3D Technology and Archaeology: Enabling Artifacts to Virtually & Literally Travel the World

3D Scanning, 3D Printing & Artifacts

3D scanning and 3D printing technologies are enabling artifacts to virtually leave museums and laboratories via the internet. Exact physical copies can travel the world to help researchers make connections among different artifacts to solve archeological mysteries or enable students to learn hands-on from 3D models.

For the uninitiated, 3D scanners use structured light or lasers to capture 3D surface data, including color and texture, from an object. Traditional 3D scanners, such as tripod or arm scanners, have many limitations. For example, they may need to be bolted to a table or require numerous setups. Older scanning technologies are typically large, heavy, stationary assemblies that must have a fixed position, and they usually require a longer setup and calibration time.

Creaform 3D scanners are handheld and are non-contact so the scanner itself does not touch the part. They are also lightweight, thus easily used for long periods of time on any size object, from a single mouse tooth to a dinosaur, and the smallest scanners fit in a case no bigger than carry-on luggage. This versatility enables 3D technology to support archaeology in four main ways: 3D archives, virtual museums, restoration and repair, and preservation.

3D Archives

Universities and museums can create digital libraries of their fossils and make them available to students or researchers who can view, rotate, and zoom in on a 3D artifact from a computer.

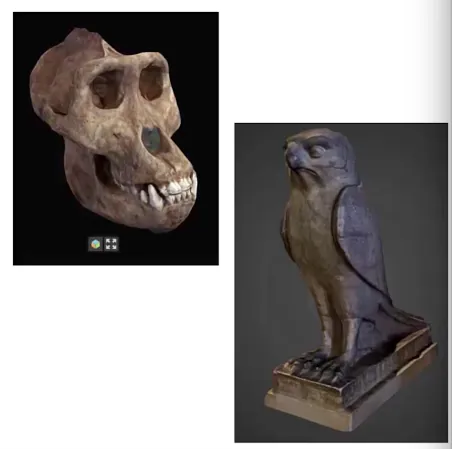

Images from africanfossils.org (left) and sketchfab.com (right). Both websites have digital libraries where students can view and study hundreds of 3D-scanned artifacts.

In addition to being available to anyone in the world, a database containing 3D images has the advantage of superior organization: A viewer can see an entire artifact within a singular file instead of having to open multiple photographic images. Also, 3D images of artifacts can be studied and archeology learned via a digital library.

Archaeological collections and museums are open 24/7/365 through any internet-connected device. Further, archeological databases enable archaeologists and researchers to collaborate at a global level, especially to compare artifacts from different regions of the world, thus piecing together the never-quite-solved puzzle of archeology.

Virtual Museums

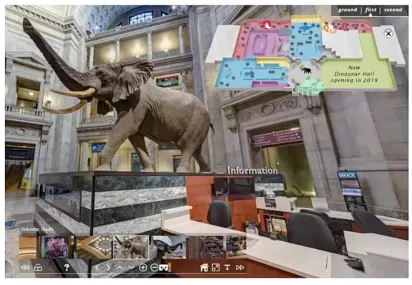

Any artifact can be scanned and be available on the web. Most of the Smithsonian Museum of Natural History in Washington, D.C., is on https://naturalhistory.si.edu, thereby expanding access to the museum to anyone with an internet connection—no plane tickets or hotel reservations required.

Image from the Smithsonian Museum of Natural History

A viewer can take a virtual tour of the entire museum and click on an artifact for a description—the computer becomes just like a tour guide. Links provide additional information and options for further reading and study on an artifact.

Restoration and Repair

3D printers play a complementary role by creating physical 3D models from the data captured by the Creaform scanner and finalized in SOLIDWORKS. Stratasys PolyJet 3D printers can even print color and texture. Priceless fragile ancient artifacts can break when being transported, handled, or cleaned, and 3D scanning and 3D printing offer a very effective solution.

After an artifact is put back together using glue or other methods, it can be 3D scanned, including holes or cracks, which can be “fixed” with SOLIDWORKS. For example, the image below is a bronze statue that had broken hands for which a museum used 3D technologies to create replacements.

Another application is the creation of missing components. For a sculpture missing a left arm, for example, a 3D scan of an intact right arm can be mirrored by CAD software such as SOLIDWORKS to create a file to print the missing arm. If replacement parts must be made from a specific material, SOLIDWORKS can be used to create a file for a mold that can be 3D printed.

3D scanning can also help create custom stands or joints for artifacts such as skeletons. After the mating surfaces are 3D scanned, a custom stand or joints can help restore such artifacts to their original position.

Preservation

Together 3D scanning, 3D CAD, and 3D printing can help preserve priceless artifacts. Duplicates of fragile artifacts can help preserve originals by eliminating the need to move or transport an original, which invites the opportunity for damage. 3D-printed copies also enable students to interact with otherwise untouchable relics for hands-on learning experiences.

Another application is creating scale models of artifacts that are too large to easily examine. 3D-scanned artifacts can be 3D printed at a much lower scale. This allows the artifact to be passed around classrooms, providing much more immediacy and detail than a picture on a screen or a photo in a textbook.

When actual artifacts must be moved, custom-designed packaging can be created from 3D scans and 3D prints to help ensure artifacts arrive undamaged when transferred between museums.

Source: https://store.finemineralia.com/Fossil-Mosasaur-Skeleton_p_201.html

Because of 3D technologies, Artifacts are virtually and literally available to anyone in the world. GoEngineer is currently working with the University of Wyoming, the Idaho Museum of Natural History, and George Mason University.

Contact us if you have questions about how GoEngineer’s 3D technologies can help your school’s archaeology program.

Learn More about 3D Scanning

Creaform Releases New HandyScan 3D Silver Series 3D Scanners

Artec Micro Desktop 3D Scanner: Full Function Freedom

New Creaform 3D Scanner Updates for 2020

The GoEngineer Trifecta: Creaform, Geomagic & Stratasys

Wonder Woman Costume Comes to Life with 3D Printing, 3D Scanning, & 3D Design

About William Huertas

William is an Applications Engineer for GoEngineer. He graduated from CSU Los Angeles with a Bachelor’s and Master’s degree in Industrial Technology. His expertise lies in 3D printing, 3D scanning, and reverse engineering applications. Using the latest technology, he enjoys helping customers improve their design and manufacturing process.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.