SOLIDWORKS CAM Features & Allowable Operations

The core of SOLIDWORKS CAM is its feature recognition engine, but these features are not the same extrudes and revolves we are used to with SOLIDWORKS. Let's take a tour through the feature types and allowable operations used by SOLIDWORKS CAM.

In this article we'll cover the following 10 SOLIDWORKS CAM features as well as their allowable operations:

- Face features

- Open pocket

- Slots

- Corner slots

- Boss

- Hole

- Open profile

- Engraved feature

- Curve feature

![]() Related Video >> SOLIDWORKS CAM and CAMWorks: What's New in 2021

Related Video >> SOLIDWORKS CAM and CAMWorks: What's New in 2021

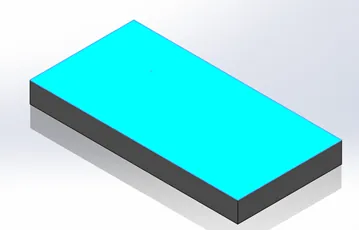

Face Features

A Face Feature is an open area to be cut using a Facemill. SOLIDWORKS CAM moves the tool parallel to the selected face past the boundaries of the feature. Face features can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

Open Pocket

An Open Pocket is an area to cut that is open on all sides. This is similar to a face feature but includes islands/ bosses or an area that you want to work around. Open pockets can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

A Pocket is a recessed area where none of the sides are open to air. The tool will stay within the edges of the feature. Pockets can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill, Thread Mill, and all Hole Machining Operations

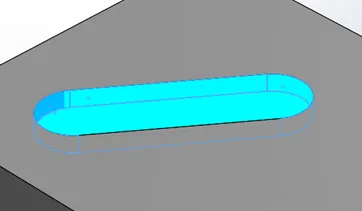

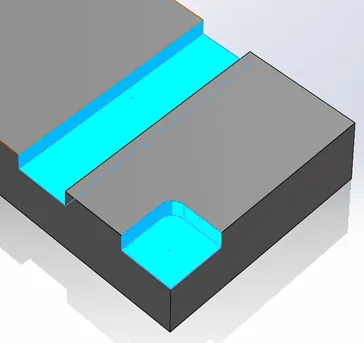

Slot

A Slot is a recessed area with one side open to air. SOLIDWORKS CAM will detect the open side and allow the tool to travel beyond the edge to ensure the feature is fully cut. Slots can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

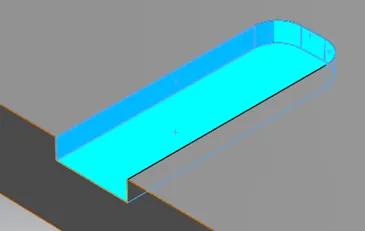

Corner Slots

Corner Slots are recessed areas with two sides open to the air. SOLIDWORKS CAM will identify the open sides and allow the tool to travel beyond the edges of the feature on the open sides to ensure the geometry of the feature is fully cut. SOLIDWORKS CAM distinguishes between Rectangular and Irregular shaped corner slots. Corner slots can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

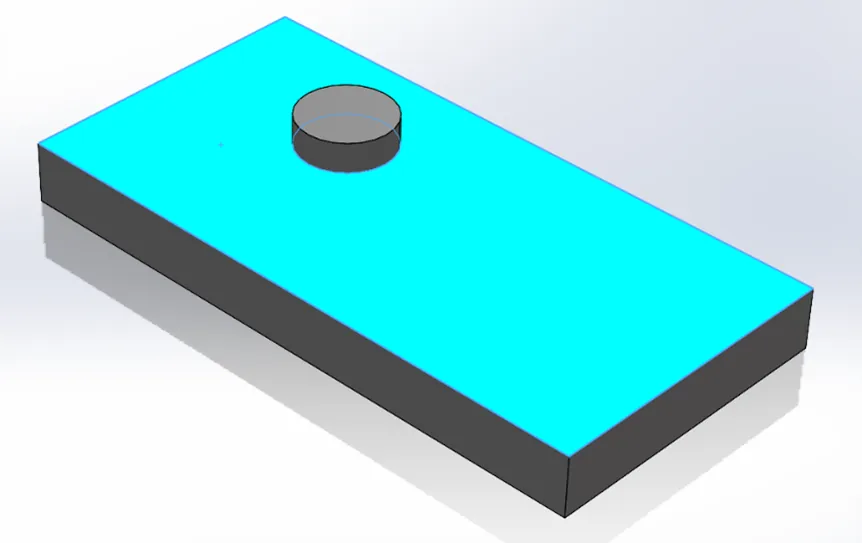

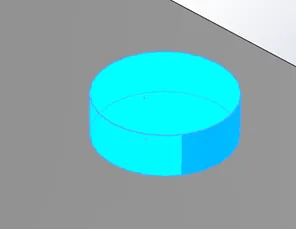

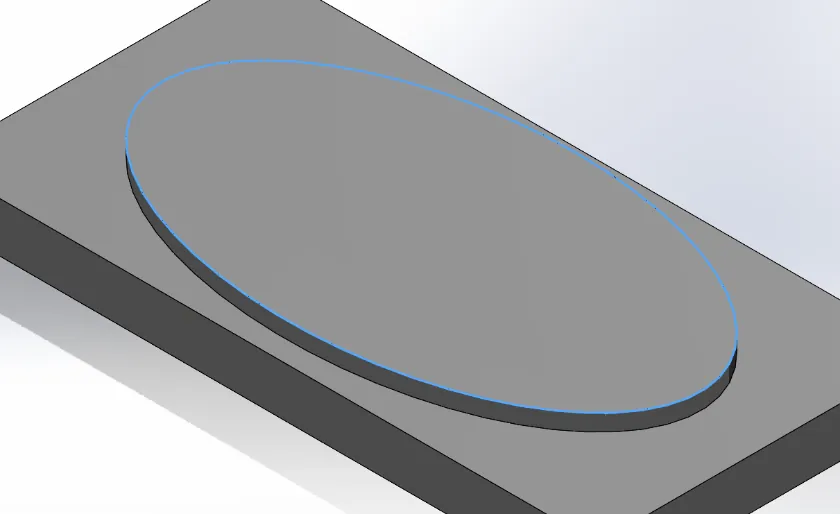

Boss

A Boss is a raised area of material to be cut around. SOLIDWORKS CAM distinguishes between Rectangular, Circular, Irregular, and Obround shapes. Bosses can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Contour Mill, Thread Mill

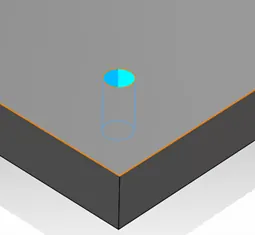

Hole

A Hole is a round recess to a depth or through the stock using point-to-point tools. SOLIDWORKS CAM recognizes blind and through holes. Holes can be defined by faces, edges, or circular sketches.

Allowable operations: Center drill, Drill (including peck), Countersink, Bore, Ream, Tap, Rough Mill, Contour Mill, Thread Mill

Open Profile

The Open Profile feature allows the tool to follow part edges or sketch lines. The tool will be offset from the edge or sketch line by the radius of the tool. This feature is commonly used to make a cut along the side of a part. This feature can be used on open, non-intersecting edges and sketches that are parallel to the current Mill Part Setup.

Allowable operations: Contour Mill

Engrave Feature

With Engrave Feature, the tool center will follow the selected sketch entities, which can include edges, lines, arcs, splines, and text objects. Sketches can be open, closed, or self-intersecting.

Allowable operations: Contour Mill

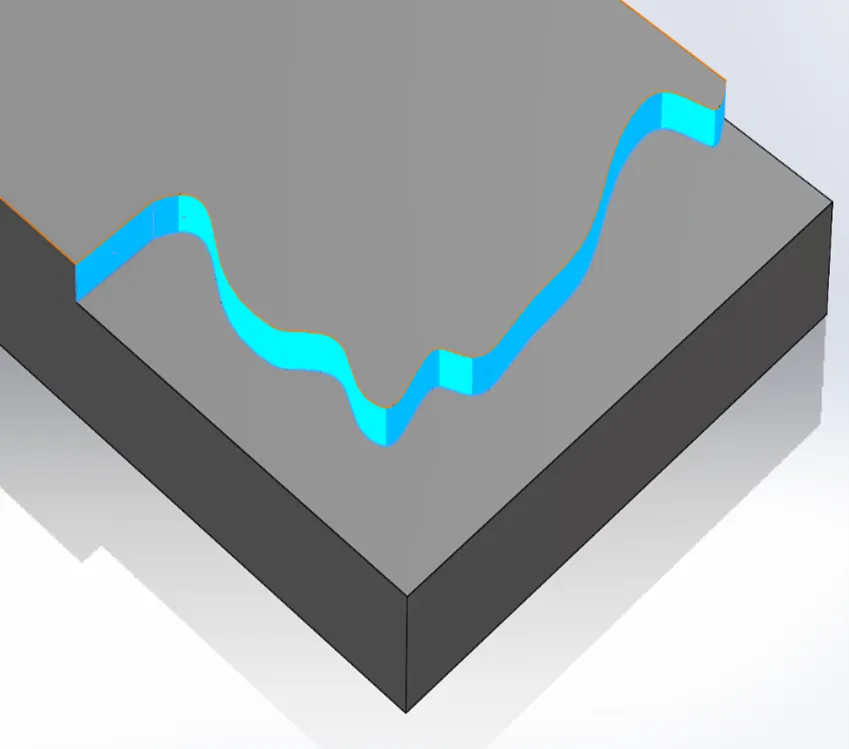

Curve Feature

With Curve Feature, the tool center will follow the selected 2D or 3D sketch, edge, or curve in three dimensions. This is often useful for chamfers. Selected entities can be open, closed, or self-intersecting.

Allowable operations: Contour Mill

Learn More About SOLIDWORKS CAM

SOLIDWORKS CAM & CAMWorks CommandManager Icon Reset

SOLIDWORKS CAM Overview: Standard VS. Professional

About Martin Bucholz

Marty has been in the manufacturing industry since around 2000, doing a bit of everything, Tool & Die machining, assembly work, inventory control, shipping and receiving, even sweeping the floors. He started using SOLIDWORKS as a product designer in 2007 for Cast Aluminum solutions (formerly a division of Watlow) designing customized heating solutions for food service, medical, and semiconductor industries. Then in 2014 he moved over to the VAR side of things and has been doing tech support and training for SOLIDWORKS, SOLIDWORKS PDM and now SOLIDWORKS CAM and CAMWorks. Outside of the office Marty is an avid gamer from board games to video games, even helping to plan and run a local Tucson gaming convention. When he is not doing that you can find him walking dogs at the Pima County Animal Care Center.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.