How Wikk Industries is Using DriveWorks to Bridge the Accessibility Gap

Table of Contents

If you've ever used an automatic entrance button when walking into a building, you've experienced the kind of product Wikk Industries creates. Based just outside Milwaukee, this family-owned manufacturer designs and produces code-compliant accessibility solutions that help bridge the accessibility gap.

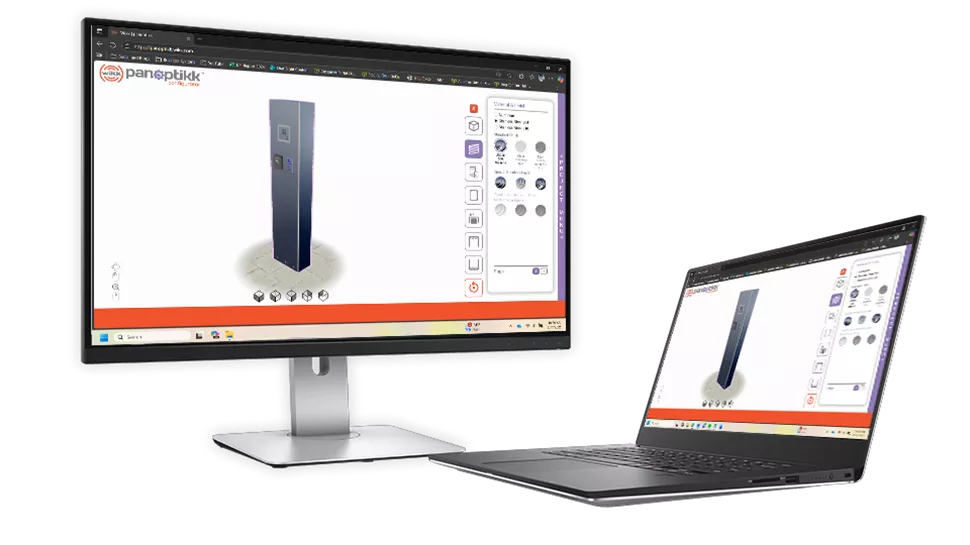

In 2025, Wikk launched panoptikk, a 3D product configurator powered by DriveWorks Pro, to change how customers interact with their products. We spoke with Kimberly, Design Engineer and DriveWorks administrator, and Brian, Wikk's president, about what inspired the project, the impact they've seen, and what's next for their automation platform.

Why DriveWorks?

For many, automation means massive assembly lines or high-volume production. But for Wikk, it started as a practical solution for a small engineering team with a growing workload.

Much of Wikk's design work was repetitive—revising similar components or re-creating drawings from scratch. As Kimberly explained, DriveWorks helped them reclaim time and put it toward innovation.

"We're a small company with a small engineering team. A lot of what we were doing was repetitive—either starting from scratch for custom drawings or finding a previous one and modifying it. DriveWorks really helped streamline that."

Now, instead of spending hours redrawing parts, Wikk's engineers generate models and drawings in minutes.

"You're not drawing things from scratch anymore. This is something that's built that you can now use. You can at least get 80% of the way there."

That speed lets the team focus on what they do best—designing solutions that make public spaces more accessible.

A Confident Choice

When it came time to choose an automation platform, the decision was straightforward.

As Brian put it, "From my perspective, we had to pick a horse to ride. I looked at the product roadmap and thought DriveWorks had the most compelling strategy. It was the right choice."

That confidence came from the product's flexibility and from knowing Wikk could grow at its own pace.

From Solo to Pro

Wikk started with DriveWorks Solo around 2021, using it internally to automate repetitive design tasks and build confidence in rule-based design. After a few years, they'd outgrown Solo's capabilities and were ready to expand. With Kimberly's experience writing rules in DriveWorks Solo, the path forward was clear.

"The big push to upgrade was our goal of having an online configurator—something our customers could use directly. That's what drove the move from Solo to Pro."

The transition to DriveWorks Pro was a major step, taking what Wikk had built internally and putting it on an external-facing website. Kimberly led the implementation from start to finish, and when challenges came up, she worked closely with GoEngineer's DriveWorks team, especially Guy Wilhite.

"Guy and Kat [GoEngineer Project Manager] were great. They really held my hand through the implementation, helping me figure out how to approach each challenge one step at a time. Guy didn't just tell me what to do - he made sure I understood why something needed to be set up that way, so I could handle it myself next time."

That partnership made a real difference. Kimberly built panoptikk herself, but having someone with deep DriveWorks experience to lean on gave her the confidence to tackle complex logic and see the project through.

"I honestly don't think I could've finished panoptikk without his help. It was invaluable having someone who's seen so many DriveWorks projects and knows what works and what doesn't."

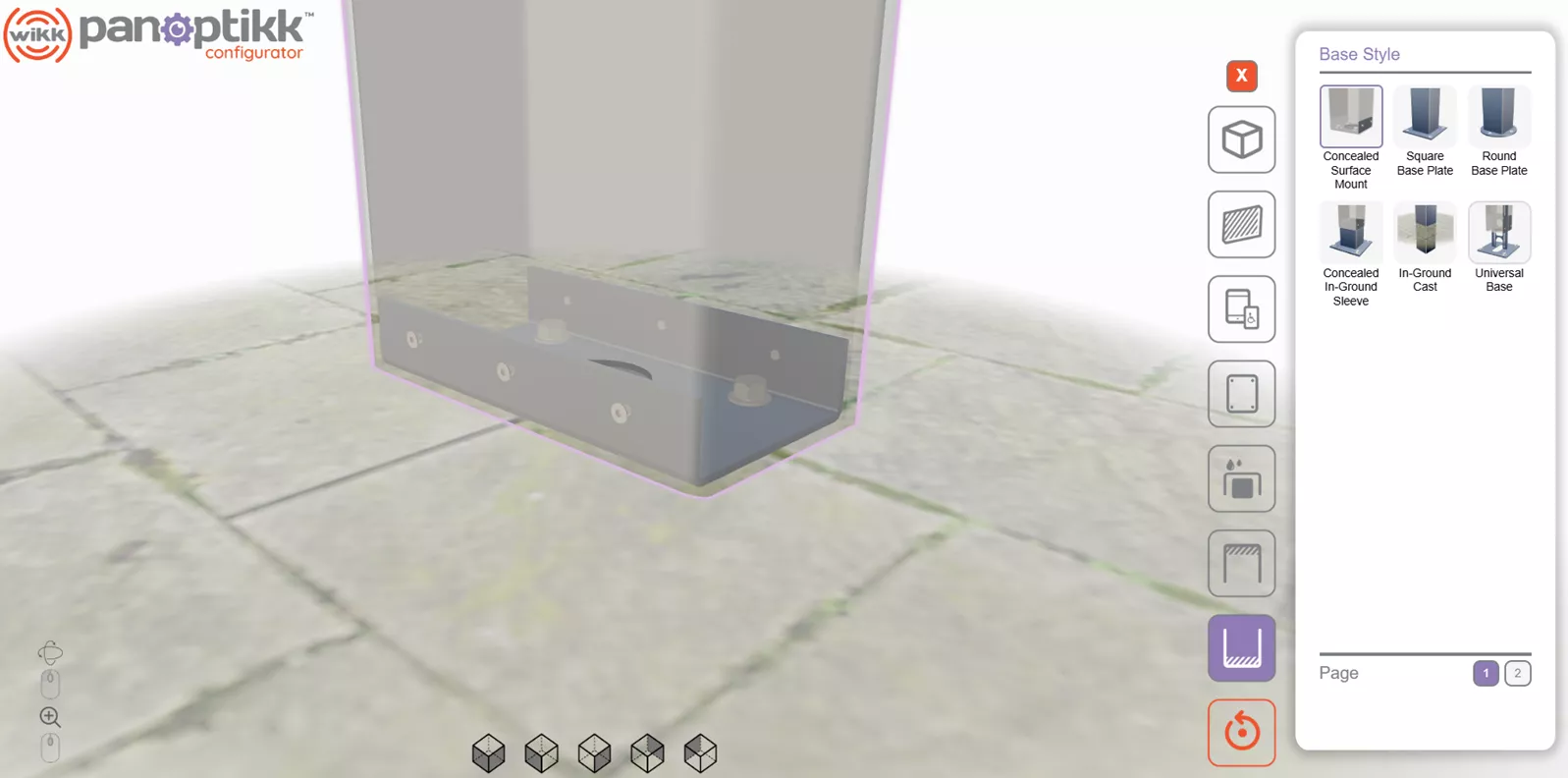

Introducing panoptikk

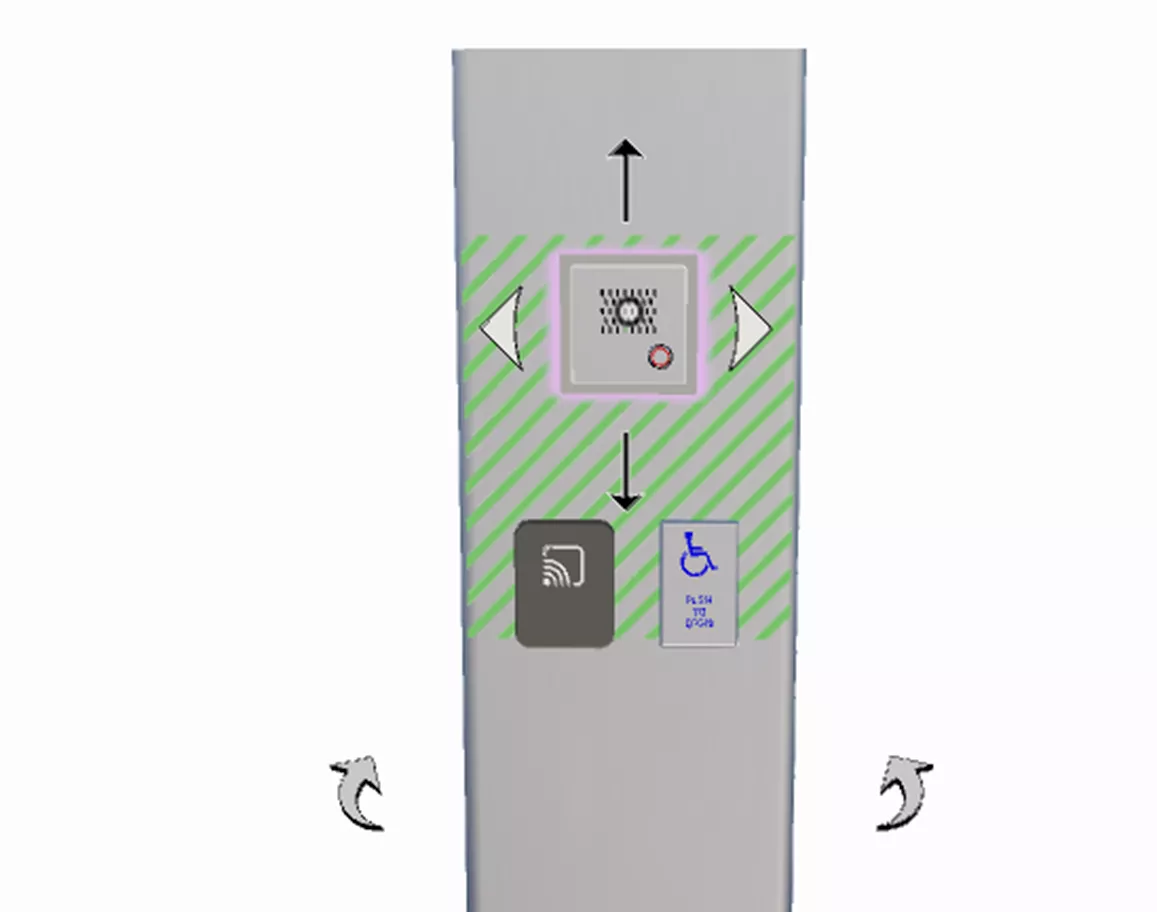

panoptikk brings a new level of accessibility, not just in Wikk's products, but in how customers can explore them. The configurator lets users visualize and customize entrance designs in 3D while automatically ensuring ADA and code compliance. For Brian, this was one of the most important features.

"We allow customers to visualize exactly what they're building. And, we built in ADA compliance and interference detection, so you can't design something that is not code compliant."

Architects, a key audience for Wikk, are using the configurator to understand the company's capabilities in a more hands-on way. The result is faster design reviews, fewer mistakes, and more confidence in specifications.

What started as an engineering tool has become a marketing and sales asset, opening new conversations with customers.

"Customers have told us, 'Oh, I didn't even know you could do that.' It's a way to show what's possible and educate people about our products."

That visibility is already having an impact on the business. Within three weeks of launch, Wikk has seen an increase in sales tied directly to panoptikk.

What's Next for Wikk

panoptikk is just the start. Wikk is looking to expand the configurator to include pricing and quoting capabilities, giving customers a smoother experience from design to order.

"We're not using it right now for quoting, as in giving pricing out. I do want to build in internal quoting parameters so that when someone has created a specification, we also generate all that information, and we're ready to send out a quote if needed."

The team is also exploring tighter integration with SOLIDWORKS CAM and deeper analytics using the data gathered through each configuration.

"We connected it to a database. So every time someone creates a specification, I'm taking the data that we need, and we'll be able to look at trends, what people are selecting, and KPIs."

As they keep expanding what the platform can do, Wikk is focused on using DriveWorks for innovation, not just automation. This is one of Brian's biggest sources of pride.

"We've gone from reliable to innovative. panoptikk shows our customers that we're not stagnant. We're willing to push boundaries."

Wikk's success with DriveWorks comes from more than clever rule writing or automation. It's about collaboration, both internally and with their customers.

"We built this with our customers, not just for them. Two of the people who helped shape panoptikk work for our largest customers."

Questions?

Contact us today to learn more about how DriveWorks can transform your business.

Related Articles

Compare DriveWorks Packages: Features in DriveWorksXpress, Solo & Pro

Accelerating the Sales Cycle with DriveWorks CPQ

DriveWorks CPQ - Enhancing Collaboration Between Sales and Engineering

Everything New in DriveWorks 21: Rules, Integration, 3D Previews & More

About Nick Sweeney

Nick Sweeney is a Marketing Specialist with GoEngineer with a focus on software solutions. Nick graduated from The Ohio State University in 2018, completing internships with CATI (now GoEngineer) and DriveWorks Ltd. Before joining the Marketing team, Nick spent 3 years in pre-sales with CATI, giving product demonstrations, leading technical discussions, and creating technical content.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.