TrueDent By Stratasys: New 3D Printed Denture Solution

The world of dental prosthetics is on the cusp of a significant transformation, all thanks to Stratasys , a global leader in polymer 3D printing solutions. Stratasys recently unveiled an innovative product set to redefine the way dental laboratories approach the fabrication of dentures: TrueDent™ . This groundbreaking 3D printed denture technology is primed to address the increasing challenges faced by dental laboratories in catering to the growing prosthetic needs of edentulous patients.

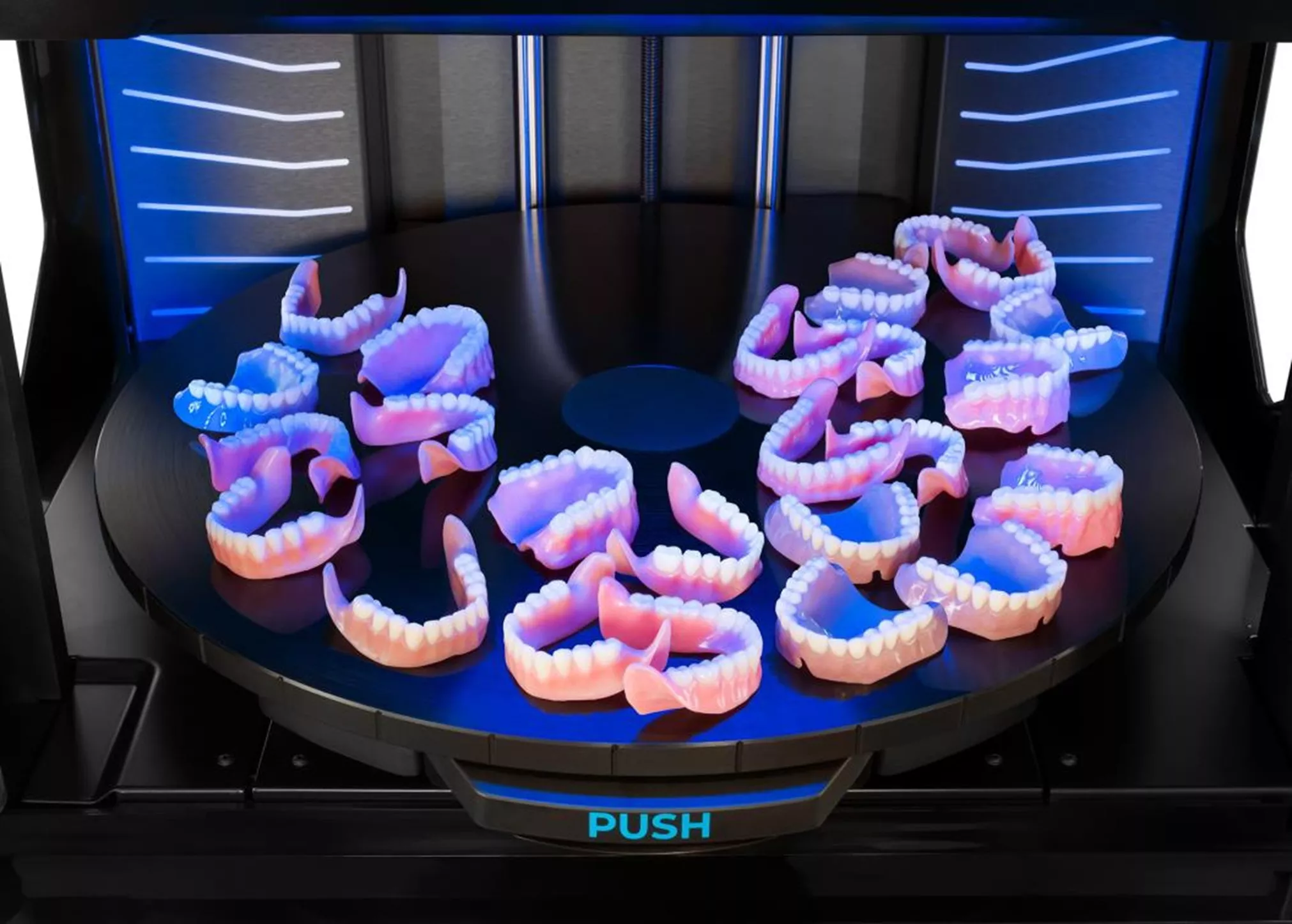

The Stratasys J5 DentaJet® 3D printer, when combined with TrueDent™, an FDA-cleared (Class II) resin formulated exclusively for dentures, paves the way for the production of single-print, polychromatic permanent dentures. This is a significant departure from conventional digital denture fabrication methods, where the denture base and teeth are printed separately using open vat photopolymerization and then bonded together.

Stratasys' innovative PolyJet technology , employed by the J5 DentaJet®, allows the combination of multiple colors of a photopolymer material. The printer then precisely deposits the material in microscopic droplets onto a build tray. Following this, a UV light cures the material, resulting in solid layers that are built up one at a time to form a three-dimensional object. With the inclusion of TrueDent™ in this process, the result is a polychromatic, single-print permanent denture offering a variety of tooth and base shades.

Advantages of TrueDent by Stratasys Resin

The novel TrueDent™ solution offers a host of benefits that significantly improve upon traditional denture fabrication methods, including:

Superior Fit: The TrueDent™ system leverages proprietary software that automatically designs the support structure for the dentures. This, coupled with the inherent accuracy of the J5 DentaJet® printer, ensures the production of dentures that fit patients exceptionally well. The comfort provided to patients and the confidence instilled in doctors make this a highly-attractive feature.

Customizable Appearance: The TrueDent™ system includes presets for a wide range of gingiva and tooth shades, facilitating high fidelity and aesthetic customization. This enables the creation of dentures that are not only functional but also visually pleasing.

Enhanced Durability: Traditional dentures often suffer from fractures at the tooth/acrylic interface, leading to failure. TrueDent™, being a monolithic denture, eliminates this point of weakness. The absence of individual teeth or a tooth/acrylic junction significantly reduces the risk of fractures, making for a more robust and long-lasting denture.

Value: TrueDent™ allows for greater printer productivity and reduced manual labor, leading to cost savings. The elimination of manual assembly and bonding of teeth to bases reduces the labor required, making TrueDent™ a more cost-effective denture solution.

Reproducibility: The digital designs of TrueDent™ dentures can be saved and reproduced later, providing an efficient and convenient solution for backup or replacement dentures.

Notably, the TrueDent™ solution also has the potential to significantly reduce chair time for office visits, measurements, fittings, and adjustments. This greatly enhances the overall patient experience, making it a highly attractive option for dental practices.

Further strengthening the potential of TrueDent™ is the recent partnership between Stratasys and the nearly century-old German Dental technology company VITA Zahnfabrik H. Rauter GmbH & Co. KG (VITA). This collaboration seeks to incorporate VITA's certified tooth shades and prosthetic expertise into the 3D printed denture solutions offered by Stratasys.

For more information about the new TrueDent™ material, the Stratasys J5 DentaJet, and the workflow for monolithic dentures, please see GoEngineer’s recently recorded webinar, TrueDent Monolithic Denture Solution: Revolutionizing Denture Production with the J5 DentaJet Printer ” below.

Video: TrueDent Monolithic Denture Solution

3D Printing Supplies

Need 3D printing supplies? Visit the GoEngineer online store .

More 3D Printing News

Dental 3D Printing Technology: PolyJet and P3

Concept to Production 3D Printing: How it Works

3D Printing In-house and Outsourcing: Why a Hybrid Approach Works

The Future of Digital Dentistry: Stratasys Solutions

About Richard Cromwell

Richard Cromwell is an Additive Manufacturing Applications Engineer based out of Auburn Hills, MI, having recently joined the team in February 2020. He is a Certified Stratasys Applications Engineer and holds a degree in Technological Science with a specialization in CAD from Oakland Community College in Auburn Hills. Before delving fully into his passion for additive manufacturing and 3D CAD modeling, Richard honed his mechanical design, CAM, and custom fabrication skills while working for over a decade as a renowned craftsman creating custom retrofit piano actions for many of the world’s most prized musical instruments.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.