Fused Deposition Modeling

A comprehensive guide to FDM 3D Printers and Materials

History of FDM

FDM 3D Printing Timeline

-

Replica of First Ever FDM 3D Printed Object

Year: 1988

In 1988, the first 3D Printed FDM (Fused Deposition Modeling) object created was a toy frog. It was made out of Polyethylene and Candle Wax in Scott Crumps garage as a suprise present for his daughter. Little did he know that he would be setting the foundation for Fused Depostion Modeling and the 3D Printing revolution.

-

-

Stratasys the Company is Launched

Year: 1989

In August of 1989 Stratasys the company was officially incorporated in the state of Delaware.

-

First Fused Deposition Modeling 3D Printer Sold

Year: 1992

In 1992, the first official Fused Deposition Modeling 3D printer was sold by Stratasys, aptly named the 3D Modeler.

-

Benchtop FDM 1500 3D Printer Released with QuickSlick Software

Year: 1993

In 1993, the second 3D printer product the Benchtop named the FDM 1500 was released to the public. Additionally, Stratasys begin to incorporate preprocessing software into their 3D Printers with the utilization of QuickSlice.

-

Stratasys Goes Public

Year: 1994

In October 1994, Stratasys went public with an IPO on the NASDAQ. Stratasys sold 1.38 million shares of common stock at $5 per share, netting approximately $5.7 million under the stock ticker SSYS.

-

Stratasys Buys IBM RP Technology

Year: 1995

In January of 1995, Stratasys invests more into Rapid Prototyping technology in the growing 3D printing industry by purchasing IBM RP technology. Later in 1995, the FDM 1500 3D printer was updated to the FDM 1600

-

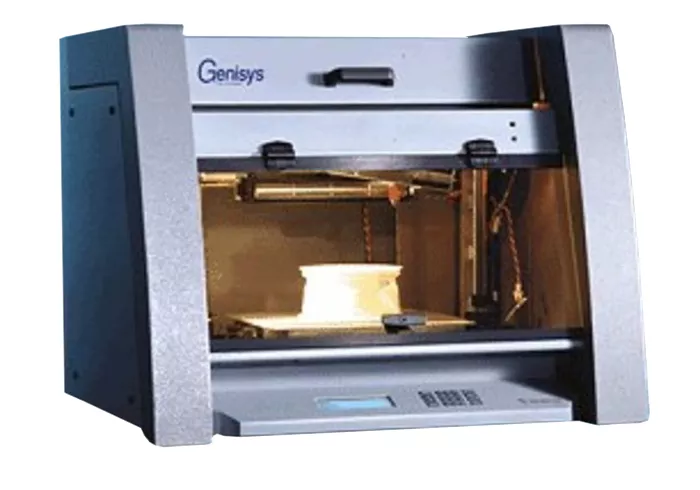

First FDM 3D Printer Priced under $50k

Year: 1996

In 1996, the resulting investment is Rapid technology led to the release of the Genisys 3D Printer, priced at $50K and the first ever 3D Printer to be priced under $100K. Later in 1996 the FDM 1650 3D Printer was released.

-

Benchtop 3D Printers Expanded

Year: 1997

In 1997, to expand on the Benchtop platform, an updated FDM 2000 and a larger FDM 8000 3D printer were released

-

Largest FDM 3D Printer Sold

Year: 1998

January 1998, Stratasys produces the largest 3D Printing platform system available on the market. Called the Quantum, that measured 84"x76"x39" inches in size. Due to build issues and only 150 units sold, the Genisys 3D Printer was retired in 1998.

-

New & Improved GenisysX 3D Printer Released

Year: 1999

In 1999 the new and improved Stratasys GenisysX 3D Printer was released. Also in 1999, the new FDM 3000 3D Printer with the innovative WaterWorks support material option was created and released.

-

FDM Maxum and Prodigy Desktop 3D Printer Introduced

Year: 2000

In 2000, Stratasys introduced the FDM Maxum was released, based off the Quantum technology but incorporated the WaterWorks support material. Additionally, an advanced preprocessing software tool called Insight is released and used for the Maxum platform. Additionally, Stratasy release the Prodigy desktop 3D printing system which was the entry into the desktop machines.

-

The Titan 3D Printer is Released

Year: 2001

2001, the Titan was born. This was the first Fused Deposition Modeling system capable of building with more advanced Thermoplastics like Polycarbonate, ABS, and Polyphenylsulfone or PPSF.

-

New Dimension 3D Printers at $30K Introduced

Year: 2002

February, 2002, the Dimension class machines were released to replace the older “Benchtop” units like the Genisys and FDM 3000. Priced at 30K, it was the least expensive RP system on the market. Also, a simplified pre-preprocessing software called Catalyst was created for the Dimension class machines.

-

Prodigy Plus 3D Printer Introduced

Year: 2003

In 2003, the Prodigy Plus FDM 3D Printer was released with both Insight software and WaterWorks support material. 2003 also saw the release of the Vantage class system which was a little brother to the Titan.

-

The Vantage 3D Printer Variations Released

Year: 2004

In 2004, three variations of the Vantage fused deposition modeling systems were introduced. Additionally, the Dimension SST 3D printer is released which brought soluble support capabilities to that FDM platform.

-

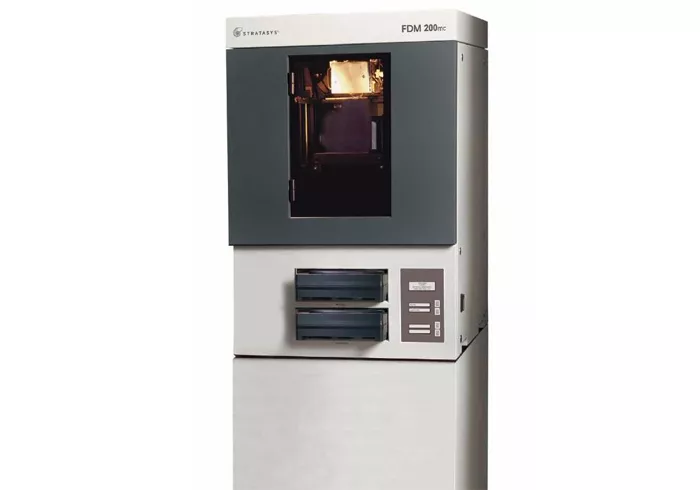

The FDM 200 3D Printer Released

Year: 2007

In 2007, the FDM 200 was released as an expansion of the high-end qualities for Stratasys products in a smaller footprint.

-

UPrint Product Released

Year: 2009

November 2009, the Stratasys uPrint 3D printer was released utilizing Fused Deposition Modeling technology.

-

Fortus 360/400 FDM 3D Printers Introduced

Year: 2010

In 2010, the Fortus 360/400’s Fused Deposition Modeling systems were created as an upgrade to the Vantage/Titan class machines.

-

Fortus 900 3D Printer Released

Year: 2011

In 2011, the Fortus 900 FDM was released to replace the Maxum 3D printing systems.

-

Stratays Purchases MakerBot

Year: 2013

2013, Stratasys bought Makerbot for a deeper dive into the desktop modeler FDM 3D printing market

-

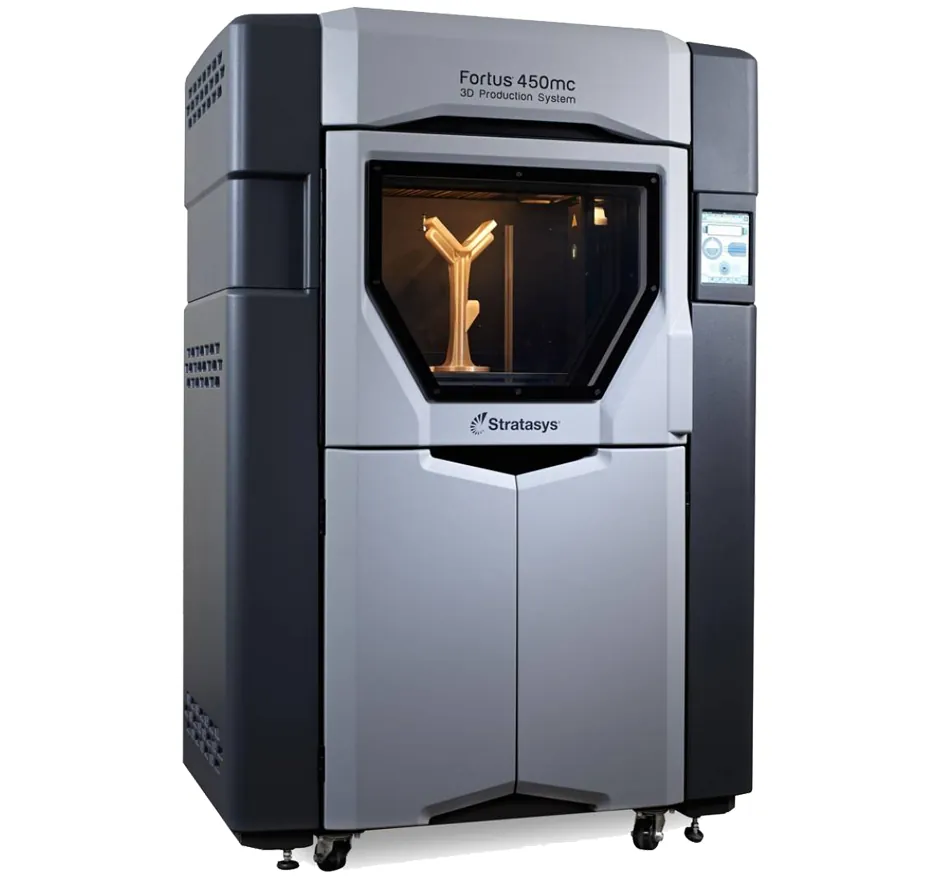

Fortus 360/400 Systems Upgraded to the 380/450 FDM 3D Printers

Year: 2014

2014 saw the upgrade from the Fortus 360/400 to the Fortus 380/450 class Fused Deposition Modeling machines.

-

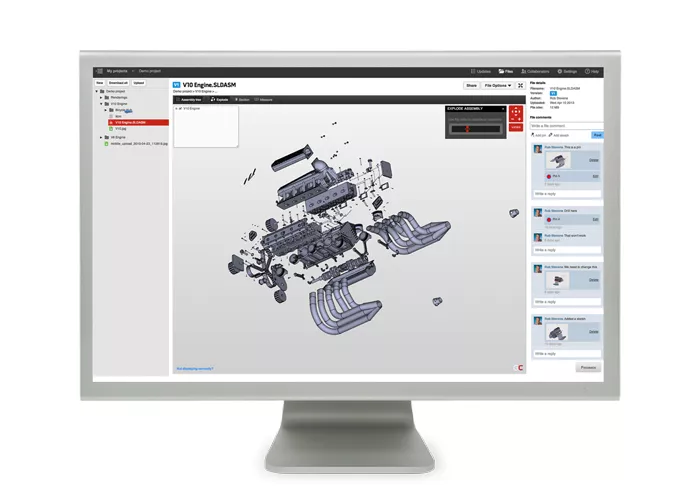

GradCAD Replaces Insight

Year: 2016

2016 Stratasys acquired GrabCAD Print software to replace and Insight (and others) as a pre-processing software tool.

-

Stratasys F-Series FDM 3D Printers Introduced

Year: 2017

In 2017, the new F-Series were released to include the F170, F270, and F370 FDM 3D Printers.

-

First Carbon Fiber 3D Printer Introduced

Year: 2018

In 2018, the Fortus 380CF was introduced as a specific Carbon Fiber designed system. Additionally, the Fortus 900 FDM 3D Printer was upgraded to the F900 system.

-

The F770 FDM 3D Printer Released

Year: 2021

In 2021, mixing the F-Series technology with the size of a 900, the F770 was released

-

The F190CF and F370CF Carbon Fiber 3D Printers Released

Year: 2022

2022, the new F190CF and F370CF machines are released for focus on Carbon Fiber 3D Printing material capabilities.

What is Fused Deposition Modeling (FDM) ?

Fused Deposition Modeling (also known as FDM ® ) is the most widely used additive manufacturing technique known for its extensive material selection, print accuracy, repeatability, and durability. Unique to Fused Deposition Modeling 3D printers, (unlike PolyJet , Stereolithography , or SAF technology), thermoplastic polymer is extruded from a small nozzle mounted to a CNC motion system, depositing material as toolpaths to trace the shape and infill of the part. Models are printed layer by layer from the bottom up, each fusing to the last until the part is complete. Stratasys FDM 3D printers build in a heated chamber to minimize part deformation and builds support structures as needed with a secondary Support material.

Why USe Fused Deposition Modeling?

FDM is the number one chosen technology for companies who need to produce reliable and durable parts, require large build envelopes, and who regularly prototype and test designs.

What is Fused Deposition Modeling used for?

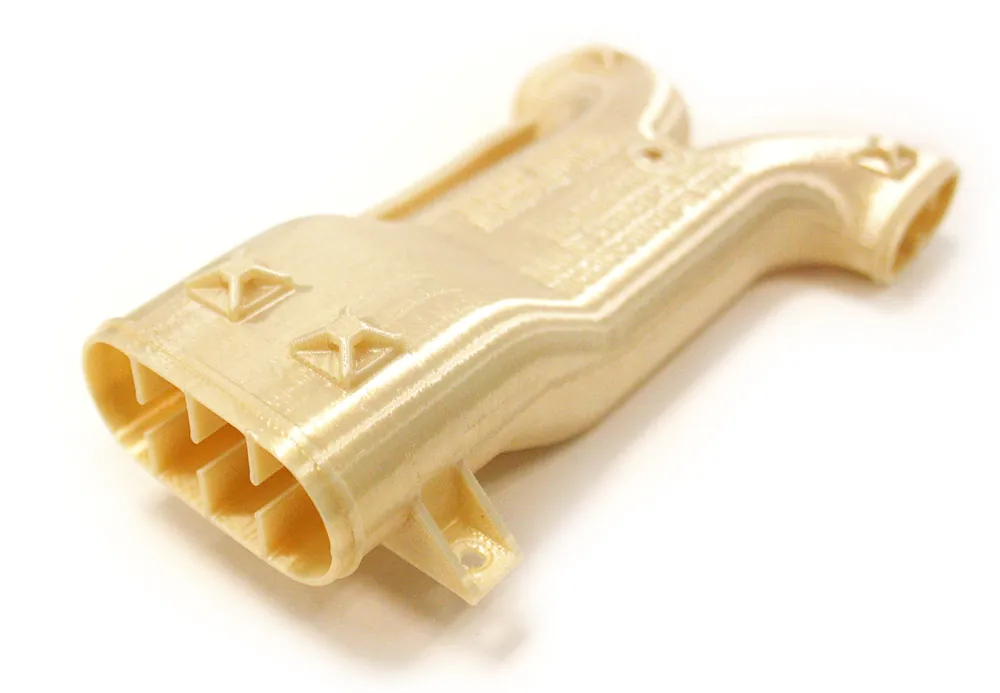

Concept Models

Fused Deposition Modeling was initially used to develop and design concept models for commercial industry applications. 3D printed parts provided designers with real-world, tactile objects to further explore and speed up the design process. As advancements in the technology progressed, concept models shifted into accurate and repeatable prototype development, giving design teams the opportunity to build and fully test ideas before sending parts to production.

functional Parts

FDM material properties like PPSF, Polycarbonate, and ABS opened the door to functional parts and those that mimicked injection molded parts for end-use applications. Soon after, chemical resistant materials like Nylon were made available for jigs, fixtures, and tooling applications for the manufacturing floor.

end-use Parts

New materials expanded and mechanical properties exploded with the use of ULTEM, Antero, and Nylon 12 CF, the age of Additive Manufacturing was born. Today, with properties similar to injection molded parts, in some materials, 3D printed objects are being used in short run productions and as end-use parts for a wide variety of industries.

Industries that Use FDM

Automotive

Dash CAE have used FDM technology for almost as long as the company has been established. With the superior strength characteristics from the PC materials and ULTEM™ 9085 resin, they are able to produce large motorsport parts for their customers, including the chassis, suspension and bodywork panels, which are used for complete functional aerodynamic testing. Read Case Study >>

Aerospace

BAE Systems has been using additive manufacturing over several years to support its “Factory of the Future” initiative, designed to leverage disruptive technologies and pave the way for future military aircraft production and maintenance operations.

Read Case Study >>

railway

France-based RUSTIN’s is a leader in the design, development, and production of advanced rubber and silicone sealing systems for an array of applications that ensure water or dust-proofness, airtightness, or noise isolation. The company’s solutions are particularly sought by those operating within the rail sector. Read Case Study >>

To help make the most informed decision of which FDM 3D Printer is best for you, take an in-depth look at the features included in each solution in our FDM Comparison Tool.

Contact GoEngineer directly for details on how FDM 3D Printing can help your design process.

Fused Deposition Modeling Materials

Stratasys FDM Materials

Want a sample part? Chat with an additive manufacturing expert to learn more about the best FDM materials for your needs or submit your own CAD model to be printed from our 3D Printing Services team.

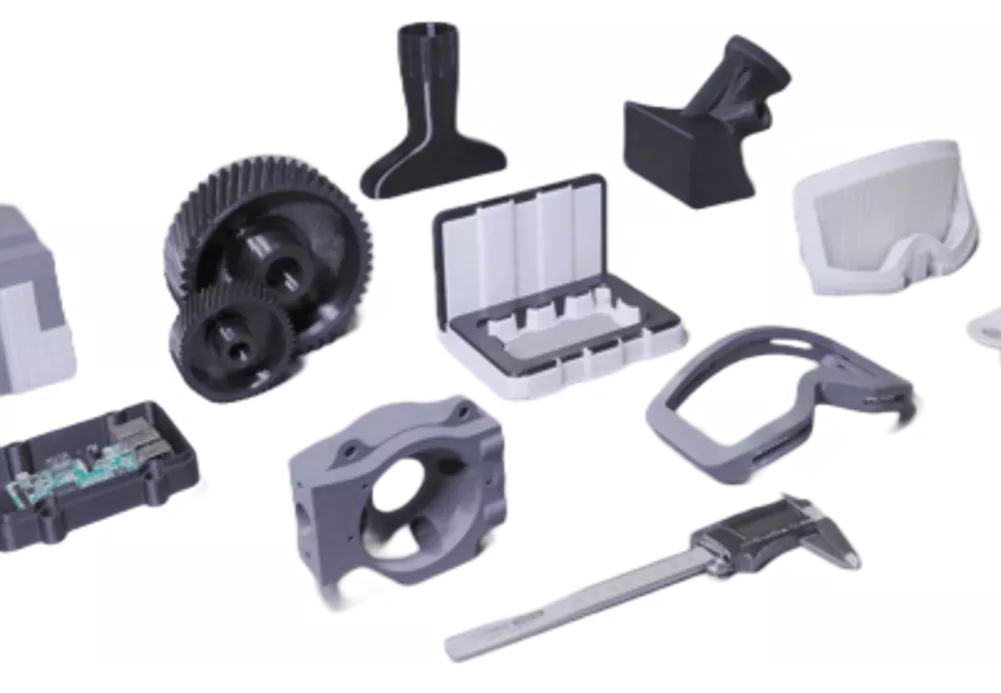

What are the Best Applications for FDM?

Fused Deposition Modeling is a 3D Printing technology suitable for nearly every application and industry. From aerospace, to automotive, manufacturing, medical and more; FDM has broad capabilities.

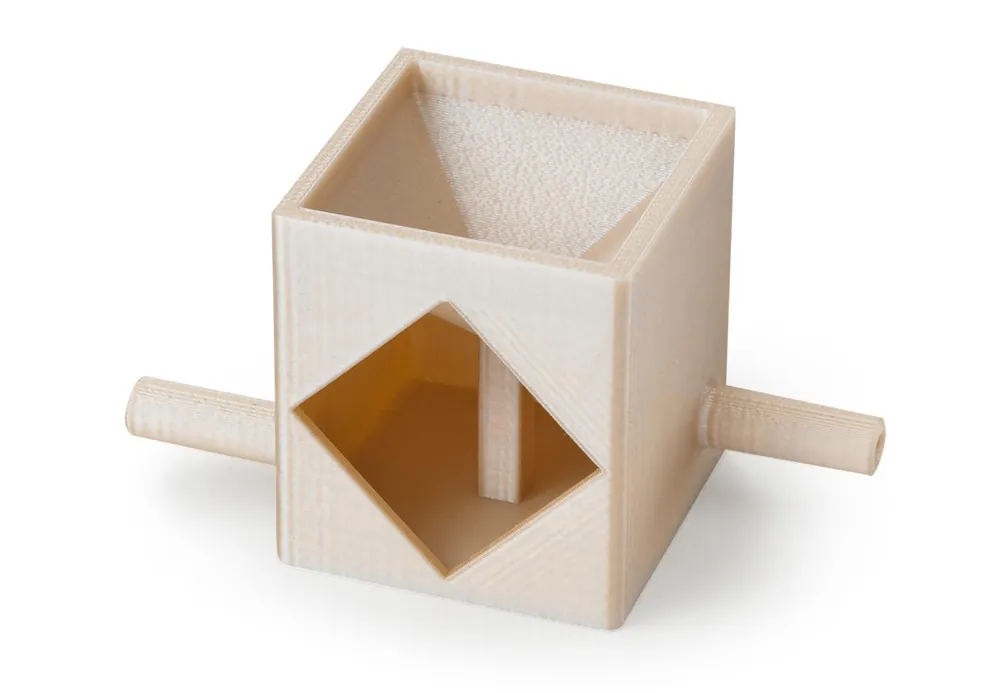

rapid prototyping

Rapid prototyping with 3D printing is the quickest and most cost-effective way to bring an idea to life. Quickly produce concept models to test new products or functional prototypes to validate performance early in the development process.

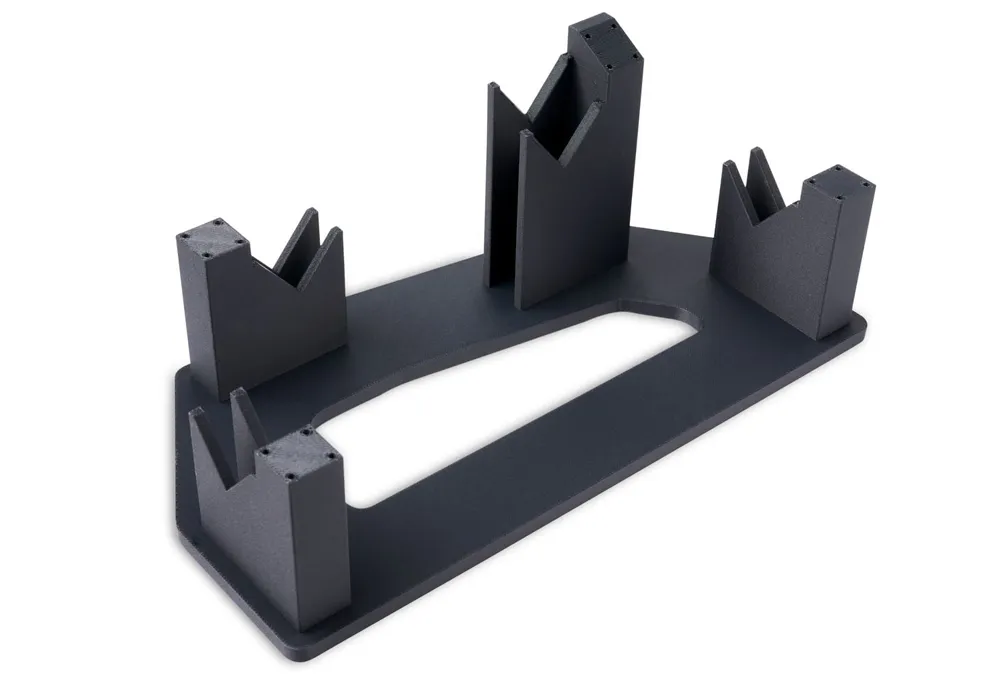

jigs & fixtures

3D printing jigs and fixtures when you need them is a convenient, safe, and cost-effective way to reduce development cycle times. An extensive library of durable materials opens new possibilities and meet manufacturing demands.

Composite tooling

3D printed composite tools are more cost-effective than traditional tool fabrication methods, and take a fraction of the time to produce. Sacrificial tools can be directly 3D printed to produce hollow and trapped-tool configurations, allowing design freedom without the need for complex tooling.

production parts

3D printing is a versatile option for on-demand production. Eliminating the need for long-lead and high-cost tooling, 3D printing is ideally suited to producing end-use parts for low-volume, high-complexity, and bespoke applications.

Advantages and Disadvantages of Fused Deposition Modeling

Very easy to use

- It’s the most widely copied (once the patents expired) style of 3D Printing on the market. Based on an extrusion process, using Thermoplastics, the technology can be easily operated and maintained.

Cost effective to run the machines and build the parts

- The raw materials are readily available

- Cost for the materials is lower than most

- Not a lot of expensive post processing required to get a part in hand

- The technology itself isn’t so overly extensive that it’s unaffordable

Repeatable

- FDM is very stable, as are the materials, allowing for consistently repeatable part generation

Accurate

- In the Stratasys temperature-controlled units, between the precisely monitored extrusion temperatures and steadily maintained oven temp, the two in conjunction with each other can effectively control material shrinkage which enables the machines to build very dimensionally accurate parts.

Large array of real-world plastics

- Unlike some technologies that have materials that “mimic ABS” or have “polypropylene like” properties, (for example) FDM uses the same industries specific materials like ABS, PC, ULTEM, and Nylon, just to name a few. Doing this allows for users to already know how a material will behave and therefore enhancing the use of the technology.

Office Friendly

- The FDM process is an extremely clean and environmentally friendly technology that can quickly and readily be installed in an office environment. Due to the nature of the process, no special venting is required, the materials can be recycled, and a finished product can be immediately handled as there’s no concerns over post curing of a toxic chemical like other technologies. Long story short, it’s a very clean 3D Printing technology.

It can be slow

- Depending on the geometry and the layer resolution selected, this technology can be slower to build a part (multiple parts) than others out there. In the realm of production uses, other companies/3D Printing styles are a better fit.

Layer bonding

- FDM (by Stratasys with a specifically heated build chamber) has a really good layer bonding (close to injection molded part strength which is marked as the industry standard) in the XY plane. However, most of the materials will max out at around 70% bonded strength in the XY to Z plane. (Some of the Nylons will get into the 80% range) Point being, FDM doesn’t create an isotropic bond, layer to layer, and therefore can be weaker in the Z plane.

Multiple materials

- As the technologies expand, the desire for a machine to build in multiple materials has grown. After 30 years of development, FDM has primarily stayed true to a single material build style.

Resolution

- FDM has long been criticized for it’s “layer lines”, due primarily to the nature of the technology and the layer resolutions upon which those layers are created. Stratasys, systems range from .005” to over .040” in resolution where some resin systems will get down to .0006” per layer and almost completely eliminating the layer line effect.

Color

- Due to the fact that FDM is a single material system, that will then therefore lead it to also be a single-color system.

What are the Best FDM 3D Printers?

Selecting the best Fused Deposition Modeling 3D printer depends on your company’s specific needs and use case. What material properties do you need to create, test, or validate your products? What applications do you plan on printing now or in the foreseeable future? What are your turnover times? What is your budget? How much space does your office building or factory have available to house a 3D printer? All of these questions are important to consider when bringing 3D printing in-house.

-

-

F123 Series

- Common Applications:

- Prototyping

- Jigs & Fixtures

- Education

- Production Parts - Benefits

- Efficient & accurate

- Office friendly

- Large build size

- Multiple material options -

Materials*: ABS - CF10 , ABS-ESD7 , ABS-M30 , ASA , DIRAN , Nylon CF10 , TPU 92A , PC-ABS , and PLA

*Material option based on F123 Series printer

-

-

Fortus 450

- Common Applications:

- Prototyping

- End-use parts

- Jigs, fixtures, and workholding

- Production Parts - Benefits

- 13 material options

- Accurate and repeatable

- Large build size

- 16" x 14"x 16" build envelope -

Materials: ASA , ABS-M30 , PC-ABS , PC , Nylon 12 , ST-130 , ULTEM 1010 , ULTEM 9085 , Nylon 12CF , ABS-M30i , ABS-ESD7 , PC-ISO , Antero 840CN03 , and Antero 800NA

-

-

f770

- Common Applications:

- Jigs & Fixtures

- End-use parts

- Prototyping - Benefits

- Affordable, large scale printing

- Easy to operate

- Reliable and consistent performance

- 39.4" x 24" x 24" build envelope

-

-

F900

- Common Applications:

- Prototyping

- Manufacturing Tooling

- Production Parts - Benefits

- Extensive material options and versatile material performance

- Built for demanding applications

- Delivers consistent and repeatable results

- 36 x 24 x 36 in build envelope -

Materials : ASA , ABS-M30 , ABS-M30i , ABS-ESD7 , PC , PC-ABS , PC-ISO , Nylon 6 , Nylon 12 , ST-130 , PPSF/PPSU , Ultem 1010 , Ultem 9085 , Nylon 12 CF , Antero 800NA , and Antero 840CN03

-

-

F3300

- Common Applications:

- Tooling / Jigs and Fixtures

- Obsolete Part Replacement

- Prototyping - Benefits

- Integrated material dryers

- Precise gantry control

- Advanced extruder control

- 23.6 x 23.6 x 31.5 in build envelope -

Materials : ASA , PC , Ultem 9085 , and Nylon 12 CF

-

-

Makerbot

- Common Applications:

- Prototyping

- Production Parts

- Tooling - Benefits

-Industrial-quality 3D printing

- Carbon fiber cabilities

- 6-in-1 Modular Performance Extruders

- 6" x 7.5" x 7.75" (dual extrusion) 7.5" x 7.5" x 7.75" (single extrusion) build volume -

Materials : PLA, ASA, Stainless Steel, Tough, PETG, PC-ABS, PC-ABS FR, PVA, Nylon Carbon Fiber, Nylon, CR-30. Learn More >>

What are the Best FDM 3D Printers?

There are many 3D printers on the market – some are desktop friendly or compact enough to fit well in small office spaces – while others are industrial-sized, best suited for large parts or demanding production times. Selecting the best Fused Deposition Modeling 3D printer depends on your company’s specific needs and use case. What material properties do you need to create, test, or validate your products? What applications do you plan on printing now or in the foreseeable future? What are your turnover times? What is your budget? How much space does your office building or factory have available to house a 3D printer? All of these questions are important to consider when bringing 3D printing in-house.

F123 Series

For a full list of products available and answers to some commonly asked questions, click the button below.

Fortus 450

For a full list of products available and answers to some commonly asked questions, click the button below.

F770

For a full list of products available and answers to some commonly asked questions, click the button below.

F900

For a full list of products available and answers to some commonly asked questions, click the button below.

MakerBot

For a full list of products available and answers to some commonly asked questions, click the button below.

Examples of Fused Deposition Modeling

Choosing a SOLIDWORKS License Option

When you are ready to purchase, there are two different SOLIDWORKS licensing options that give you the ability to buy or rent SOLIDWORKS products. Those licensing types include term licenses and perpetual licenses.

What is a SOLIDWORKS Term License?

SOLIDWORKS term licenses offer a short-term commitment with the flexibility to match your workload and expenses. They are available to rent in increments of 3 months or 1 year. Term licenses offer a considerably lower upfront initial investment that is attractive to startups or freelancers as well as to people who want to buy SOLIDWORKS for personal use.

For a full list of products available for term licensing and answers to some commonly asked questions, click the button below.

AsK a GOENGINEER EXPERT

Still Have Questions About Fused Deposition Modeling?

Reach out to GoEngineer and an expert will follow-up with you.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services