GrabCAD Streamline Pro Software for Stratasys 3D Printer Fleet Management

GrabCAD Streamline Pro supercharges the operation of Stratasys 3D printing environments by simplifying the management of single machines to large, complex fleets. While not strictly required to run your printers, it is a platform I’ve come to rely on to keep operations flowing smoothly. It’s particularly helpful when managing high print volumes, multiple materials, tight schedules, and access controls, all from a unified, cloud-based interface.

Streamline Pro supports additive manufacturing operations by offering control over five key aspects: print job submission, queue management, machine oversight, analytics, and security. Here's how each component contributes to streamlining your daily workflow.

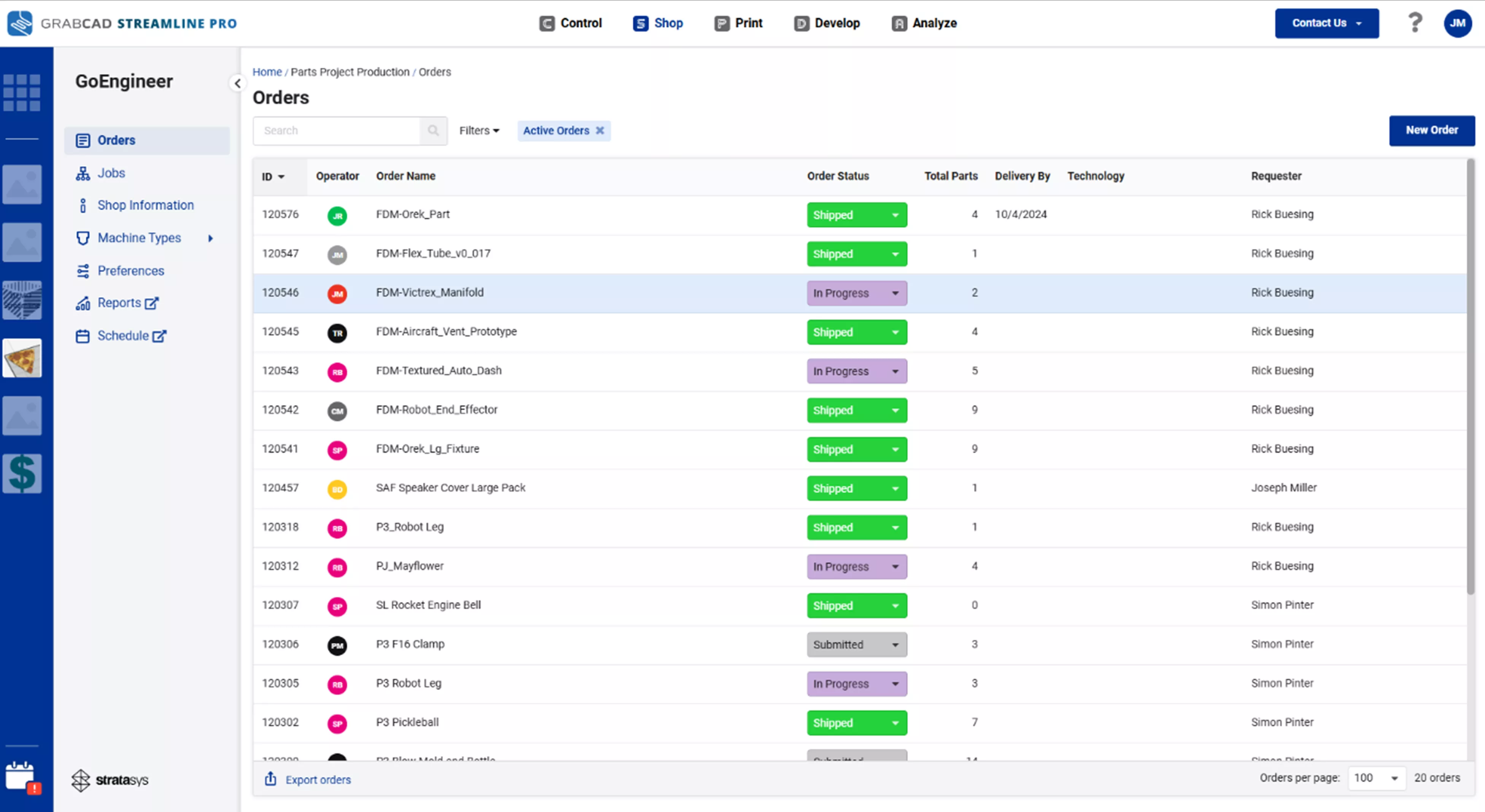

Print Job Submission

The Shop module serves as the front-end for requesting print jobs. It’s where team members can submit and track builds, ensuring that key information, like part dimensions, material selection, color preferences, and deadlines, is clearly captured up front.

Administrators can quickly prioritize jobs and assign them to printers based on capabilities and availability. In a shared production environment, this helps reduce communication errors and avoids bottlenecks caused by missing or unclear job specs.

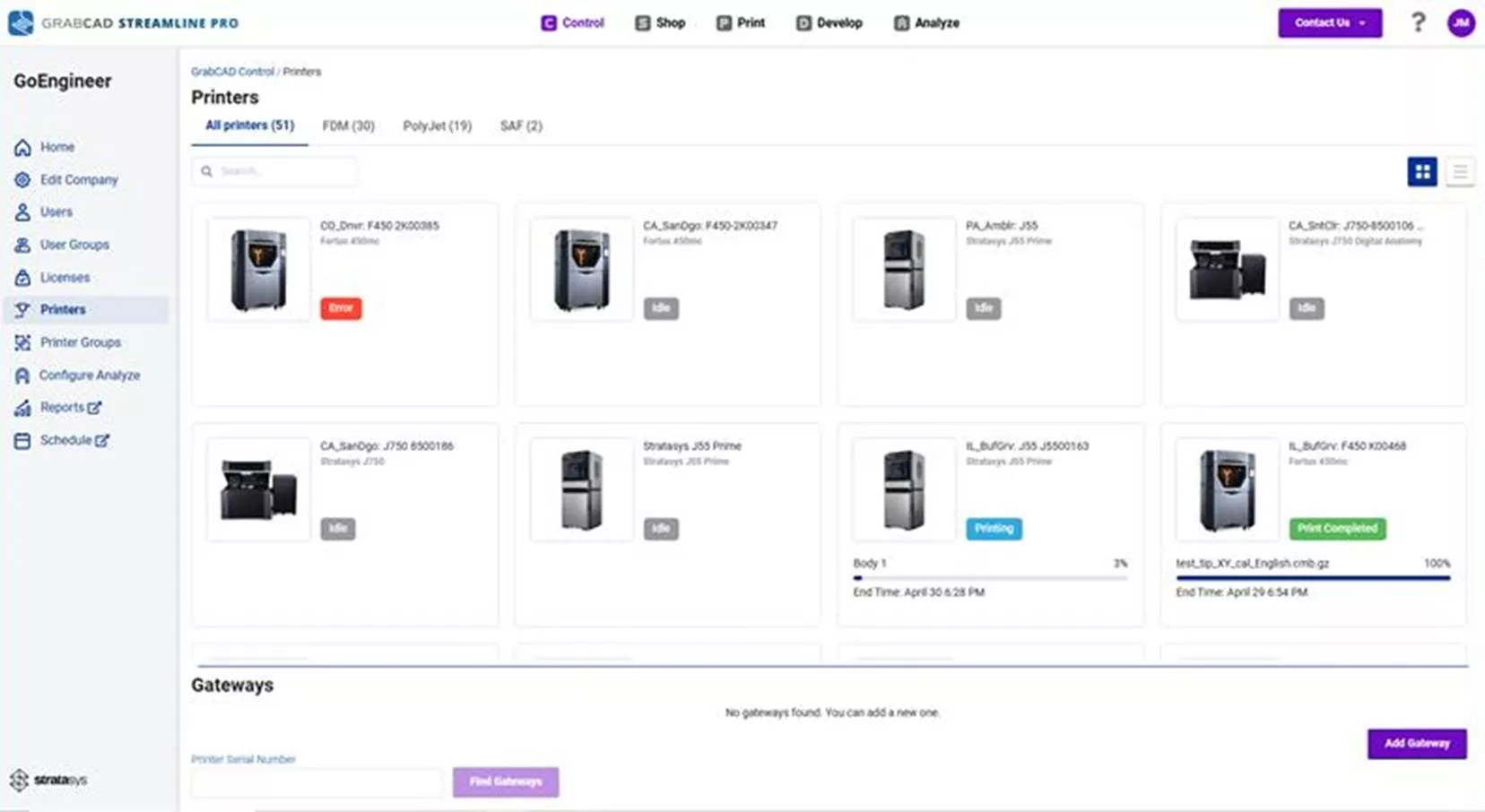

Queue Oversight

The Control module is your centralized dashboard for managing day-to-day print production. Whether you're running a handful of machines or a full printer lab, Control offers real-time visibility into machine status, build progress, and job queues.

I especially like that it allows manual queue adjustments and sends alerts for key events like job completion or errors. This means I can actively respond to issues without physically being at the printer (critical when managing tight deadlines or overlapping shifts).

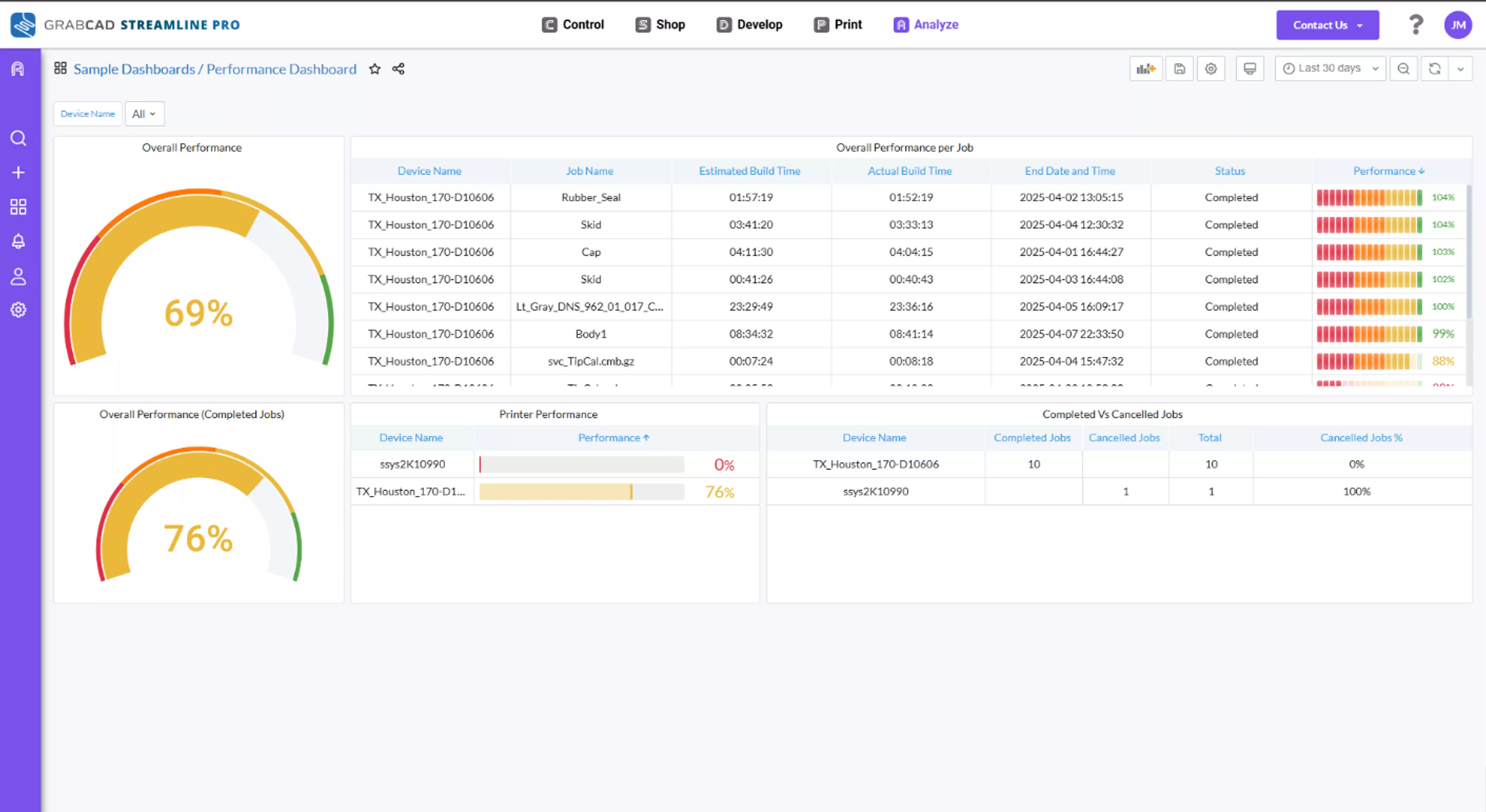

Data Insights

With Analyze, you can transform machine utilization statistics into actionable insights. It gives you easy access to key performance metrics like machine uptime, material consumption, print success rates, and throughput.

This visibility helps identify areas for improvement. For example, I’ve used Analyze to spot underused machines, estimate material reorders, and flag printers that may need service based on performance trends.

Access Management

Cloud computing solutions can provide significant value for companies that do not want to maintain their own IT infrastructure or that want to empower their employees to work remotely. But for some, cloud connectivity is not operationally possible.

The Shield hardware handles access control and file protection, making it easy to keep your print operations secure, especially important if you're handling proprietary designs or operating in a regulated space, like an air-gapped environment.

With Shield, you can define who is allowed to submit jobs, adjust print settings, or access specific machines. It supports features like secure job release, role-based permissions, and full activity logging for audit readiness.

Enterprise Integration

For teams that already use ERP, PLM, or MES tools, the Connectivity API allows seamless integration with existing systems. That means build requests can come straight from your design or production platforms, and print data can be fed back automatically for reporting.

If you're looking to bring order and efficiency into your Stratasys print operations, GrabCAD Streamline Pro is the perfect platform to build on. It’s modular, scalable, and ready to grow with your business, whether you’re managing one 3D printer or a full fleet.

Interested in learning more about Streamline Pro or other GrabCAD Print solutions? Contact us.

Related Articles

How 3D Printing is Helping Manufacturers Fight Back Against Tariffs

Economic Change in Manufacturing Demands a New Approach by Leveraging 3D Printing

DICOM-to-3D Print Medical Models: Methods Used to Compare Accuracy

Which Technology is Best for 3D Printing Miniatures?

About Simon Pinter

Simon Pinter is a Manufacturing Solutions Application Engineer at GoEngineer

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.