Formlabs Fuse Sift: SLS Powder Dosing Made Easy

One of my favorite aspects of the Formlabs Fuse 1+ 30W SLS 3D printer is the design freedom that comes from using loose powder as a natural support structure. But once I’ve excavated my parts from a finished build, I’m left with a crucial question: what do I do with all the unsintered powder? Formlabs has designed the Fuse 1+ 30W to work with a mixture of fresh and reclaimed powder.

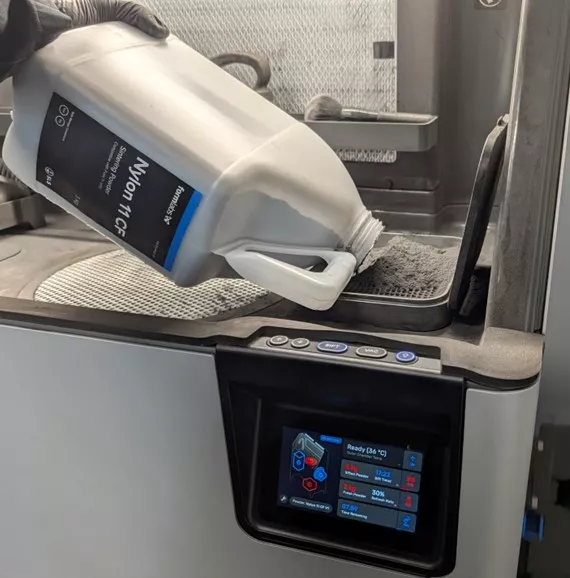

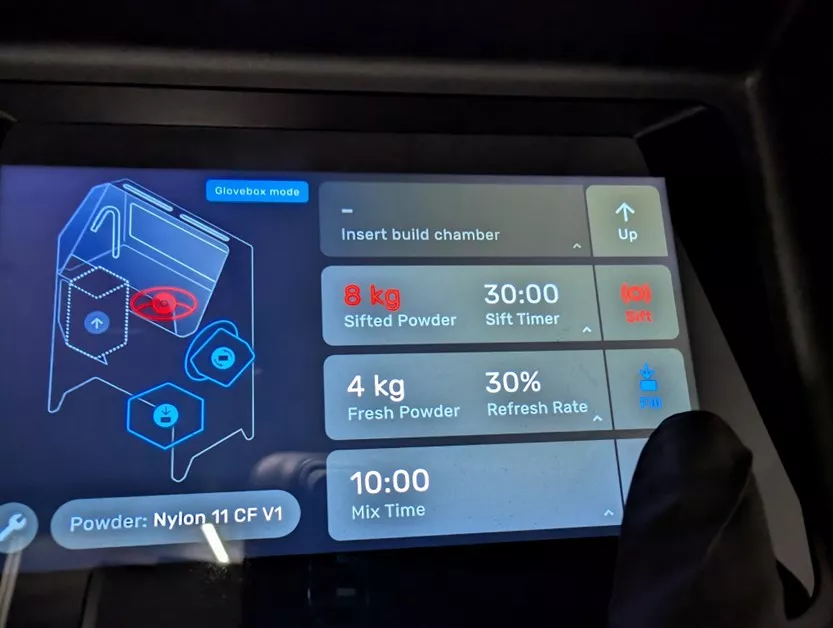

For my material choice of Nylon 11 CF, the recommended blend is 30% fresh to 70% reclaimed. This blending process is known as “dosing”, and it’s essential for maintaining part consistency, quality, and repeatability. Every time I load powder into the printer, the ratio must be precise, and the mixture must be thoroughly homogenized. While every compatible material has its own ideal ratio, the need for consistent dosing is a universal requirement.

Formlabs Fuse Sift

Formlabs built its ancillary equipment ecosystem with users like me in mind—people who thrive on workflows that are efficient, repeatable, and easy to use. This is where the Formlabs Fuse Sift shines.

It’s a self-contained post-processing workstation that handles the following process:

#1. Break out and sieve parts and load fresh powder in the adjacent hopper.

#2. Set the ratio on the UI and press the button to dial in your material’s required fresh-to-recycled powder ratio.

#3. Press the Fill button and let the Sift do the rest—no manual measuring, no guesswork.

That’s it. The result is a clean, homogenized powder blend ready to be loaded into the printer. I simply take the powder cartridge, top off the Fuse 1+ hopper, and start the next build. There’s a kind of magic in holding a functional, accurate 3D printed part in your hands—but it’s the behind-the-curtain processes like dosing that make that magic real.

At GoEngineer, we focus on delivering tools that make that hard work more accessible, more efficient, and frankly, easier. The Fuse Sift, as part of the Formlabs Fuse 1+ 30W ecosystem, hits all those marks. It’s not just about printing—it’s about building a smart, end-to-end workflow where nothing slows you down.

If you’re apprehensive about the mess and guesswork in powder dosing, it’s time to step out of the build-box. Contact us and discover how the Fuse 1+ 30W and Fuse Sift can transform your 3D printing process.

Related Articles

FDM Post-Processing: Oryx sca1200ht for Soluble Support Removal

How 3D Printing is Helping Manufacturers Fight Back Against Tariffs

Guide to Using Formlabs PreForm Software for SLA 3D Printing

DICOM-to-3D Print Medical Models: Methods Used to Compare Accuracy

Economic Change in Manufacturing Demands a New Approach by Leveraging 3D Printing

About Simon Pinter

Simon Pinter is a Manufacturing Solutions Application Engineer at GoEngineer

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.