SOLIDWORKS Manage

Product development and lifecycle management software

What is SOLIDWORKS MANAGE?

SOLIDWORKS Manage is an advanced data management software solution for product development and lifecycle management. Built on a SOLIDWORKS PDM Professional backbone, SOLIDWORKS Manage brings powerful reporting, item management, project and process management, and Bill of Materials capabilities to your product development and release processes.

WhO Needs SOLIDWORKS MANAGE?

SOLIDWORKS Manage enables users to collect and centrally control designs and manufacturing data distributed throughout Windows directories, share drives, and disparate software solutions. On a single platform, SOLIDWORKS Manage makes coordinating and collaborating on various activities within the product development process effortless.

SOLIDWORKS Manage is an advanced data management software solution providing similar functionality to a PLM system. Traditionally, SOLIDWORKS Manage is the next step up from SOLIDWORKS PDM Professional and users benefit from the advanced capabilities built on top of the SOLIDWORKS PDM backbone.

Tools

Product Data Management (PDM)

Product Data Management (PDM) software streamlines the management of 2D and 3D CAD files, enhancing collaboration and efficiency for engineering and design teams.

-

Manages native 2D and 3D CAD files.

-

Provides a database-driven environment for design data.

-

Enables collaborative work on the same dataset.

-

Reduces time loss from reference management and revision control.

-

Saves time by automating data management tasks.

-

Prevents hours spent fixing broken CAD models and tracking lost references.

Document Management

SOLIDWORKS Manage offers robust document management capabilities, providing record-level version and revision control for all file types that centralize and secure product documentation.

-

Provides record-level version and revision control.

-

Manages large quantities of file data.

-

Tracks, controls, links, and manages file lifecycles.

-

Covers any of the functional group's file management needs.

-

Centralizes control and lifecycle management of document records.

-

Collects, controls, and links product documentation in a secure environment.

-

Managed by a centrally-located relational database.

Records Management

SOLIDWORKS Manage records management enables the creation and tracking of non-file-based records, centralizing related data and enhancing connectivity within product data records.

-

Manages non-file-based records.

-

Collects and references all related data under a single database record.

-

Manages multiple file attachments and relationships.

-

Records have attributes, can have BOMs, and link to product data records.

-

Used by engineering and operations departments in BOMs.

-

Tracks data from quality and engineering departments.

-

Connects data typically buried in spreadsheets to product data records.

Bill of Material (BOM) Management

SOLIDWORKS Manage offers a comprehensive Bill of Materials (BOM) management toolset, integrating CAD and non-file-based records to enhance database-driven, record-centric BOMs.

-

Integrates CAD and non-file-based records.

-

Transitions engineering BOMs from Excel to a database-driven system.

-

Supports both ‘top-down’ and ‘bottom-up’ BOM management workflows.

-

Facilitates CAD-driven BOM management.

- Features include BOM comparison, export, and reporting.

- Includes variant configuration that enhances connectivity between Engineering and Manufacturing BOMs.

Process Management

Process Management in SOLIDWORKS Manage offers extensive workflow, approval, and decision-making capabilities, streamlining various business processes and product development tasks.

-

Manages workflows, approvals, and procedural decisions.

-

Configurable for various business processes (e.g., engineering change management, problem reporting).

-

Allows easy creation of tailored workflow routes with a Visio-style interface (no programming required).

-

Applies process controls to product data records, BOMs, and documents.

Task Assignment

SOLIDWORKS Manage allows for comprehensive task assignment and tracking, integrating tasks with various product data records and providing dashboards for enhanced accountability and project management.

-

Assigns and tracks task completion across the platform.

-

Tasks have creators, owners, and assignees; can be ad-hoc or linked to product deliverables.

-

Linked to various product data records (CAD data, files, BOMs, workflow states, and project stages).

-

Dedicated dashboards with calendars, timelines, and overview capabilities.

-

Facilitates accountability and time management for the product development team.

-

Supports project management with calculated time roll-ups for phase and milestone goals.

-

Tasks tied to workflow stage completion as gate-management conditions.

-

Users report completion and status updates.

Project Management

SOLIDWORKS Manage offers integrated project management with powerful project and time management tools, enhancing project deliverables and reducing time-to-market.

-

Provides integrated task management, timesheets, Gantt charts, phases, milestones, and critical path analysis.

-

Tied to projects and product deliverables.

-

Eliminates the need for disconnected project management tools from documents or records.

-

Keeps engineering projects and new product development ahead of schedule.

-

Shortens the time-to-market curve.

Dashboards and Reports

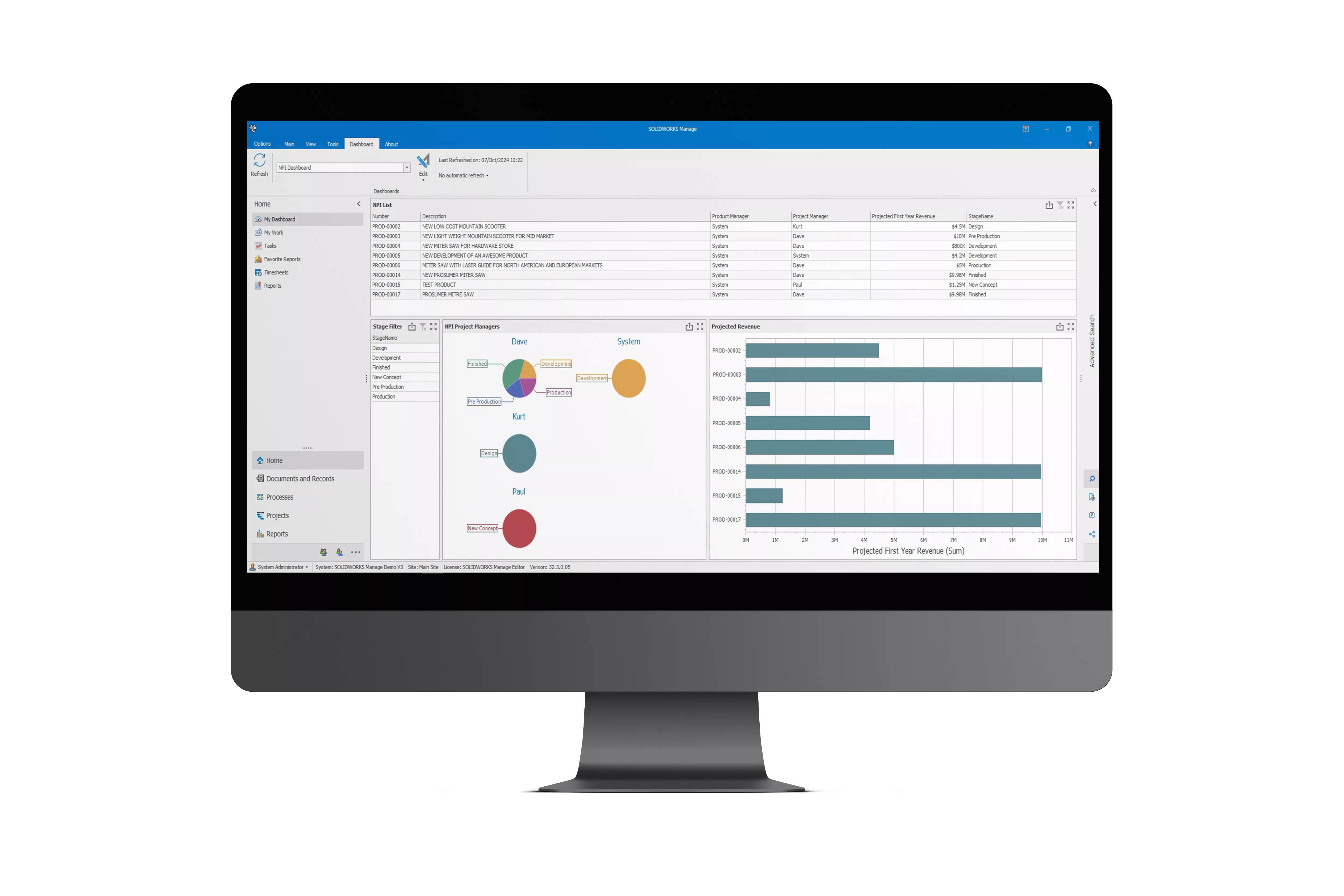

SOLIDWORKS Manage includes a comprehensive suite of built-in tools, offering customizable dashboards and automated reporting without the need for programming or third-party integrations.

- Standard and customizable dashboards for charts, graphs, tables, dials, widgets, and gauges using DevExpress.

-

No programming or third-party integrations are required.

-

Live data from SOLIDWORKS Manage and PDM, with external system integration.

-

Functions as a full BI platform.

-

Automated, repeatable reporting tied directly to source data.

-

Reports can be published on-demand or via workflow process stages.

The Top Five Reasons for Manufacturers to Improve Data Management

Today’s manufacturers face a host of challenges related to effectively managing product design and manufacturing data - not just within product development and manufacturing departments but across the greater manufacturing enterprise. How well organizations manage this data - and leverage it to support related functions - has a direct impact on a manufacturer’s ability to grow, as well as maintain and extend its competitive edge.

Read this white paper to not only learn the top five reasons why manufacturing organizations should improve their data management, but how SOLIDWORKS data management solutions will help them achieve their business goals by:

- Boosting productivity by automating manual, repetitive tasks and minimizing delays

- Improving product quality by eliminating revision errors and executing ECOs more efficiently

- Facilitating collaboration by connecting teams and linking product development with production

- Increasing organizational agility by shortening lead times and incorporating concurrent product development and manufacturing planning

- Inspiring innovation by more efficiently eliciting feedback from across the enterprise

Tools

Product Data Management (PDM)

Product Data Management (PDM) is an engineering document control software that manages native 2D and 3D CAD files. PDM software provides a database-driven environment to manage design data that enables engineering and design teams to work collaboratively on the same dataset and maximize their efficiency. PDM alleviates the overhead of non-value-add time loss associated with reference management and revision control of CAD data when saving CAD files either within Windows directories or non-PDM document management software that is not capable of understanding CAD file relationships. PDM immediately returns valuable time normally lost by managing data manually allowing your engineering and design teams to be more efficient and maintain focus on the job at hand. Without PDM, teams can spend hours of their day ‘fixing’ broken CAD models and tracking down lost references before they can begin working.

Document Management

The document management capabilities of SOLIDWORKS Manage provide a quality management system (QMS) level of capability to the job of version and revision control for all file types. A typical product development process generates large quantities of file data that must be tracked, controlled, linked, and 'lifecycled'. This covers an entire organization’s file management needs well beyond just managing MCAD design data from SOLIDWORKS. Document records can now be centrally controlled and lifecycle managed within a single system that has a place for product documentation to be collected, controlled, and linked together within a secured environment and managed centrally by a relational database.

Item Master Records Management

When it comes to records management, SOLIDWORKS understands that not everything is a CAD model or a spreadsheet. Item Master records management allows the creation and tracking of non-file-based records called Items. Item management allows for the representation of all of the related data for a record to be collected and referenced under a single database item. An item can manage multiple file attachments and relationships without being a file itself; items have attributes, can have BOMs and be used in BOMs, and have relationships and links to the rest of the product data records. Engineering and operations departments use item masters in BOMS and link them as needed throughout the product data record. Item Master management capability allows for the tracking of data from quality and engineering departments that are typically buried in spreadsheets and not connected effectively to the product data record.

Bill of Material (BOM) Management

Bill of Materials management is a robust toolset that can integrate CAD as well as non-file based item master records to allow your engineering BOMs to break free of Excel and unlock the full potential of a database-driven item-centric BOM record. Workflow options exist within SOLIDWORKS Manage for both ‘top-down’ and ‘bottom-up’ BOM management that works equally well for companies that prefer to build a BOM structure first and then work backward into the supporting design and specification data later and for companies that prefer CAD-driven BOM management where deep integration is necessary between the MCAD BOM from SOLIDWORKS and the engineering BOM record managed by operations. BOM comparison, kit BOMs, multi-site, and BOM variant configuration management capabilities are but a few of the array of features that come standard with SOLIDWORKS Manage BOM features.

Process Management

Process Management covers a wide range of workflow, approval, and procedural decision-making capabilities that help manage every facet of the product development process. Process records may be configured to handle any business process application including engineering and document change management, problem reporting, ticket tracking, corrective and preventative action reports, non-conforming material reporting, training records management, and new product development. Building tailored workflow routes becomes as easy as drawing a Visio-style flow diagram (no programming required). Create process controls that can be used and applied to product data records themselves… the item masters, BOMs, and documents managed throughout the system.

Task Assignment

Assign and track task completion across the platform. Task records have creators, owners, and assignees and can either ‘float’ ad-hoc or are directly linked to product deliverables. Because they are sewn throughout the environment, they may be linked to all types of product data records (CAD data, files, Item masters, BOMs, process workflow stages, and project phases). Tasks have dedicated dashboards with calendars, timelines, and review capability. Provide your entire product development team with an easy and compelling method to create accountability and allow for anything from simple ad-hoc time management or used in concert with project management for calculated time roll-ups associated with phase and milestone completion goals. Tasks can be tied to workflow stage completion as gate-management conditions required to proceed to the next stage of the process. Tasks eliminate the need for project managers to poll users to determine where they are within a job. Instead, users can directly report completion and status updates within task-based SCRUM project sprints.

Product Portfolio Management

Integrated product portfolio management (PPM) for every facet of the product development process. SOLIDWORKS Manage is equipped wit powerful project and time management tools that are tied to projects and product deliverables. Stop using disconnected project management tools that ‘pretend’ to deliver results but are not tied to the deliverables that they purportedly ‘manage’. With integrated task management, timesheets, Gantt-charts, phases, milestones, critical path analysis, and data analytics tools SOLIDWORKS Manage keeps engineering projects and new product development efforts ahead of schedule and shortens the ‘time-to-market’ curve.

Data Analytics

SOLIDWORKS Manage comes standard with a whole suite of data analytics tools built-in and easily configured. There are no programming or system integrations required nor dependence on third-party business intelligence tools. The suite of analytical capabilities breaks down into two main functional areas to cover both dashboarding and reporting requirements. Dashboarding includes both standard ‘built-in’ dashboards as well as fully configurable/customizable dashboards for charts, graphs, tables, dials, widgets, and gauges. Dashboards present users with live data from SOLIDWORKS Manage and PDM and can also confederate data from external systems and be used as a full BI platform. With SOLIDWORKS Manage, you can stop struggling with Excel and racing to keep your data up to date and accurate. Reporting will tie you directly to your source data and make preparing reports an easy, repeatable, and automated process. Reports can be published on-demand or executed automatically by a workflow process stage.

Frequently Asked Questions

Both PDM and Manage use the same licensing tiers: Editor, Contributors, and Viewers. Editors are for CAD editors, Contributors are for non-CAD editors, and Viewers are for read-only records access. All license types are concurrent-use ‘floating’ networked global licenses.

To begin with, Manage comes out-of-the-box integrated into SOLIDWORKS PDM for full system, bi-directional access. The level of sophistication of this integration between Manage and PDM is orders of magnitude deeper than could be done with third-party PDM sy. Manage has total situational awareness and control over PDM. Integrations between Manage and third-party systems such as ERPs may be done with a variety of techniques. Manage comes with powerful built-in data transformation and extraction tools for point-to-point data pushes as well as an open SQL database for middleware-based extractions and transformation.

SOLIDWORKS PDM is a file-based system, meaning every action requires an accompanying file. SOLIDWORKS Manage is an added layer onto an existing SOLIDWORKS PDM environment that adds record management processes like reporting, process and project management, and item management.

The Top Five Reasons for Manufacturers to Improve Data Management

Today’s manufacturers face a host of challenges related to effectively managing product design and manufacturing data - not just within product development and manufacturing departments but across the greater manufacturing enterprise. How well organizations manage this data - and leverage it to support related functions - has a direct impact on a manufacturer’s ability to grow, as well as maintain and extend its competitive edge.

Read this white paper to not only learn the top five reasons why manufacturing organizations should improve their data management, but how SOLIDWORKS data management solutions will help them achieve their business goals by:

- Boosting productivity by automating manual, repetitive tasks and minimizing delays

- Improving product quality by eliminating revision errors and executing ECOs more efficiently

- Facilitating collaboration by connecting teams and linking product development with production

- Increasing organizational agility by shortening lead times and incorporating concurrent product development and manufacturing planning

- Inspiring innovation by more efficiently eliciting feedback from across the enterprise

Compare Packages

Standard

Professional

Manage

- Manage and control your product development data with a secure file vault. SOLIDWORKS PDM manages all SOLIDWORKS file references and automatically updates them whenever you move or rename files, eliminating broken references.

- Quickly locate and reuse existing designs to save time and control costs. Instead of spending time locating prior designs on shard drives or recreating designs when you can’t find them, use SOLIDWORKS PDM tools to locate them quickly.

- Track design changes automatically and maintain a complete revision history with a standardized process that’s customized for your company’s needs.

- With SOLIDWORKS PDM your company’s sensitive and proprietary data is secure, up-to-date, and accessible with configurable security controls. User permissions can be assigned based on individuals, groups, or company role. Every change is tracked and unauthorized changes are eliminated.

- Ensure you are always working with the “right version” of a design with SOLIDWORKS PDM’s revision and version control capabilities. You can customize file naming and revision control schemes, maintain document history, and easily manage document versions to avoid the costly manufacturing errors associated with working with the wrong revision.

- Maintain a complete history of your product design, engineering, and development activities for reporting and auditing purposes.

- View eDrawings, SOLIDWORKS, and AutoCAD documents in eDrawings inside SOLIDWORKS PDM. With SOLIDWORKS PDM Professional you can view multiple other file types including MicrosoftOffice documents.

- Save time and reduce development costs through design reuse by quickly finding needed data across a range of file types using the powerful searching tools PDM offers. You can quickly perform file content searches on multiple data types (such as CAD files, Microsoft Word documents, Excel spreadsheets, Outlook emails, and images) and locate documents using a range of search criteria (including name, date, metadata, and workflow status).

- Reduce the time to complete design approvals and Engineering Change Orders (ECO). The product development process is graphically represented through an easy-to-use flowchart interface. Engineering change documentation and change approvals become completely electronic with SOLIDWORKS PDM Professional.

- Maintain, manipulate, and leverage Bill of Materials (BOM) information to support downstream applications and systems. Create individual BOM objects from existing CAD file structures that automatically update in parallel with design changes, eliminating manual updates and required when using spreadsheets. Connect your CAD data with your ERP or MRP systems, enabling you to easily update BOM information in other businesses applications. BOM information can be customized using templates to meet the needs of different users and groups.

- Facilitate compliance with government regulatory requirements and industry standards. SOLIDWORKS PDM Professional can bolster compliance for several types of regulatory requirements, including: FDA, RoHS, ISO 9001 and 14000, ANSI, and others..

- Create and maintain a single data location and vault that can be accessed by users worldwide to store and retrieve files. In addition to preserving a secure backup of product design data, secure file vaulting eliminates multiple sources of information, duplicate files, and unsynchronized revisions. SOLIDWORKS PDM Professional can be customized to meet the specific needs of your organization.

- Collaborate throughout your organization while keeping people connected, current, and working on the same set of data. Create and maintain a single data location and vault that can be accessed by users worldwide to store and retrieve files. Configure the SOLIDWORKS PDM Professional system to automatically notify users when documents have progressed through various states or stages in the electronic work flow you establish. Automatically create many types of neutral file formats from SOLIDWORKS and other file types.

- Save and share search criteria as “favorites”, providing you with instant access to common searches.

- View multiple documents in the Preview window.

-

SOLIDWORKS PDM Professional provides one convenient, vaulted

location where colleagues can store and retrieve company data.

Efficient file storage and retrieval enables millions of files to be

managed effortlessly.

- Save time and effort communicating by configuring SOLIDWORKS PDM Professional to automatically create neutral file formats.

- Use serial numbers to assign automatic names to files and folders, to assign unique IDs to items, or to add unique running values to card controls. You can set up any number of serial numbers in each vault. Item Number serial numbers are defined by default to generate unique item IDs.

- Map variables to both predefined properties (such as Title and Author) and custom named properties in SOLIDWORKS files. If a SOLIDWORKS file contains configurations, the configuration names appear as tabs in the data-card. Configuration-specific values are shown in the corresponding tab.

- SOLIDWORKS PDM Professional can import variable values from an XML file into a vault database. In the vault, existing files or items that match import criteria acquire the values at specified points in the file work flow. Create an export rule to export SOLIDWORKS PDM BOM variables that can be read into ERP systems.

- SOLIDWORKS PDM Professional provides the tools and capabilities that your enterprise needs to keep people connected, up-todate, and working together, regardless of location. This global connectivity supports the distributed collaboration essential for reducing engineering development and accelerating time-tomarket.

- Enable staff and partners to contribute through web-enabled portals from various connected devices including smart phones and tablets.

- Automatically facilitate multiple required approvers with parallel transitions.

- SOLIDWORKS PDM can automatically send email notifications to alert users of changes to projects or requests for them to take actions.

- Provide critical information to help teams focus on important tasks, and provide an overview of resource capacity for better planning and utilization. Manage project stages, time lines, and milestones along with resource utilization and capacity. Utilize user tasks and time sheets to automatically track progress.

- Streamline business processes, automate document creation and bring together all involved stakeholders for new products, from sales and marketing to production and support. Configure states and decision points for all types of business processes such as Engineering Change Requests (ECR), Orders (ECO) and Notices (ECN), transmittals and approvals.

- Create, edit and compare complete bills of materials (BOM) by associating items, files and free text. Manage product variations for different use cases and applications. Drive SOLIDWORKS drawing bill of materials and item numbers directly from system data.

- Provide users with the knowledge they need to work more effectively by utilizing tasks and calendars.

-

Create and distribute interactive graphical dashboards to display

critical information. Configure reports to company

Going Beyond SOLIDWORKS Manage

ENOVIA PLM Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

DELMIAWORKS Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

SOLIDWORKS Services:

Utilize GoEngineer’s Award Winning Support & Training for SOLIDWORKS

Award Winning Technical Support

GoEngineer's extensive SOLIDWORKS technical knowledge and world class support can help you succeed with SOLIDWORKS. Our award-winning team is ready to help you with any task you may have. Using state-of-art remote assistant technology software allows our team to solve most issues within one session. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

- 125+Certified Technical Specialists

- Email, Phone and Chat Support Available

- 98% Exceptional Customer Service Rating

PROFESSIONAL SOLIDWORKS TRAINING

GoEngineer offers online and classroom professional SOLIDWORKS training for organizations and individuals. All our instructors are SOLIDWORKS certified and teach thousands of students each year world wide. The curriculum is very diverse with numerous certified SOLIDWORKS courses to choose from. Each student will receive a Course Completion Certificate and preparation materials for SOLIDWORKS certification.

- Increase Your Earning Potential

- Led by Certified SOLIDWORKS Instructors

- Smaller Classes with Focused Attention

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services