SOLIDWORKS Simulation Submodeling Advantages and Limitations

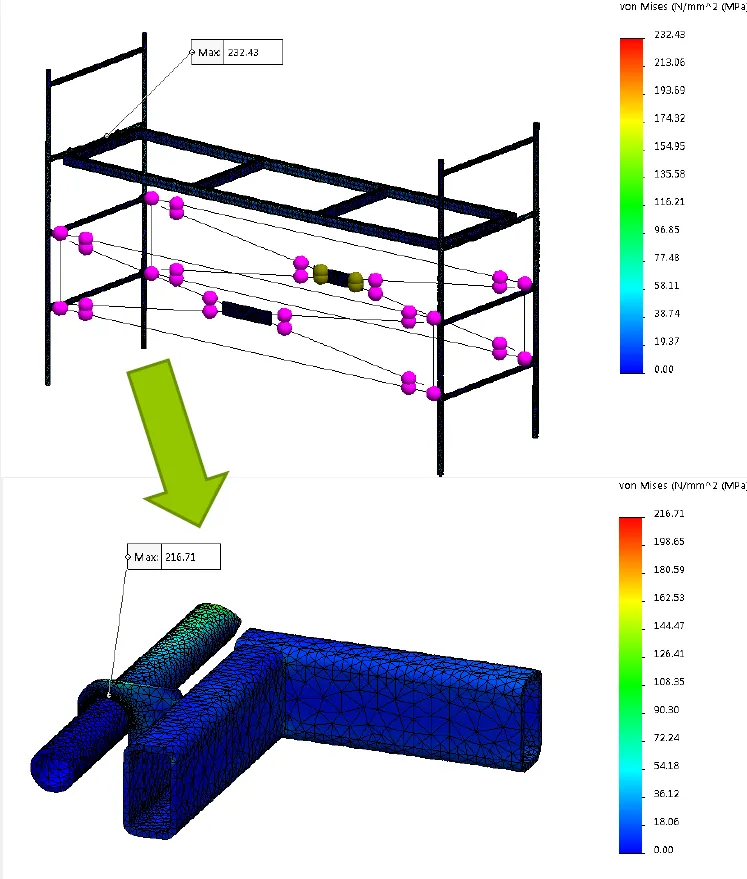

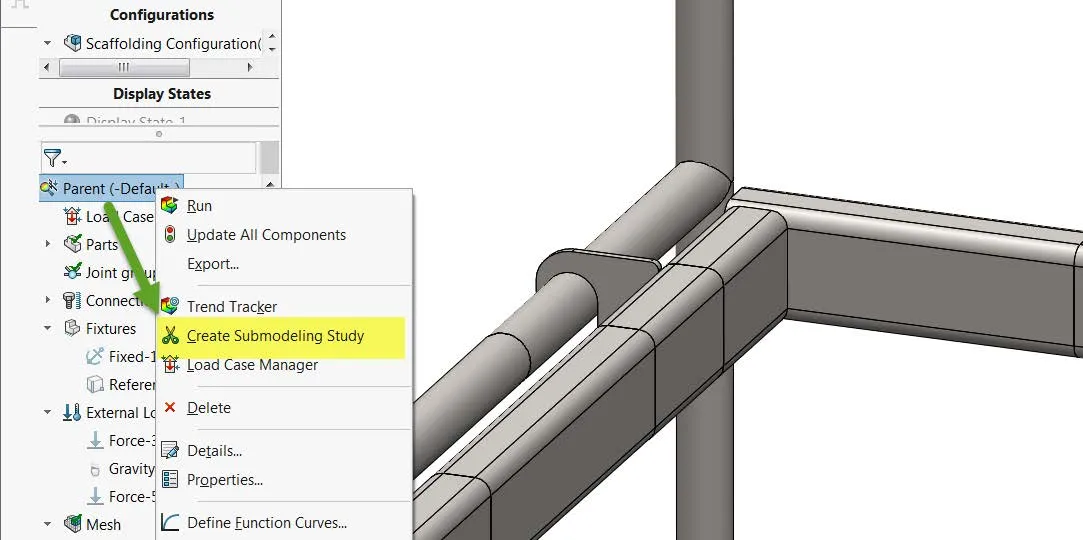

Submodeling in SOLIDWORKS Simulation is a powerful technique to capture boundary conditions from a parent static study and run a more refined study on a much smaller area as a “Submodel” study. However, there is a stringent list of requirements for this to work as follows:

Submodeling Advantages

- Submodeling can help transfer complex global loads from the entire structure to local regions and obtain accurate stress in a local region.

- Enables to experiment with different designs for the region of interest.

- Helps in demonstrating the adequacy of mesh refinements.

Submodeling Limitations

- Parent study must have more than 1 body since there is no advantage in using sub modeling studies on a single body.

- By default, all bodies inside the sub modeling study will be treated as solids (meshed as solids). See help for more details on how you can have shells and beams inside a sub-model study.

- Parent study cannot have a “No Penetration” contact condition for all bodies.

- Parent study cannot have all the bodies connected by connectors (bolts, pins, etc).

- Not available for 2D study

- Not available for Pure beam-beam bonded contact.

I hope you found this article describing the advantages and limitations of SOLIDWORKS Simulation submodeling helpful. Learn more about SOLIDWORKS Simulation below.

Expand Your SOLIDWORKS Simulation Skillset

SOLIDWORKS Simulation Gauss Points, Nodal, and Element Stress

Troubleshooting SOLIDWORKS Simulation No Penetration Contact Sets Recommendations

Changing Units and Number Formats in SOLIDWORKS Simulation

SOLIDWORKS Simulation Tips: No Penetration Contact Set Setup

A Guide for Using Bearing Connectors in SOLIDWORKS Simulation

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.