Design to Manufacture: SOLIDWORKS Tools to Help Bridge the Gap

Analyze. Evaluate. Check. Compare.

These are all words used to describe digging further into our designs to not only verify the functional needs of its intended use but also its manufacturability and cost to manufacture. In terms of SOLIDWORKS, I have grouped the tools available to assess manufacturability and cost to manufacture into four categories:

- Utilities

- DFMXpress

- Evaluation Tools

- Costing

SOLIDWORKS Utilities

Geometry Analysis & Geometry Check

Geometry Analysis identifies geometric entities in a part that could cause a problem in other applications. Machining a part with these types of geometric faces, edges, and points can be problematic. A quick change, such as a fillet or combining multiple faces with a delete and patch can make the machining operation much easier or even cheaper.

Geometry Check is a similar tool that allows you to find other useful geometry conditions such as the minimum radius of curvature (This helps to understand tool diameter needs in machining), edge gaps, and vertex gaps.

Thickness Analysis

Choose a target thickness of a part and the Thickness Analysis tool will highlight the thick and thin regions of the part. Helpful when doing some first-pass plastics analysis, you can even save the highlights and data out as a report.

Symmetry Check

Symmetry Check identifies symmetrical, asymmetrical, and unique faces based on a selected plane and will also automatically split the part on that plane if desired.

Compare

The compare utility compares two documents based on either properties, features, geometry, and Bill of Materials. Depending on the type of compare performed, you are presented with a table of values with their differences or the two models highlighted with their differences.

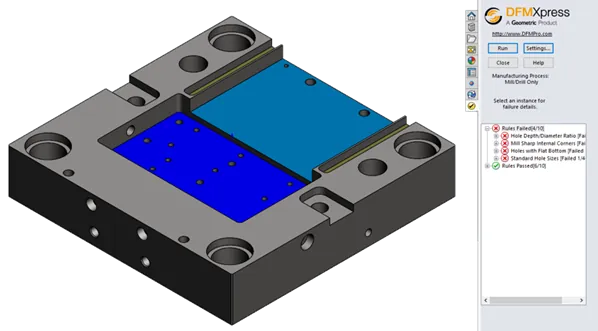

DFMXpress

DFMXpress is an analysis tool that validates manufacturability based on Drill, Mill, and Turn rules as well as rules specific for sheet metal, standard hole sizes, and injection molding. After configuring the rule parameters and manufacturing process, the tool is run and both passed and failed are listed and can be cross-highlighted onto the model.

Evaluation Tools

Zebra Stripes

Zebra stripes primarily let you see curvature between multiple faces. Similar to parking your car under the bright lights of a gas station at night, zebra stripes simulate the reflection of long stips of light on a shiny surface.

Curvature

With the curvature tool, you can render your model with colors corresponding to the curvature value (1/Radius) at that point on the face.

Draft, Parting Line & Undercut

Helpful in mold design, the draft, parting line, and undercut analysis tools allow you to choose a direction of pull and visually evaluate areas with insufficient draft, find the best path for your parting line, and identify areas that need side cores or design changes.

Costing

SOLIDWORKS Costing (included in SOLIDWORKS Professional for parts and SOLIDWORKS Premium for assemblies) enables you to create costing templates specific to your business and processes for Sheet Metal, Machining, and Weldments. You then run the costing tool against your parts or assemblies to get a much closer estimate of cost.

Whether you’re analyzing, evaluating, checking, or comparing being aware of the SOLIDWORKS tools that are at your disposal is key to being able to reduce mistakes, have fewer iterations heading to the shop floor, or just having a more nuanced understanding of your designs.

Expand Your SOLIDWORKS Skillset

SOLIDWORKS 2021 Enhanced Graphics Performance

Easily Save Configurations as Separate Parts

Linking a Custom Cut List Property to a SOLIDWORKS Drawing Balloon

About Greg Dawes

Greg Dawes is an Application Engineer at GoEngineer who is a Certified SOLIDWORKS Expert and an Elite Application Engineer. He is a Purdue University graduate with a Bachelor’s Degree in Computer Graphics Technology. Greg has been in the SOLIDWORKS Reseller channel since 2010. Outside of work, Greg enjoys his time in Northeast Indiana on a lake with his wife Ashley, daughter Mackenzie, and three dogs Riley, Felix, and Auggie.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.