SOLIDWORKS CAM 2024: Dynamic Highlight, Output Options, Tool Select Filter, & More

Lots of great enhancements have been added to the latest version of SOLIDWORKS to simplify your CNC machining setup in SOLIDWORKS CAM 2024. (Astute observers may have seen some of these changes in the later Service Packs of SOLIDWORKS 2023.) Let’s get started with these sneaky additions.

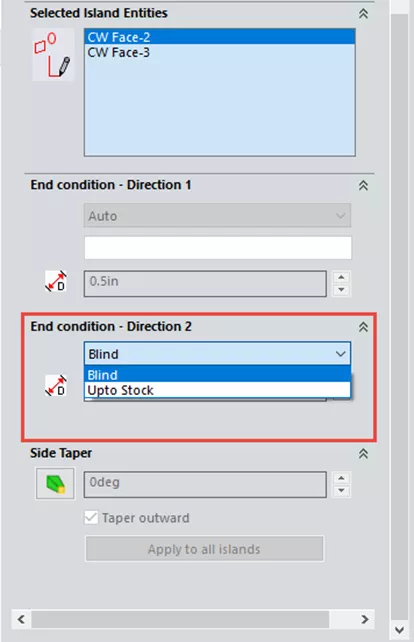

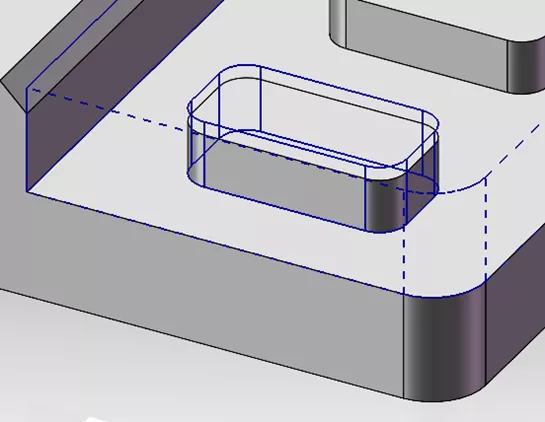

Island End Conditions

In SOLIDWORKS CAM 2024, users can now add material on top of Islands that are of different height than the 2.5 Axis Feature Depth. When creating a Machinable Feature, the new ‘Direction2’ for Island Depth can be set to Upto Stock, left flat topped, or specify added material. This is a great time saver as no extra Machinable Feature is needed to create the same target geometry.

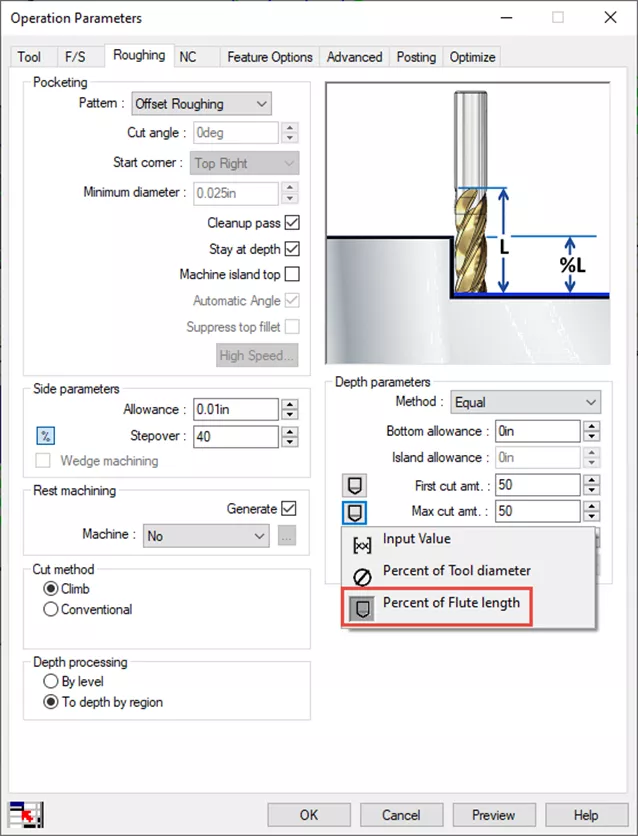

Depth of Cut - Percent of Flute Length

When defining the First and Max Cut Depth Parameters, these now have Percent of Flute length as a depth option, allowing even more flexibility to match your machining processes. This enhancement is a personal favorite.

Linked Contour Mill Lead-In/Out

This next update streamlines how users can apply consistent Lead-In and Out settings for Contour Mill Operations. If there are multiple Contour Mill Operations in a Part Model, the Apply Lead In/Out to all setting will propagate to Linked Contour Mill Operations. No extra Operation Modification is needed in SOLIDWORKS CAM 2024.

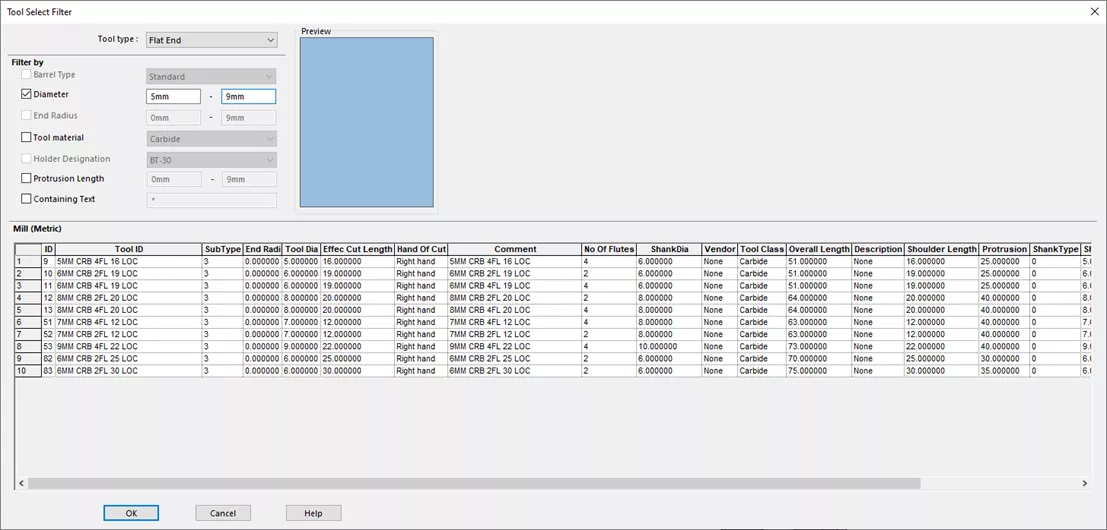

Tool Select Filter

When searching for different Mill Tools, re-size the Tool Select Filter window to show even more information to make it that much easier to get the right tool for the job.

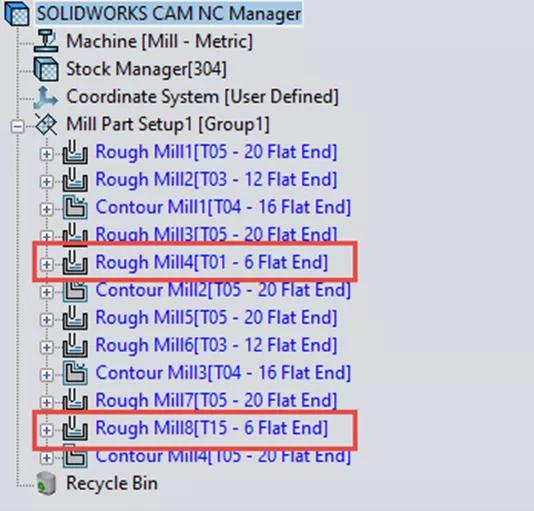

Tool Selection Flute Length

New in SOLIDWORKS CAM 2024 is the option to automatically assign tools to operations based on Flute Length. If there is more than one tool in the crib with the same diameter, the software will assign the tool that has a Flute Length closest to the depth of the feature. This gives users the best tool for the Machinable Feature Depth and removes pesky redundant tool changes.

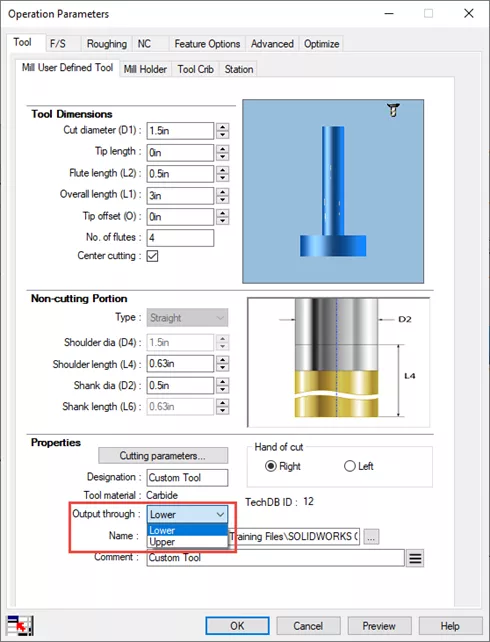

Output Options

If you use Undercut Tools like Bore, Dovetail, Keyway, or even User Defined Tools, this next enhancement will be of great interest. We now have the option to output using either the bottom or the top of the tool based on the Flute Length, making it even easier to program tools the way you want.

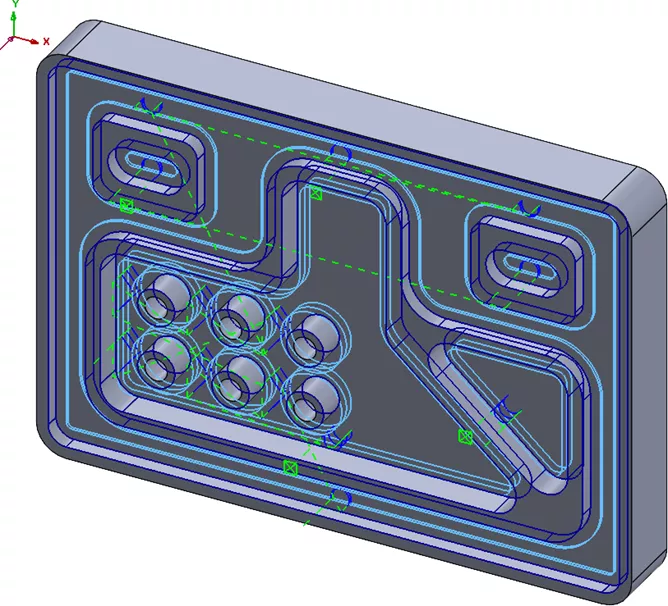

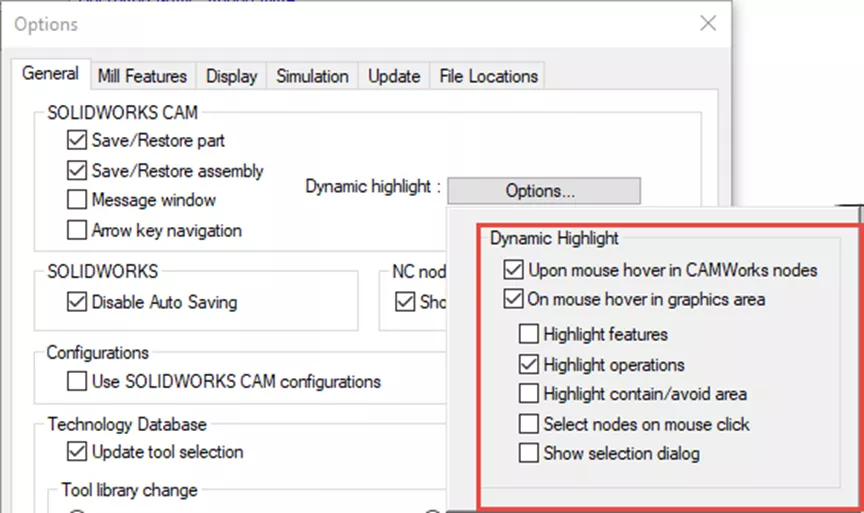

Dynamic Highlight

The last hidden gem in our tour of SOLIDWORKS CAM 2024 allows us to use geometry in the Graphics window to see what CAM items reference that geometry. To turn on the Dynamic Highlight, go to SOLIDWORKS CAM Options > General tab. Here, a variety of options are available that can be shown when mousing over geometry to display Features or Operations associated with faces or even sketches in the model, quickly giving access to machining information and making updates even easier.

As you can see, the streamlining added to SOLIDWORKS 2024 will make it much easier to manufacture products using SOLIDWORKS CAM.

On-Demand Launch Event

WATCH THE ON-DEMAND LAUNCH EVENT

Want more SOLIDWORKS 2024? Register now to join our virtual launch event on-demand to see everything new in the latest release. Our experts walk you through each enhancement across the entire SOLIDWORKS portfolio including Simulation, CAM, PDM, Electrial, 3DEXPERIENCE, and more.

Related Articles

What's New SOLIDWORKS 2024 Structure Systems

New in SOLIDWORKS Visualize 2024: Importing, Appearances, Interactive Images, & More

SOLIDWORKS 2024 STEP File Import Filter

What's New SOLIDWORKS 2024 Assemblies

About Mike Dady

Mike Dady is a Senior Application Engineer at GoEngineer. Mike spends his days working with customers to resolve their manufacturing issues and helps them to improve on existing product designs. If he’s not solving customer challenges, he’s probably at home customizing his snowmobile or working on a home improvement project.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.