How to Machine Large Hole Chamfers in CAMWorks

Cutting chamfers, where the size of the chamfer is much larger than the tool used, presents a unique set of problems. Once the hole becomes larger than the tool, the automatic chamfer abilities of the CAMWorks ContourMill operation cannot be used.

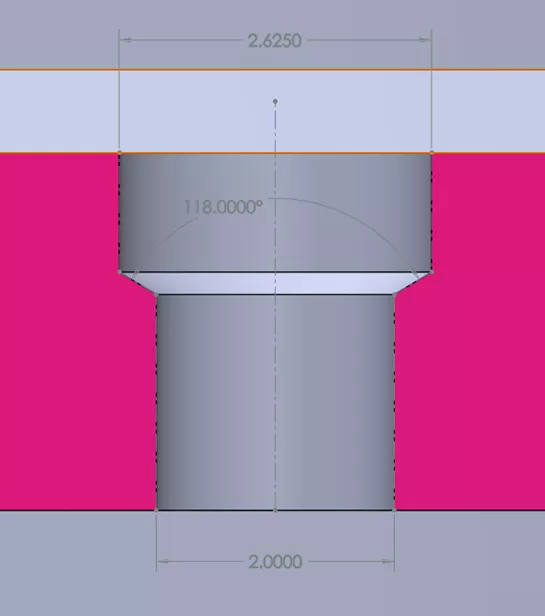

Under these circumstances, there are several ways of cutting the large chamfer, using a ContourMill or a Multiaxis (in 3-axis mode). This example uses the shape below to illustrate these methods.

This illustrates the use of a pocket (the use of a MultiStep hole is also possible).

Using a Taper Feature and a Countersink Tool

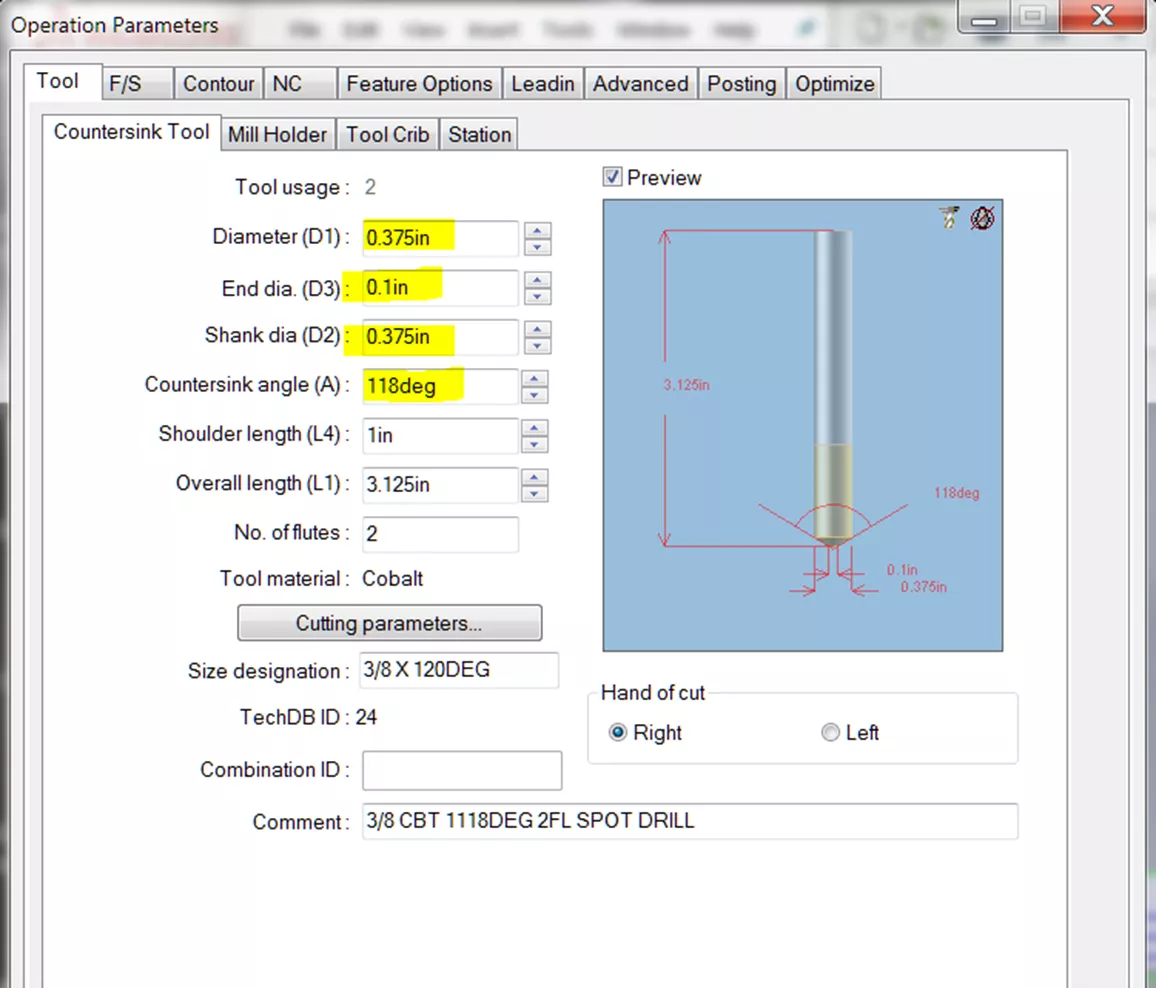

The countersink tool uses the bottom (or End) diameter (D3 below) to calculate the toolpath, so specific values have to be set to account for this when cutting a tapered feature.

- Create a circular pocket using the top of the chamfer. Make it a taper feature. In this example, the taper is 59deg.

- Generate a ContourMill and adjust its parameters. The most important parameters are the tool used, the depth of first cut, and the allowance.

- Define the tool as a countersink.

- Side Allowance must be set to a negative value:

Set this allowance to (D3÷2) - (D1÷2). This is (-.1375) for the tool shown above. - The first cut must be set to ((D1÷2) - (D3÷2)) ÷ tan(angle A÷2).

For the tool shown above, this is

(D1÷2) – (D3÷2) = 0.1375

(0.1375) ÷ tan(59°) = 0.0826

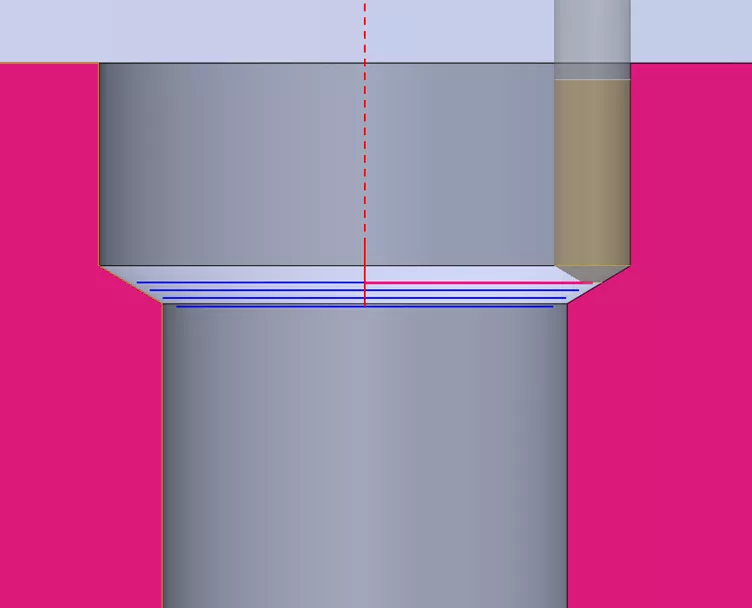

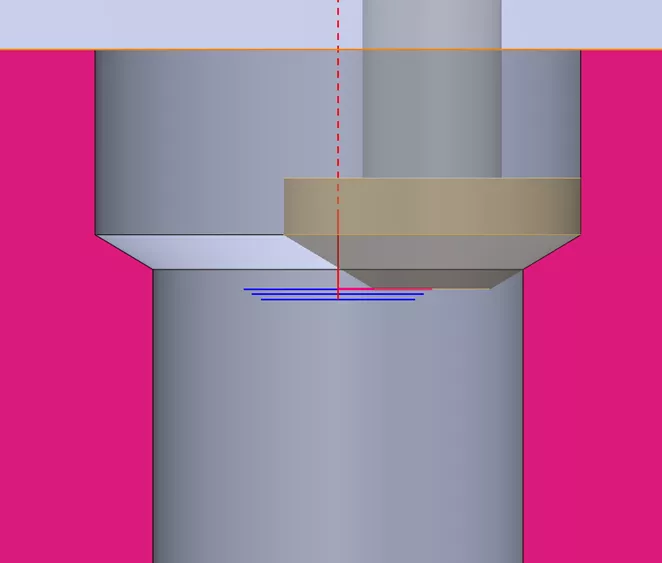

The resulting cut, showing the tool at the edge of the pocket:

Note the position of the tool relative to the chamfer and the bore.

Using a Taper Feature and a Taper End Mill

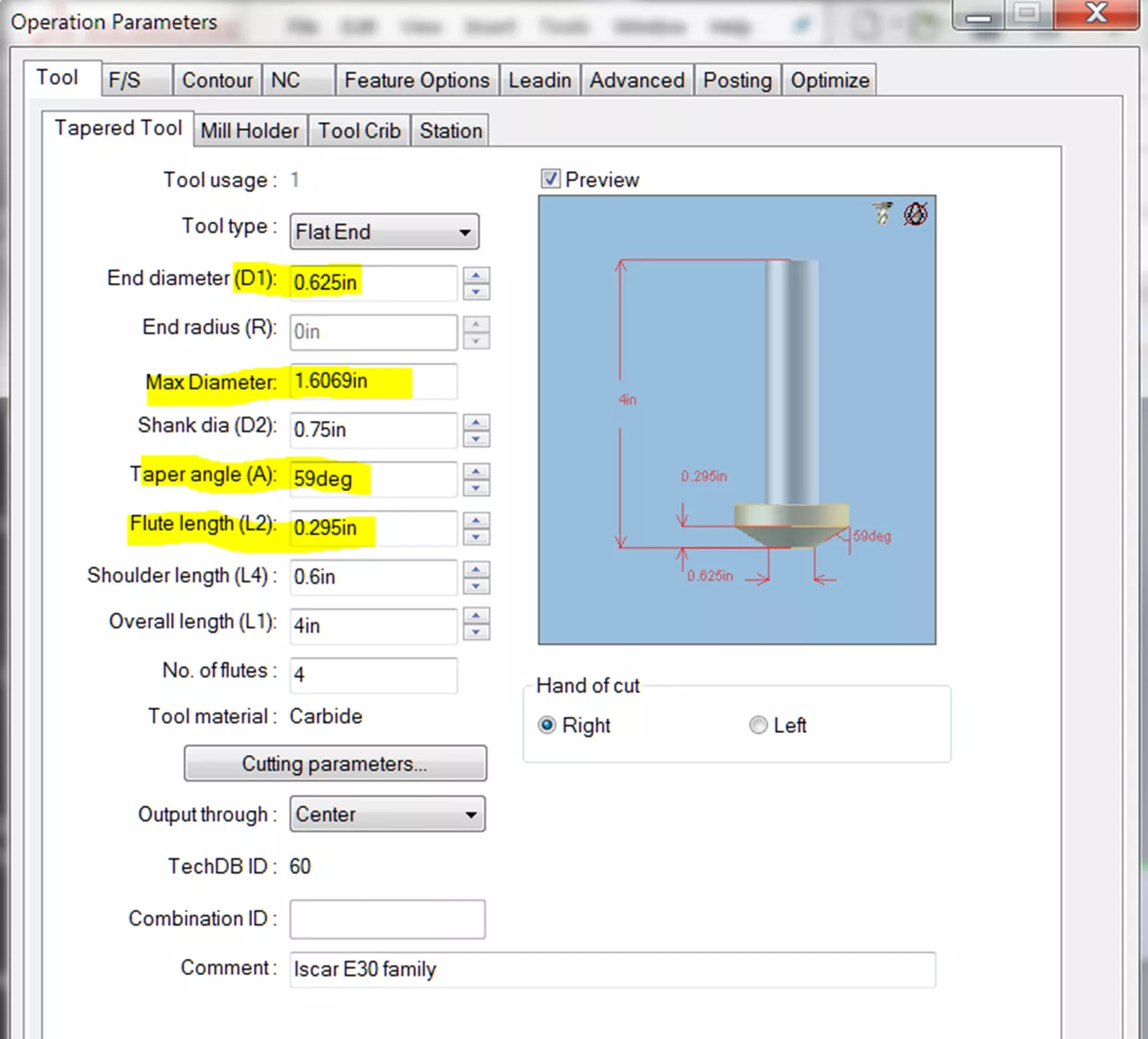

The taper end mill uses the diameter of the body to calculate the toolpath. The specific values are different than when a countersink is used.

- Describe the same circular taper pocket as above. The feature has to have a depth larger than what will become the first cut.

- Generate a ContourMill and adjust its parameters.

- Describe the tool as a taper end mill. Note that the system calculates the maximum diameter based on the Taper angle (A), the End diameter (D1), and the Flute length (L2):

- Because the taper end mill calculates using the Max Diameter, the side allowance becomes 0, to place the edge of the tool at the edge of the circular opening.

- The first cut amount becomes

((MaxDiameter÷2) – (D1 ÷2)) ÷ tan(Angle A)

In the example above, this becomes

(1.6069÷2) – (0.625÷2) = 0.4909

0.4909÷tan(59°)=0.29499

The resulting cut, showing the tool at the edge of the pocket:

Using a MultiAxis Operation

This involves using the same taper end mill as b. and setting the axis control to 3-axis.

Gouge protect should be used for the surfaces above the taper being cut, with the action taken to Move Tool Away, To Cut Center.

Remove Gouged Positions can also be used.

Depending on tolerance/finish requirements, the side allowance and first cut can be adjusted by a small amount to avoid the tool engaging the sides of the bore. Machine compensation is also available to properly size the cut.

Related Articles

What Is Feature-Based CAM and Why Is It Important?

7 CAMWorks Time-Saving Techniques

CAMWorks SOLIDWORKS OEM Installation

About Krystal Petersen

Krystal Petersen is a SOLIDWORKS Technical Support Engineer based out of Auburn Hills, Michigan. Krystal studied Product Engineering at Oakland Community College and has earned her CSWA and CSWP Certifications. She joined the VAR channel in 2015 with DASI (now GoEngineer). Krystal is a huge fan of Star Wars and likes to spend her off time fishing and camping.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.