The Value of SOLIDWORKS PDM for High-Performing Teams

Efficient engineering is built on a foundation of collaboration, version control, and the ability to manage data seamlessly across teams and tools. SOLIDWORKS Product Data Management (PDM) stands out as a comprehensive solution that helps overcome common challenges, such as misplaced files, outdated versions, or workflow bottlenecks. As engineering teams face increasingly complex projects, adopting robust systems like SOLIDWORKS PDM becomes essential for maintaining high performance. Below, we’ll walk through key benefits, use cases, and features of SOLIDWORKS PDM.

Ease of Use Without Intimidation

Switching to new tools often comes with a learning curve, but SOLIDWORKS PDM is designed to be intuitive, familiar, and configurable to fit your team’s workflows. Its integration into Windows File Explorer enables users to begin using the tool with minimal ramp-up time. Whether you’re navigating file structures, previewing metadata, or viewing CAD-specific files, everything is approachable.

PDM is essentially an extension of Windows File Explorer with added functionality. Users can access detailed previews for files without the need for specific software, allowing teams to gather insights on components or drawings without opening bulky CAD files. This focus on ease of navigation ensures engineers spend less time searching for data and more time developing solutions.

Creating a Single Source of Truth

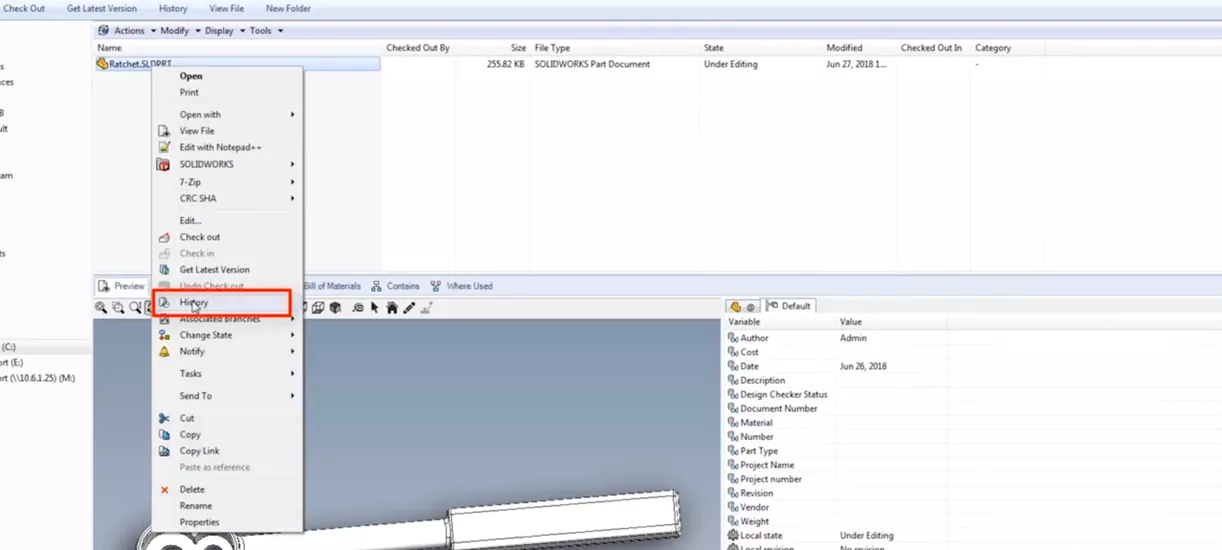

With SOLIDWORKS PDM, there’s no more guessing which file version is the most up-to-date. Version control is automatic. Every time a file is checked back into the system, PDM saves a new version, allowing teams to roll back to previous iterations if needed. This ability to maintain a single source of truth is critical not only for engineering but for downstream processes, like manufacturing and assembly.

From small tweaks to design overhauls, every modification is documented, ensuring data security while maintaining auditable records for compliance standards.

Collaboration Across Teams and Tools

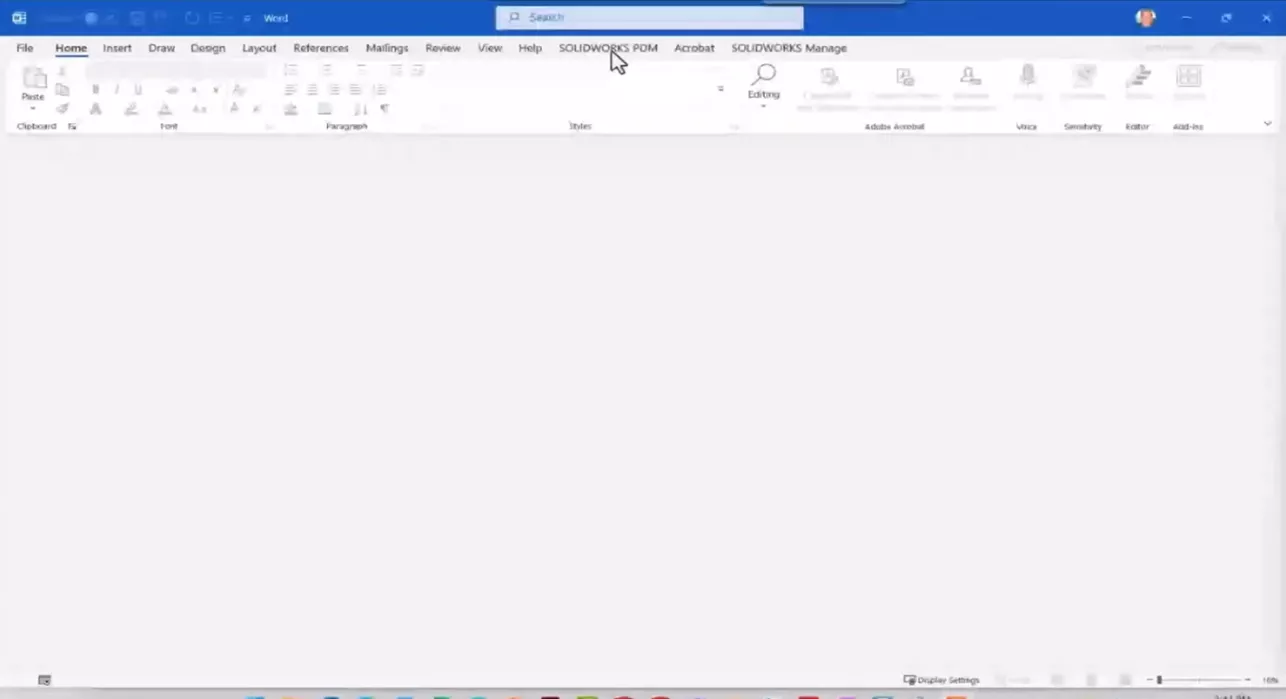

Collaboration is no longer confined to just the engineering department. SOLIDWORKS PDM bridges silos by extending its functionality to tools used by marketing, sales, and management teams. With Microsoft Office add-ins for tools like Word, Excel, and PowerPoint, users can manage and edit files directly within the environment they’re familiar with.

With SOLIDWORKS PDM, engineers can create “packets” of related documents, linking a CAD design to its proposal or project timeline in Word. On the operational side, sales teams can stay updated on a product’s status without needing to touch the engineering workflow, while marketing teams can confidently use up-to-date assets for campaigns.

Optimizing Local File Access for Performance

For those working with large assemblies, SOLIDWORKS PDM’s ability to bring files local to your computer drastically improves performance. Instead of relying on external connections, accessing files locally ensures faster operations and reduces bottlenecks.

For distributed teams, file replication allows employees in different locations to access files without unnecessary delays or duplication issues, ensuring group-wide synchronization.

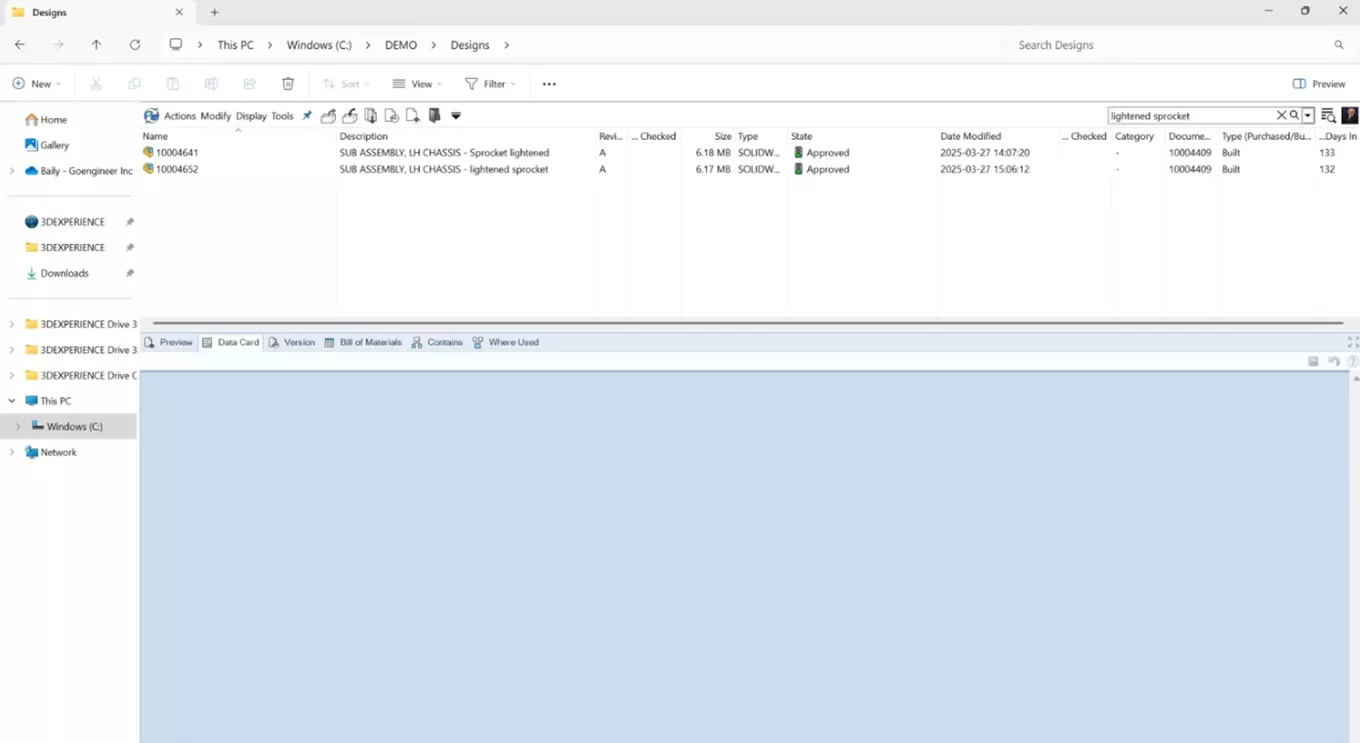

Advanced Search and Reuse

Engineering teams waste valuable time hunting for files or reworking data that already exists. SOLIDWORKS PDM addresses this by providing advanced search capabilities that allow users to locate lost or misplaced files instantly. The integrated search functionality is contextual; you can filter documents based on metadata, workflow states, or version history to locate exactly what you need without combing through folders.

The ability to capture and reuse engineering data has another added advantage: cutting down on redundant work. Data that already exists can easily be applied to new projects or delivered to clients, leading to faster turnarounds and higher-quality solutions.

PDM Workflows: Automating Approval and Notifications

One of the standout features of SOLIDWORKS PDM is its ability to automate workflows, implement approval structures, and track processes transparently. Whether it’s transitioning files among departments or triggering notifications, workflows ensure that each step in the process adheres to company standards and defined logic.

Here’s how workflows benefit teams:

- File Editing States: Documents are segmented into states, such as Editing, Waiting for Approval, and Approved, ensuring only relevant stakeholders have access to a file at any given moment.

- Approval Transitions: Workflow transitions, triggered manually or automatically, notify appropriate team members when a file moves to the approval stage while locking its editing permissions.

- Flexible Approvals: Whether your team needs serial approvals (one after another) or parallel ones (at the same time), the system supports configuration to match your needs. For example, multiple managers can evaluate a file concurrently while maintaining traceable records of who approved what.

- Automation Post-Approval: Following an approval, the system can update revision histories, notify teams, or export file types needed for manufacturing.

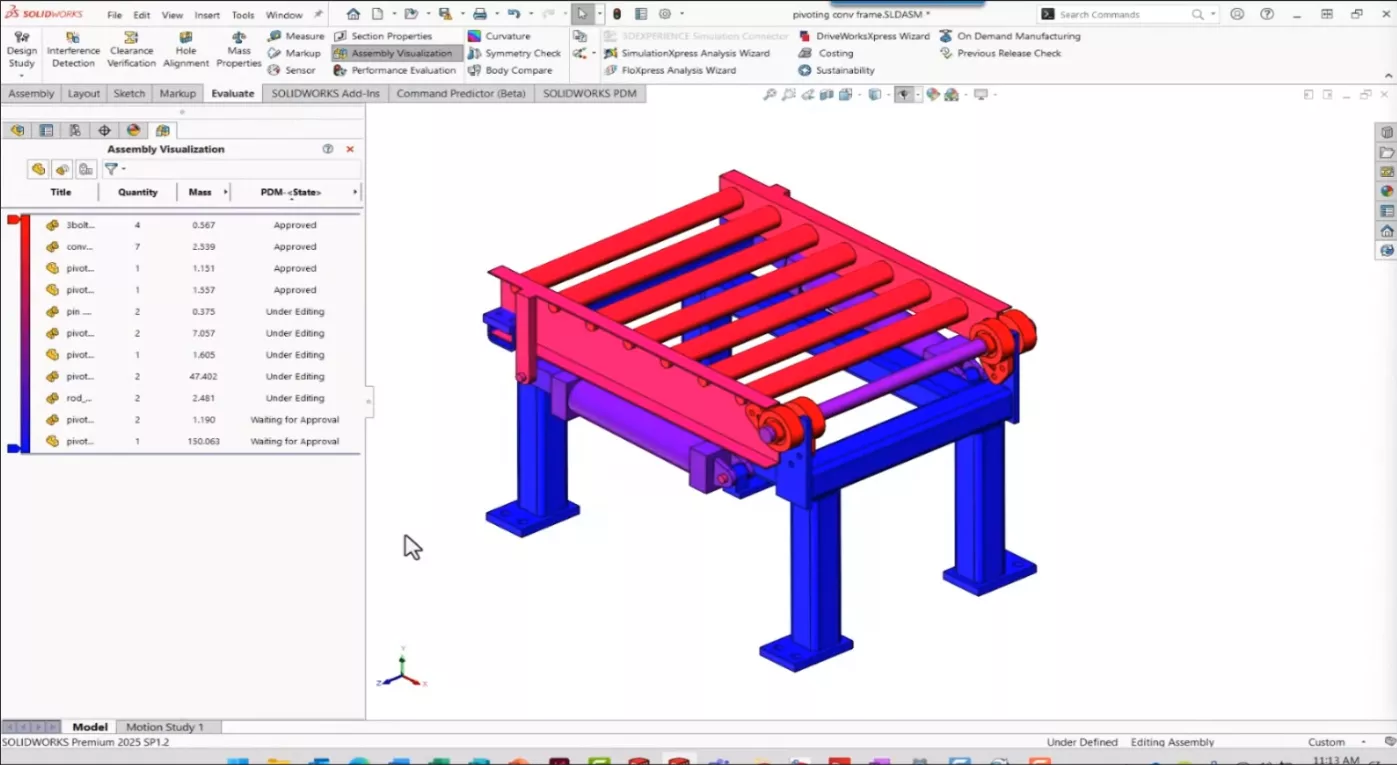

Visualizing BOMs and Data in 3D

Teams often struggle to pull key insights from raw data, especially when managing complex assemblies. SOLIDWORKS PDM integrates directly into the 3D CAD environment, allowing users to visualize Bills of Materials (BOMs) and workflow statuses within the model assembly environment.

Color-coded indicators show a clear picture of file statuses, whether parts are approved, under editing, or queued for approval. Engineers can sort BOMs by their workflow state or quickly access files’ metadata using right-click commands. This in-tool visualization eliminates the need for switching between software, simplifying data access and decision-making.

Notifications That Keep Teams Aligned

SOLIDWORKS PDM’s notification features help keep collaboration smooth and timely. With a dedicated PDM inbox, users can view folder-specific or workflow-triggered alerts without cluttering their regular email inbox. For external notifications, integration with Outlook ensures stakeholders outside engineering stay informed about progress.

A particularly valuable aspect of PDM notifications is their action-driven hyperlinks. These embedded links allow recipients to open documents directly or jump into relevant tasks in the workflow, saving clicks and minimizing delays. Additionally, visual indicators highlight discrepancies, such as files that aren’t synchronized with the latest version, so users can resolve issues proactively.

Bridging the Gap Between High Performance and Productivity

It’s clear that SOLIDWORKS PDM isn’t just a file storage system; it’s a streamlined platform that connects data, processes, and people across engineering projects. With features like version control, advanced searches, automated workflows, and effective collaboration tools, PDM enables teams to consistently deliver work that’s not only precise but also efficient.

For engineering teams looking for a solution that simplifies data management without compromising detail or performance, SOLIDWORKS PDM offers unparalleled capabilities to transform your workflows.

Ready to get started? Contact our team today.

Related Articles

Is Bad Version Control Costing Your Engineering Team?

Non-CAD-Aware Cloud File Management Recommendations

The Real Costs of Poor Data Management

SOLIDWORKS PDM vs 3DEXPERIENCE CLOUD PDM: Workflows, Licensing & More

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.