Metal AM's Competitive Edge: BLT, BYD, and the Integrated Body Structure That Redefined Supercar Performance

In September 2025, BYD’s Yangwang U9X supercar shattered expectations, setting a world top-speed record for production vehicles at 308.33 mph and clocking a blistering 6:59.157 lap time at the Nürburgring Nordschleife. It’s an incredible feat of electric propulsion, but the unsung hero of this achievement isn’t just the motor; it’s the frame holding it all together. The U9X’s success was built on a foundation of metal additive manufacturing provided by Bright Laser Technologies (BLT), proving that 3D printing is no longer just for prototyping; it is a production-grade powerhouse.

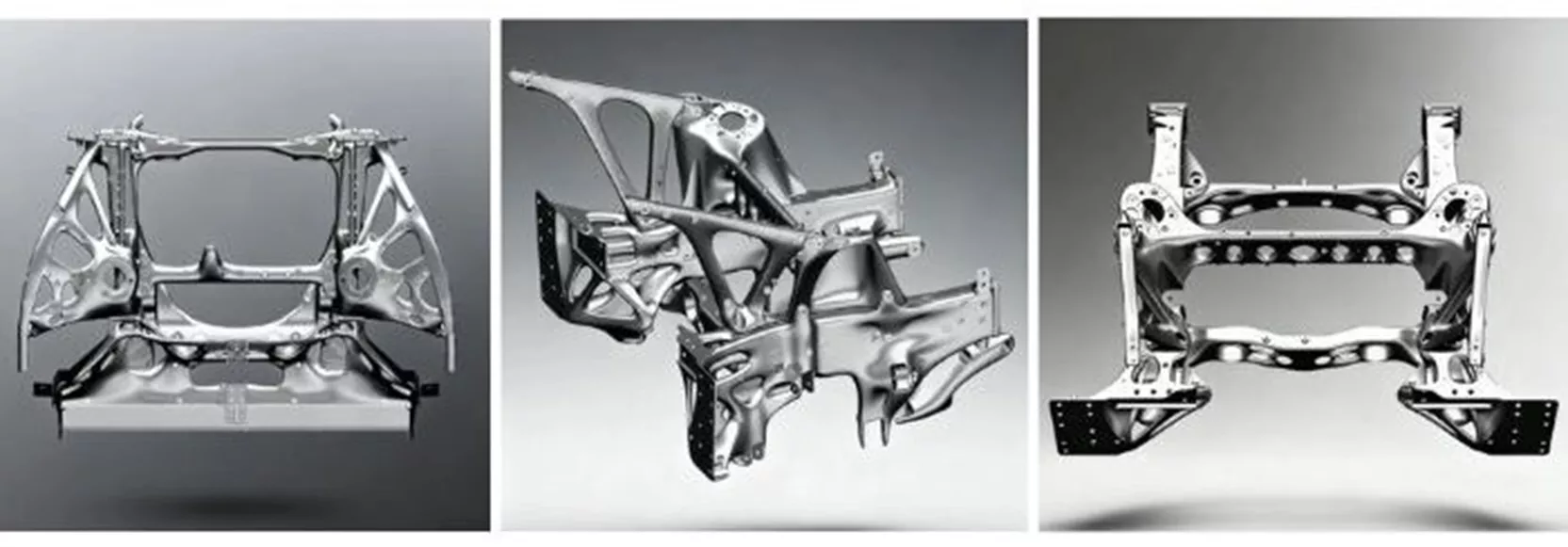

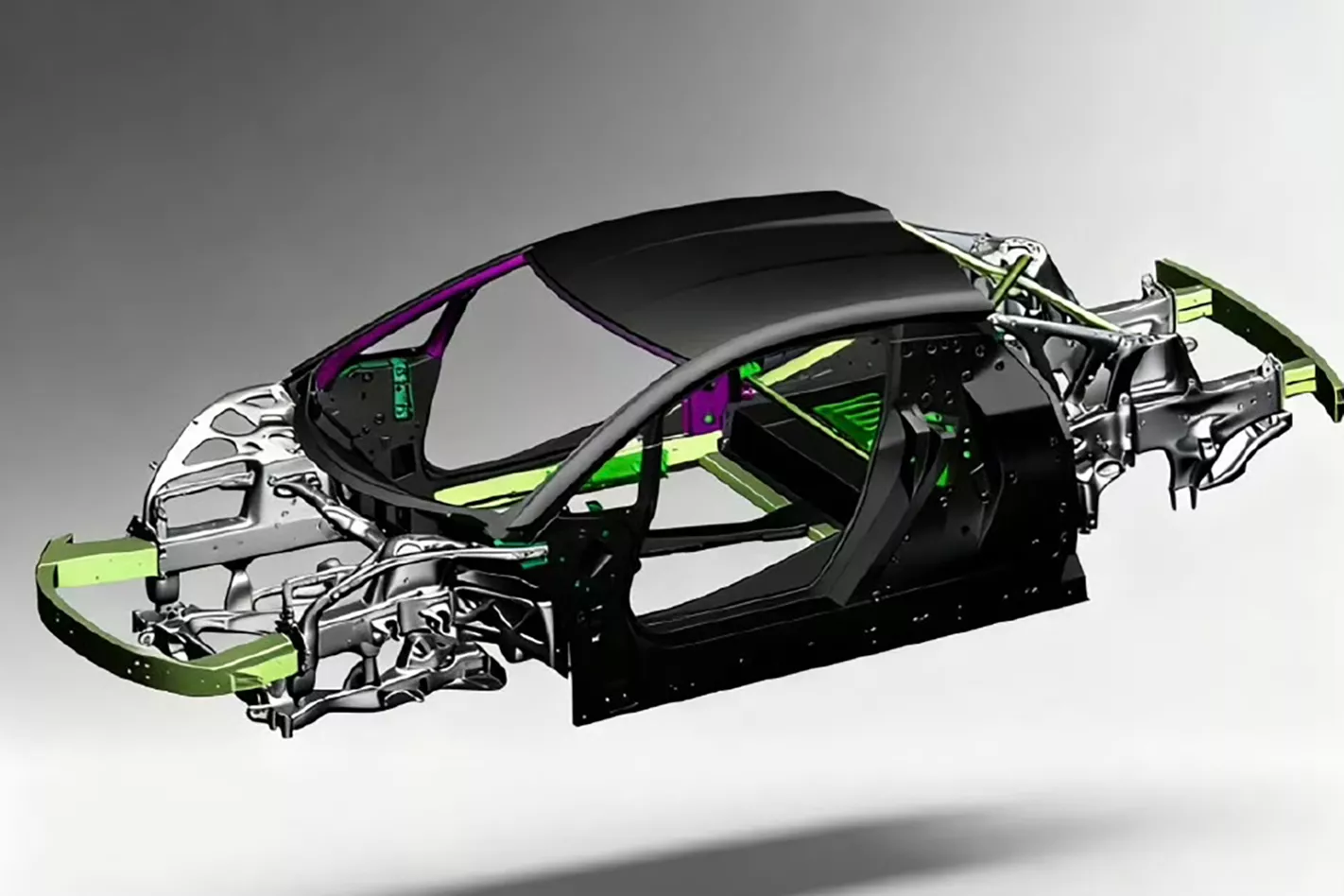

The "HyperCell" Frame

To handle speeds approaching 310 mph, traditional casting methods weren't enough. The Yangwang team turned to aerospace design principles, utilizing a technique known as multidimensional surface parametric modeling. This allowed for smooth, continuous transitions across complex curved surfaces, a geometry nearly impossible to achieve with conventional tooling.

The result was the Printing HyperCell structure: a honeycomb-like, integrated body chassis that balances extreme lightness with immense strength.

200% Increase in Torsional Stiffness - Using topology optimization, the chassis features internal hollow chambers and reinforcing ribs that distribute stress far more efficiently than solid structures.

30% Weight Reduction - By using a high-strength aluminum alloy developed specifically for this project (boasting three times the yield strength of conventional cast aluminum), the vehicle shed critical pounds without sacrificing safety.

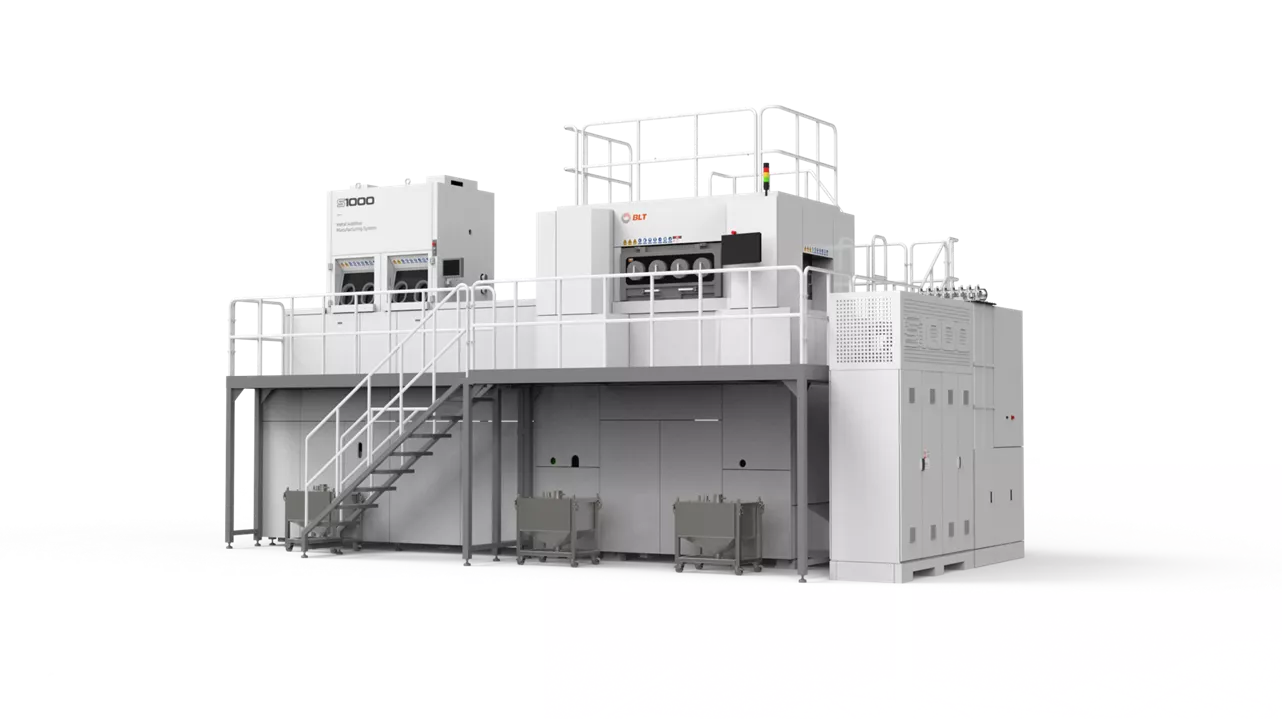

Precision at Scale - The BLT Advantage

The production of the U9X’s body and components utilized BLT’s large-format metal 3D printers, specifically the BLT-S1000, BLT-S615, and BLT-S815.

These machines delivered precision that rivals aircraft engine components. By using laser selective melting and advanced process compensation algorithms, the team achieved:

- Dimensional deviation within ±0.5 mm for over 90% of the printed surfaces.

- Key mounting surface tolerance within 0.1 mm.

- Integrated functionality. Beyond the frame, BLT printed brake calipers that were 20–30% lighter and featured integrated internal oil channels, eliminating assembly steps and potential failure points.

Bring World-Record Technology to Your Shop Floor

The Yangwang U9X is a testament to what happens when engineers are given the freedom to design for performance rather than manufacturability constraints. BLT’s technology didn’t just make this car faster; it made a design previously thought impossible into a repeatable, production-ready reality.

As the exclusive reseller of BLT printers for North America, GoEngineer is proud to bring these same capabilities to the U.S. and Canada. Whether you are in automotive, aerospace, or defense, the ability to print large-scale, high-strength metal parts with complex internal geometries is a game-changer.

The U9X has set the bar. Now, it’s time to see what you can build.

Interested in learning more about how metal additive manufacturing can transform your production line? Contact GoEngineer today to explore our lineup of BLT 3D printers.

More 3D Printing News

Who’s Printing the Future? Inside 10 Companies Using BLT Metal AM

From Hobby to Heavy Duty: Why High-Performance Polymers Matter Now

Antero 840CN03 Deep Dive: Strengths, Applications, Limitations & More

DyeMansion Powershot C Consumables Stream: How It Works

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.