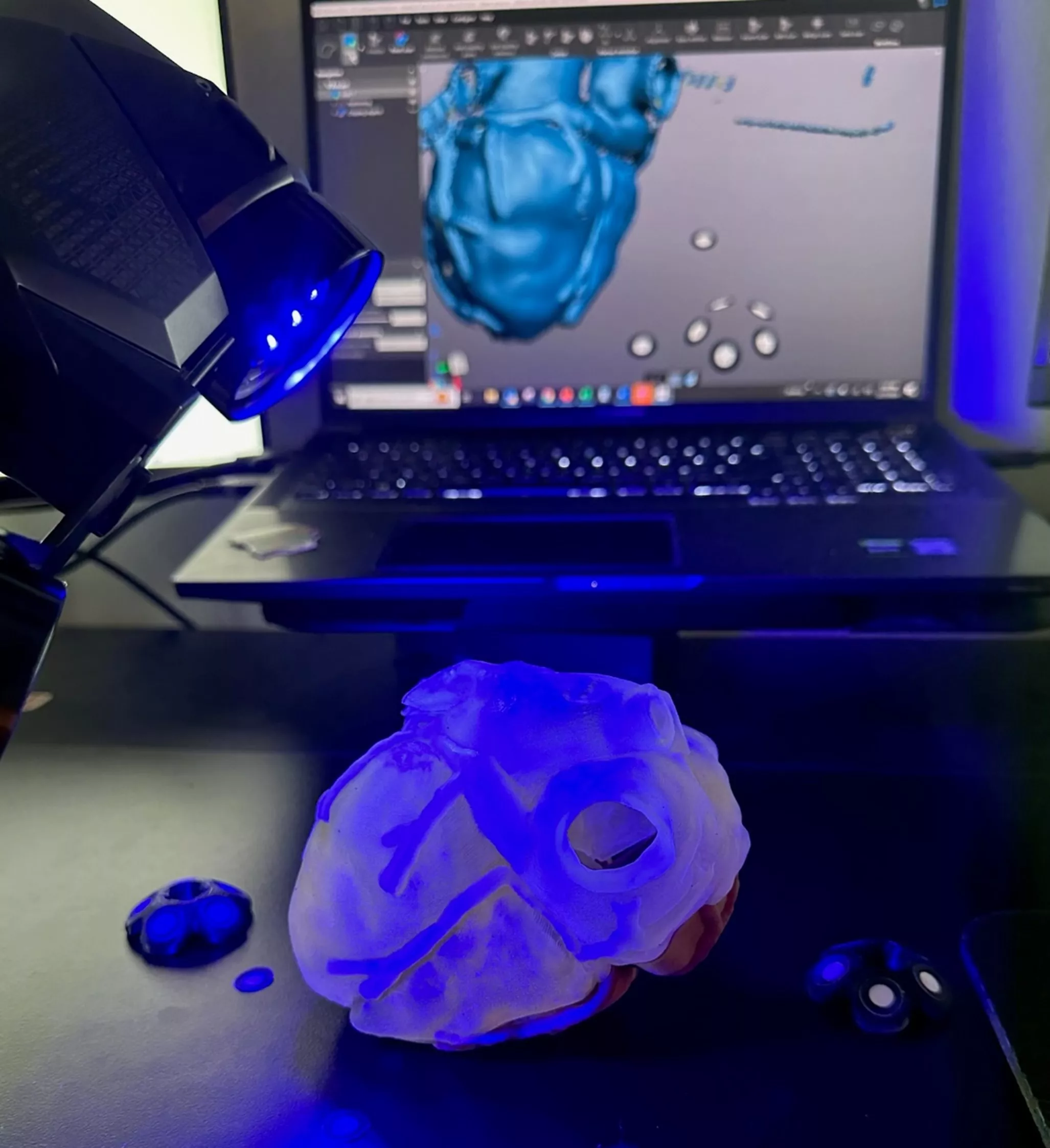

Optical Surface Scanning

Surface scanning using white light or laser-based 3D scanners is a great option for accurately capturing fine details and organic shapes versus traditional methods.

- Suggested Article >> Choosing a 3D Scanner: Light vs Lasers, Applications, & Considerations

Companies like Creaform and Artec 3D offer a variety of portable, metrology-grade scanners, which are incredibly useful for industries that require intense accuracy. However, similar to the other verification methods, internal features are impossible to capture. Like photogrammetry, this process requires a skilled technician to operate the device and optimize the mesh in post-processing software. However, the accuracy of the acquired data will provide much greater insight into the accuracy of the print.

X-Ray/CT Scanning:

CT scanning has been found to circumvent the challenge of acquiring internal structures no matter how complex the geometry. This process has proven the ability to validate the entire end-to-end workflow when comparing 3D printed parts to the original DICOM data. Additionally, radiologist staff have experience with CT technology, so additional training or personnel isn’t required to incorporate verification of the model. Verifying the model accuracy to DICOM is only one of many quality control regulations being put in place to standardize medical additive manufacturing.

Interested in learning more about medical additive manufacturing and Stratasys Digital Anatomy printers? Please contact us.

75% Reduction in Prototyping Costs ⋅ 50% Acceleration in Development time

Download this guide to learn how the medical industry is using 3D printing technology to acceleate time to market, optimize product design, elevate cost efficiencies, and reduce development risk.

Related Articles

Medical 3D Printing: Stratasys Technologies, Materials, & Applications

3D Printing in Healthcare: Redefining Surgical Outcomes

Stratasys J5 Digital Anatomy Printer: Small Footprint, Powerful Solutions

Medical 3D Printing: Advanced End-to-End Solutions for Surgeons

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.