Using Geomagic for SOLIDWORKS Deviation Analysis

Precision and accuracy are two important factors when 3D modeling in CAD. Engineers and designers must ensure that their digital models align perfectly with physical objects or meet stringent quality standards. That's where Geomagic for SOLIDWORKS comes into play, providing a powerful suite of tools to streamline comparing digital models with real-world objects. The Deviation Analysis feature is a game-changer for professionals seeking perfection in their designs. In this article, we explore how to use the Deviation Analysis tool in Geomagic for SOLIDWORKS and the numerous benefits it offers.

What Is Deviation Analysis?

Deviation Analysis is a sophisticated tool within the Geomagic for SOLIDWORKS, primarily used for comparing and analyzing the differences between a 3D CAD model and a physical object or scanned data, ensuring that the CAD model matches the physical object with high precision.

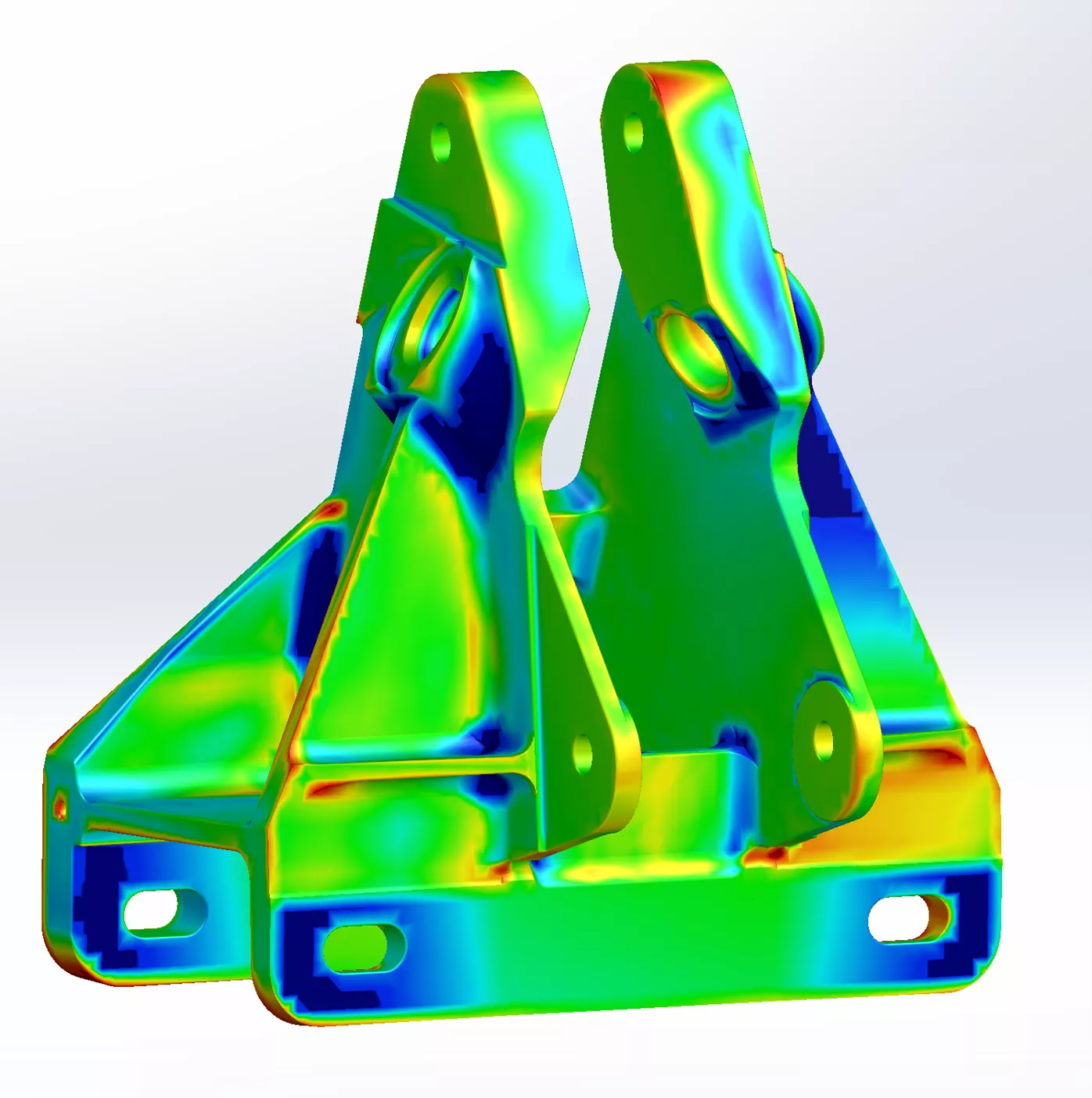

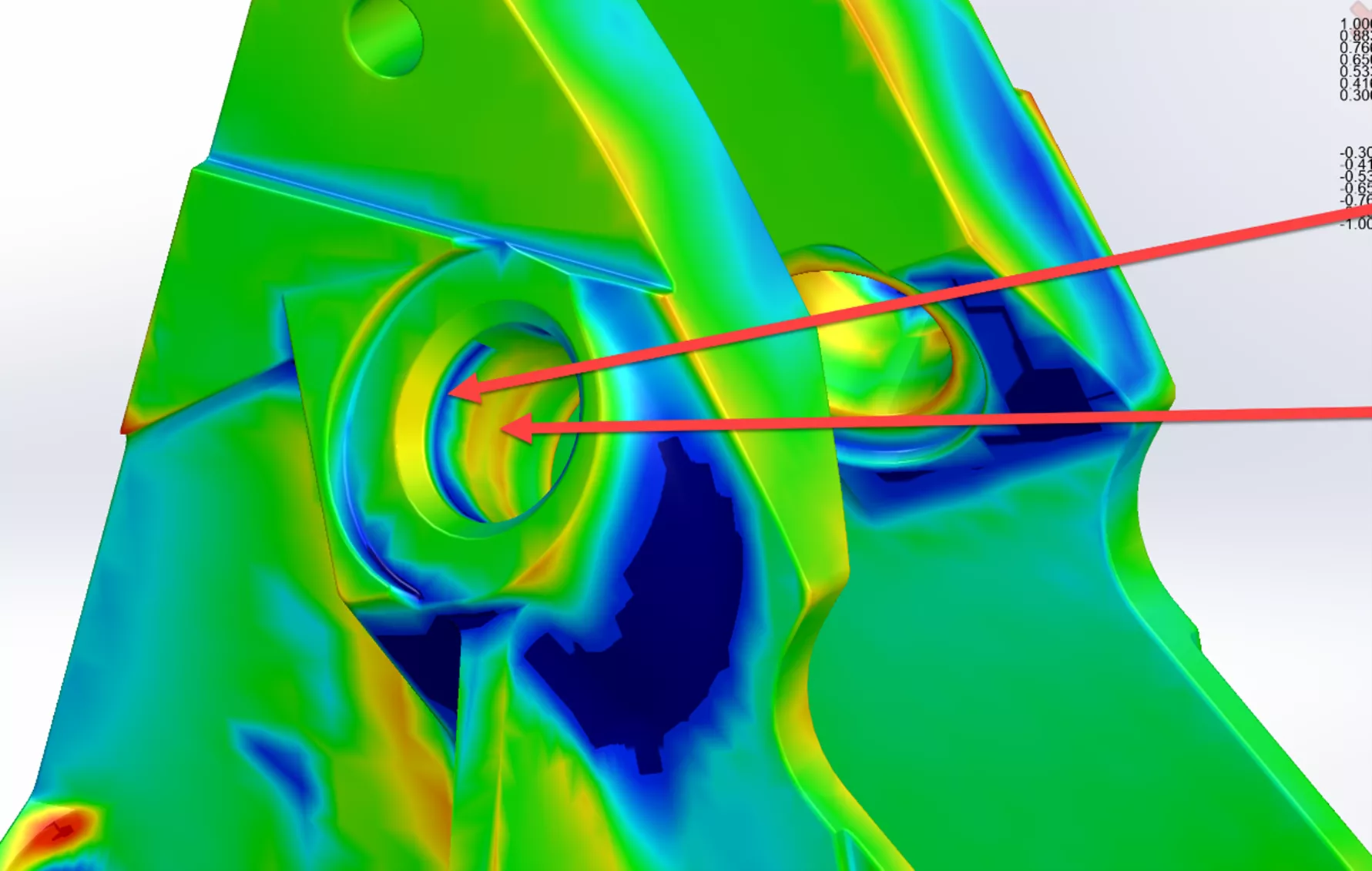

Deviation Analysis can catch minor discrepancies that might go unnoticed with manual inspection. This tool allows users to pinpoint areas of discrepancy and visualize the results, which can be invaluable for design verification and reverse engineering. The visual, color-coded maps make it easy to communicate deviations to team members and stakeholders, enabling data-driven decision-making. When reverse engineering existing objects, engineers and designers can use Deviation Analysis to refine and optimize designs iteratively, reducing the number of prototypes needed and speeding up the development process.

Tutorial - How to Use Deviation Analysis

-

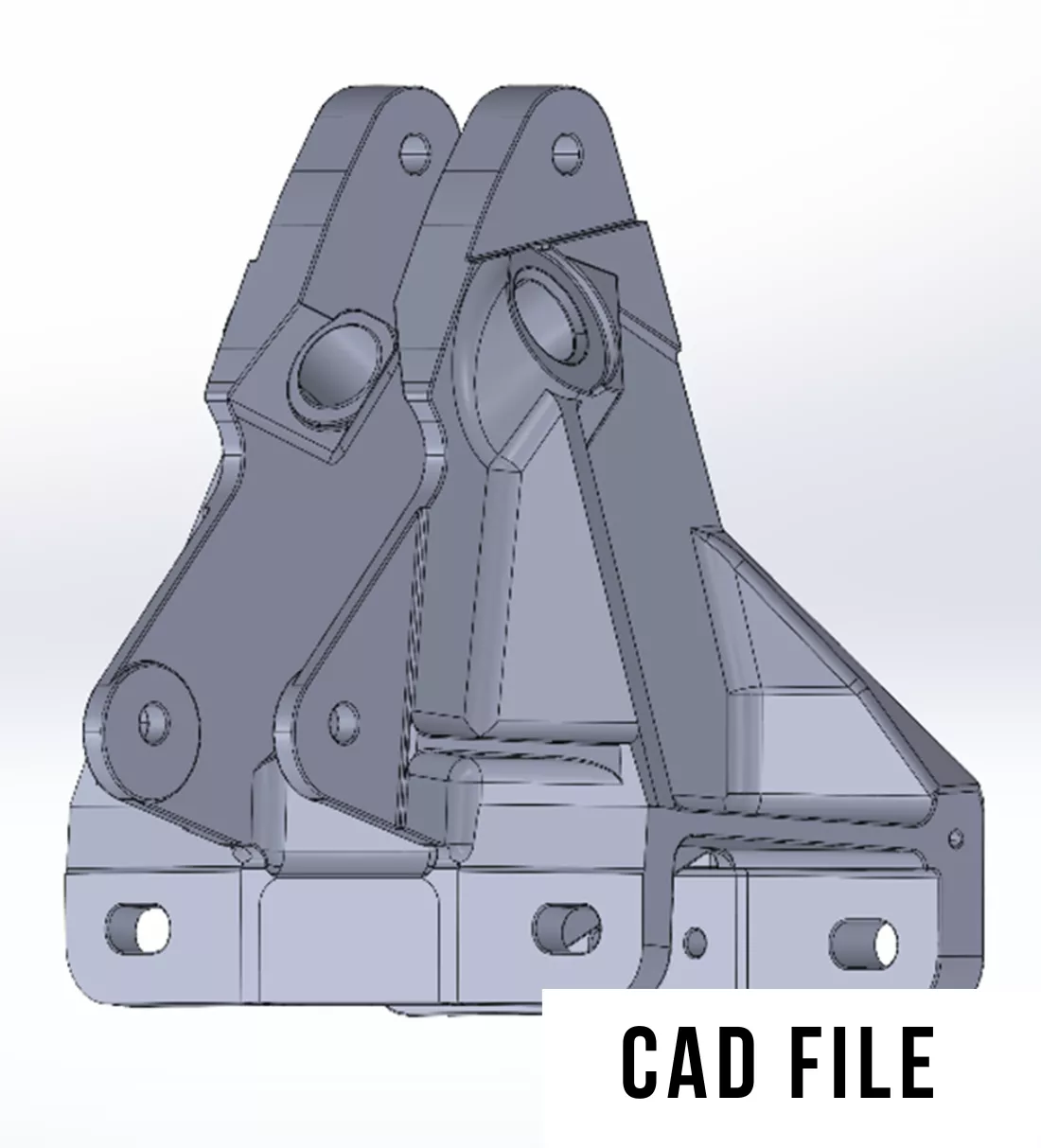

Get data into the software.

Begin by importing a 3D CAD model into Geomagic for SOLIDWORKS. Next, import the scanned data or scan the physical object to compare to the CAD model.

-

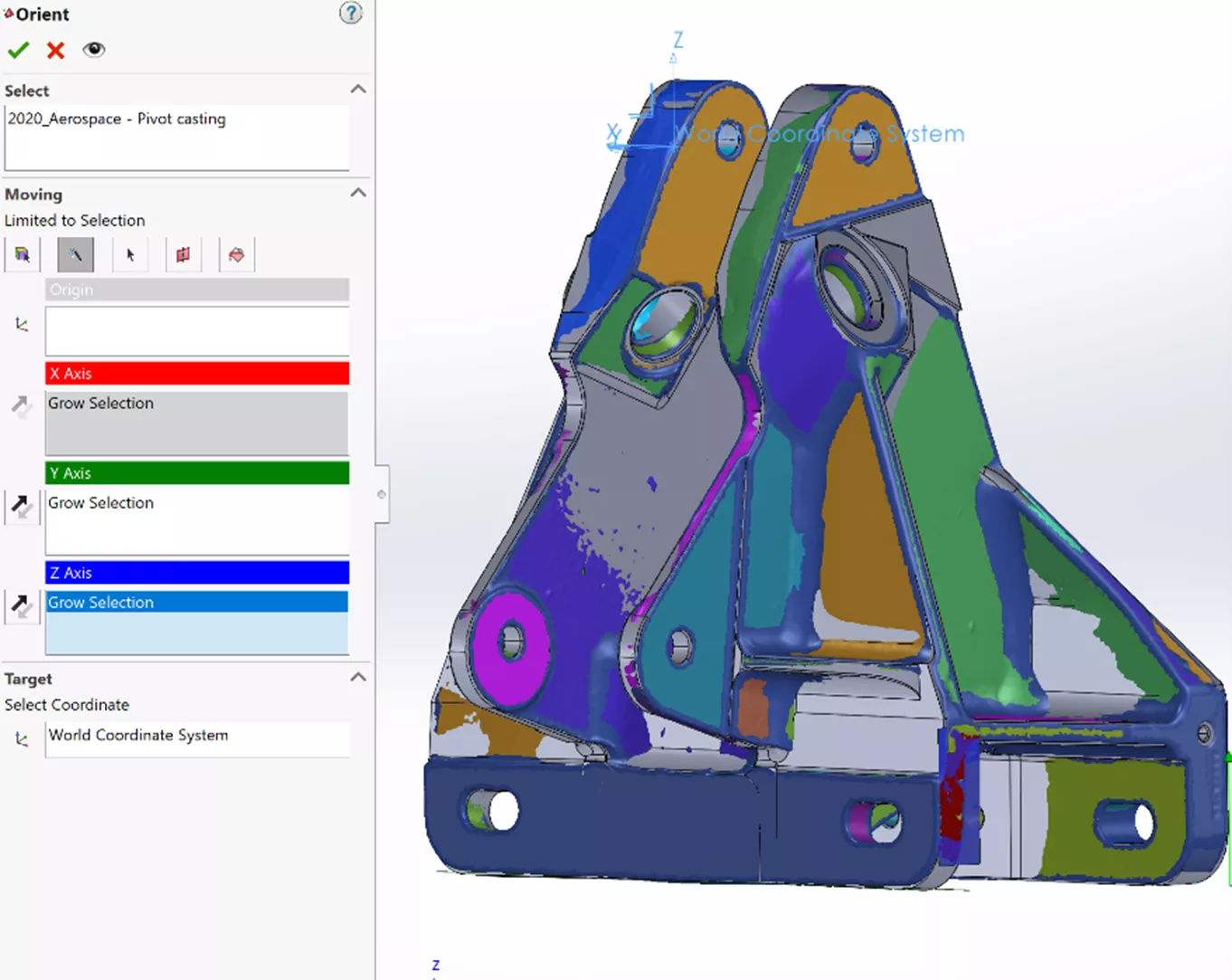

Align the models.

Use the software's alignment tools to superimpose the CAD model and the scanned data. This step ensures that they are in the same coordinate system.

-

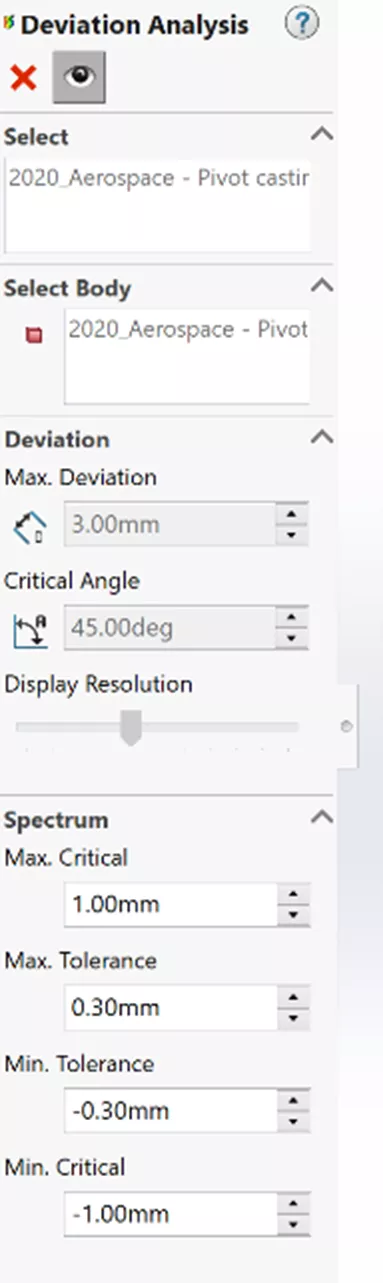

Configure Deviation Analysis.

Access the Deviation Analysis tool from the Geomagic for SOLIDWORKS menu. Set the analysis parameters (e.g., tolerance values and color mapping options) to customize the analysis according to requirements.

-

Perform the analysis.

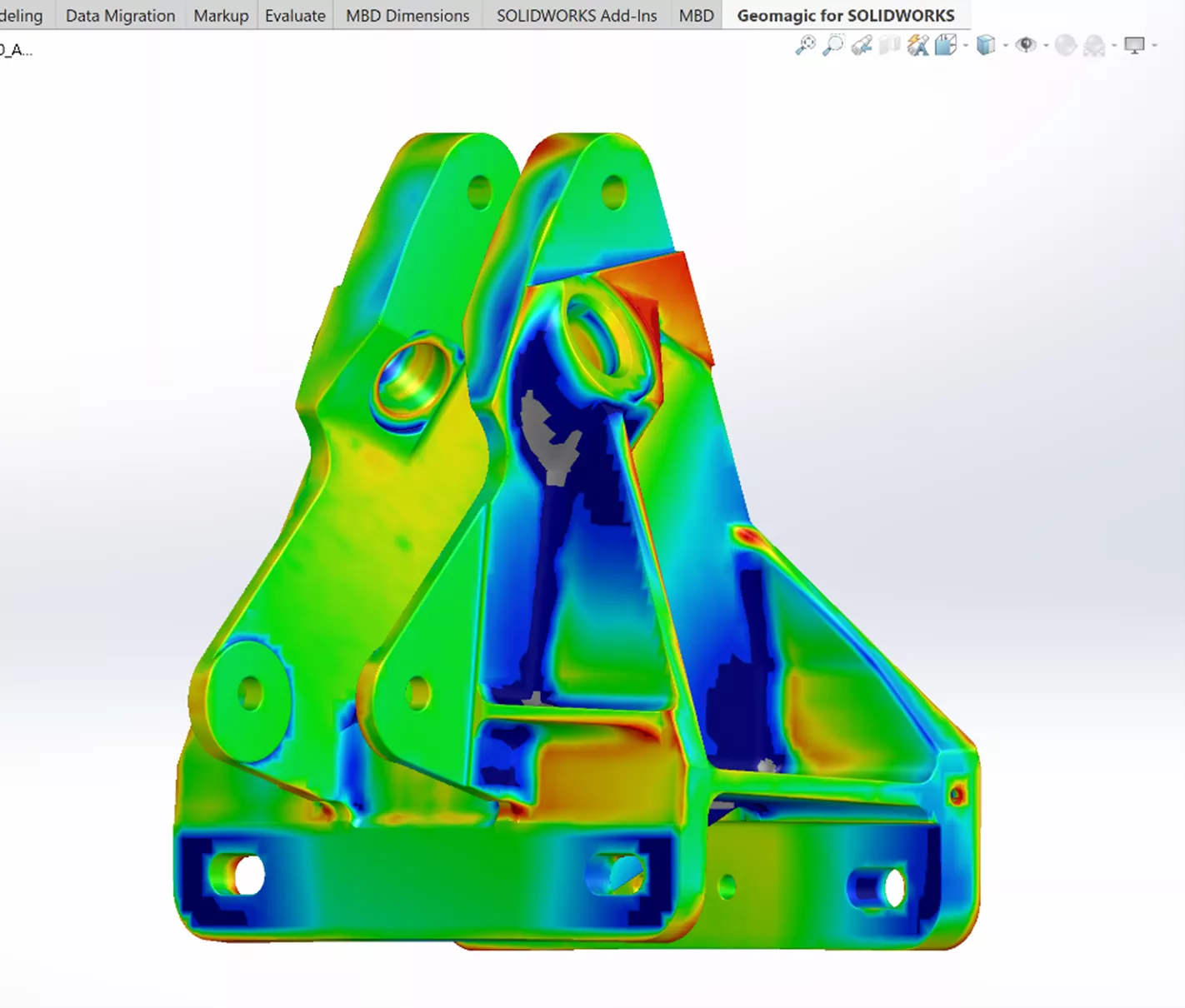

Let the software compute the deviation between the two models. The software will generate a color-coded map that visually represents the deviations making it easy to identify variances between the CAD model and the scanned data.

-

Review and interpret results.

Carefully examine the color map, which highlights areas with deviations. Utilize measurement tools to quantify the discrepancies, allowing for precise analysis of the variations.

The Deviation Analysis tool in Geomagic for SOLIDWORKS is a powerful asset for professionals in various fields, from aerospace and automotive engineering to product design and manufacturing. Its ability to pinpoint and quantify discrepancies between 3D CAD models and physical objects ensures precision, quality control, and efficiency in the design and production processes. By harnessing the capabilities of Deviation Analysis, you can enhance your designs, reduce errors, and ultimately deliver superior products to market.

Have questions? To learn more about Geomagic for SOLIDWORKS or any reverse engineering solutions available at GoEngineer, please feel free to contact us.

Related Articles

Choosing Reverse Engineering Software: Creaform & Geomagic Considerations

Geomagic Design X: Features & Tutorials

About Bob Renella

Bob is a Manufacturing Solutions Application Engineer Manager at GoEngineer.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.