FEA SERVICES

High-End Engineering Analysis On-Demand

Performance Prediction You Can Rely On

The GoEngineer simulation team provides a wide range of FEA consulting services to solve design issues, hit performance targets, shorten length iteration cycles, and ensure smooth a prototyping phase.

Our FEA services are the fastest and easiest way to access industry-leading FEA technology, run on enterprise computing resources, by analysts with decades of software and industry experience.

Whether you need additional support for your own simulation team or are looking for a total end-to-end analysis solution, GoEngineer is here to help.

Predict Complex Scenarios

Get nonlinear, dynamic, and multi-physics analyses for complex product performance and manufacturing problems.

Avoid Overdesign

Improve product performance while maintaining material efficiency, through one-off or automated design study.

![]()

Solve Problems Faster

Enterprise computing and FEA specialization reduce simulation time and increase accuracy.

“BraunAbility is pleased to partner with GoEngineer for all our FEA tasks. The main reason we did this several years ago and continue to collaborate with GoEngineer, it’s not only their capability and expertise, but the technical and account management team's dedication to always providing us the attention we need, in a very timely manner.”

– Carlos B.

Sr Director, Vehicle Engineering

BraunAbility

OUR FEA SERVICE Portfolio

-

Static Analysis

- Quality stress and displacement analysis requires excellent attention to detail, high-density FEA models, accurate materials and contact behavior, and an experienced Abaqus analyst to set it all up to converge well.

- Key capabilities:

- Linear & non-linear

- Stress, strain, deformation

- Buckling

- Contact & sealing

- Material fracture & hyperelasticity - Ideal for:

- Basic or in-depth understanding of load capacity and stiffness.

- High detail and accuracy in stress and contact behavior. -

-

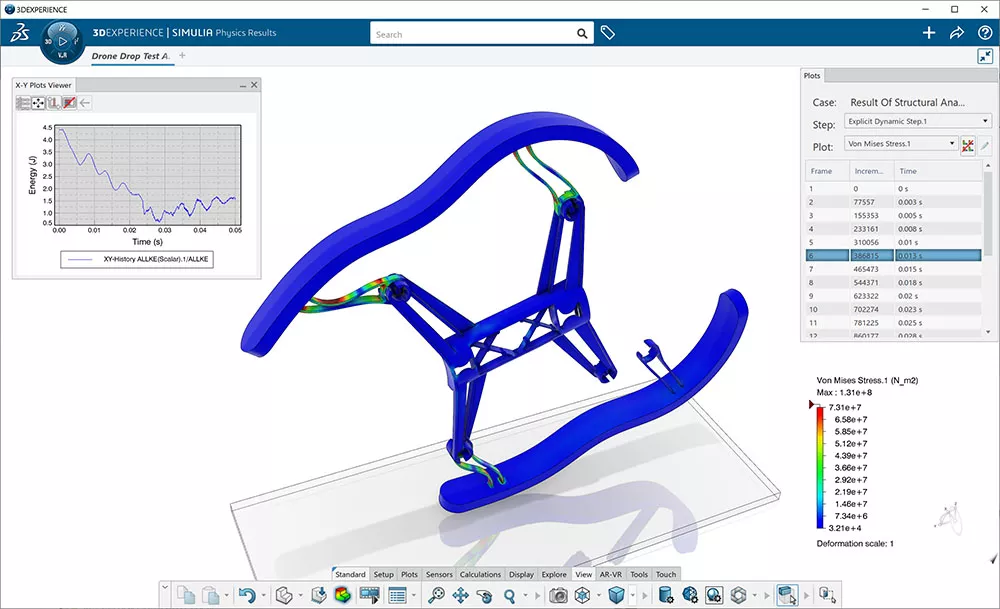

Explicit Dynamic Analysis

- When high-speed and chaotic events exceed the capabilities of static analysis, an explicit solver with sufficient computing resources can provide an answer to even the largest problems.

- Key capabilities:

- Quasi-static

- Impact & drop

- Crash (including full-vehicle)

- Ballistic & mechanical shock - Ideal for:

- Predicting assembly and material behavior in high-energy, transient events.

- Efficiently analyzing scenarios involving large deformation, unconstrained bodies, and/or complex interactions. -

-

Vibration Analysis

- Vibration is a critical part of structural and acoustic analyses. The more advanced procedures may require test data or high-performance computing (HPC), and results may be used for further downstream simulation.

- Key capabilities:

- Modal (normal modes – eigenvalue extraction)

- Random vibration

- Frequency response

- Steady-state dynamics

- Acoustics - Ideal for:

- Understanding response to various types of excitation for structural, acoustic, comfort, and other concerns. -

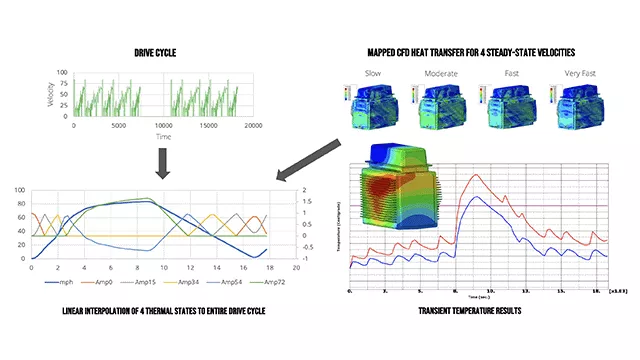

Thermal Analysis

- Temperature effects are of huge concern to mechanical and electromagnetic analysts. Heat’s effects on materials and transfer through the system is a complex multiphysics problem, potentially requiring capability in multiple software solutions.

- Key capabilities:

- Steady-state & transient

- Coupled thermal-stress analysis

- Heat transfer

- Coupled structures, fluids, and electromagnetics - Ideal for:

- True understanding of operational conditions when temperature effects are significant. -

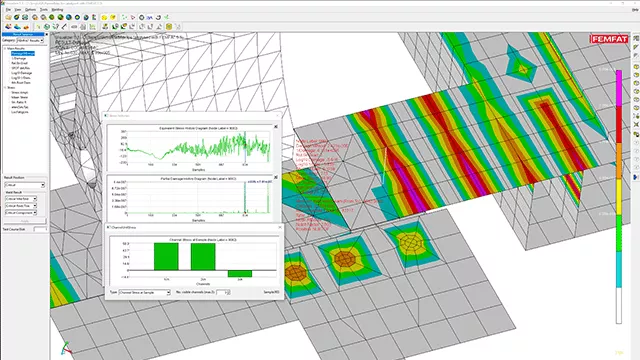

Durability Analysis

- Long-term durability of products is enormously important to human safety and to company reputation. Effective analysis requires sophisticated tools to handle sensitive material models in complex and cumulative loading scenarios.

- Key capabilities:

- Life cycle prediction

- Fatigue & creep damage

- Safety factors

- Base material, weld, or spot joint fatigue

- Crack prediction - Ideal for:

- Ensuring long-term durability in all intended operational conditions, especially in lightweight design and materials. -

-

Multibody Dynamics

- Multibody dynamics is essential for understanding assembly behavior and loading in motion, verifying clearances, providing loads for downstream analysis, and more.

- Key capabilities:

- Kinematic/dynamic motion studies

- Flexible body interface with Abaqus

- Vehicle dynamics & durability

- Realtime ADAS simulation - Ideal for:

- Ensuring assembly motion is viable as intended.

- Providing input data for structural FEA. -

-

Manufacturing Analysis

- Simulation can be used on more than just product performance. When used on manufacturing processes, there's the opportunity to eliminate extremely costly retool and redesign efforts.

- Key capabilities:

- Metal forming

- Plastic injection molding (fill, pack, warp) - Ideal for:

- Ensuring product manufacturing will succeed before tooling. -

-

Multiphysics

- Accurate product performance prediction, in many cases, must account for multiple kinds of physics. Pulling that off in FEA may require advanced skills, multiple solutions and workflows, and familiarity with the quirks of putting it all together.

- Key capabilities:

- Coupled eulerian-lagrangian

- Hydrostatic-fluid-mechanical

- Fluid-structure interaction

- Piezoelectric

- Structural acoustics - Ideal for:

- True understanding of operating conditions when fluids, structures, and electromagnetism act interdependently. -

-

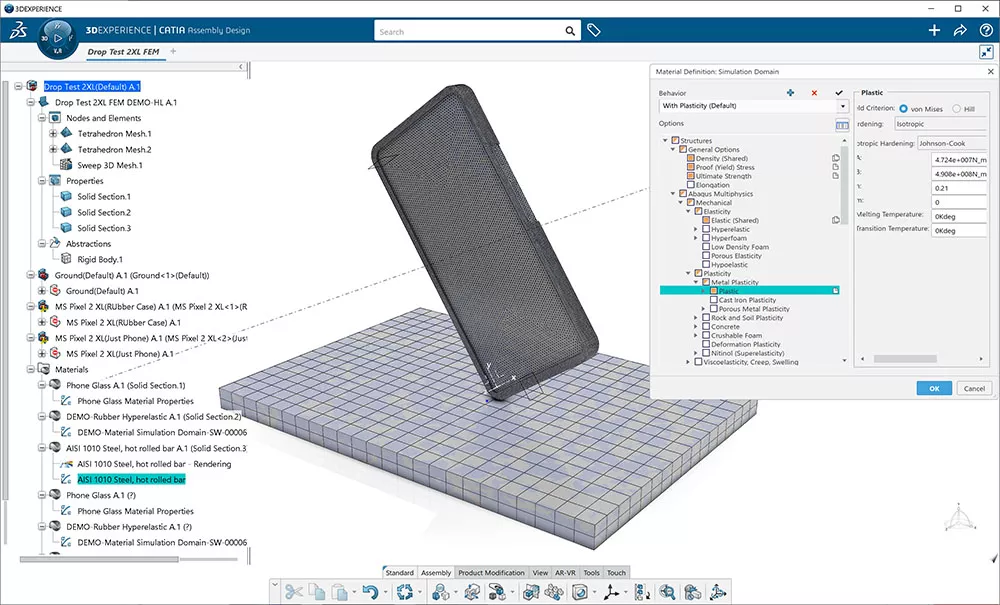

Material Calibration

- Virtual prototyping is the level of simulation we all aspire to, but it can only be that accurate with correct material models. We have the tools and experience to get that data and conduct those simulations.

- Key capabilities:

- Material evaluation

- Material model development - Ideal for:

- Building virtual prototyping methodologies by incorporating real-world data specific to you. -

-

Design Optimization

- One of the most powerful applications of FEA is the use of automated simulation to guide design parameters or even topology. With the right tools and careful model setup, a sophisticated analysis loop and iterate toward the ideal design within the requested constraints.

- Key capabilities:

- Topology, shape, & bead optimization

- Parametric optimization

- Design of experiments - Ideal for:

- Generating or altering designs to meet multiple specific performance targets with maximum efficiency. -

Our Process

Consultation

It Begins with a Conversation

Your engineering and business needs are unique, and there are many ways that GoEngineer can help. We can integrate simple analysis, design experimentation, and virtual testing involving a variety of physics simulation at varying levels into your own processes and operations.

After an in-depth technical discussion, we'll provide the best personalized solutions from our service catalog to meet your goals.

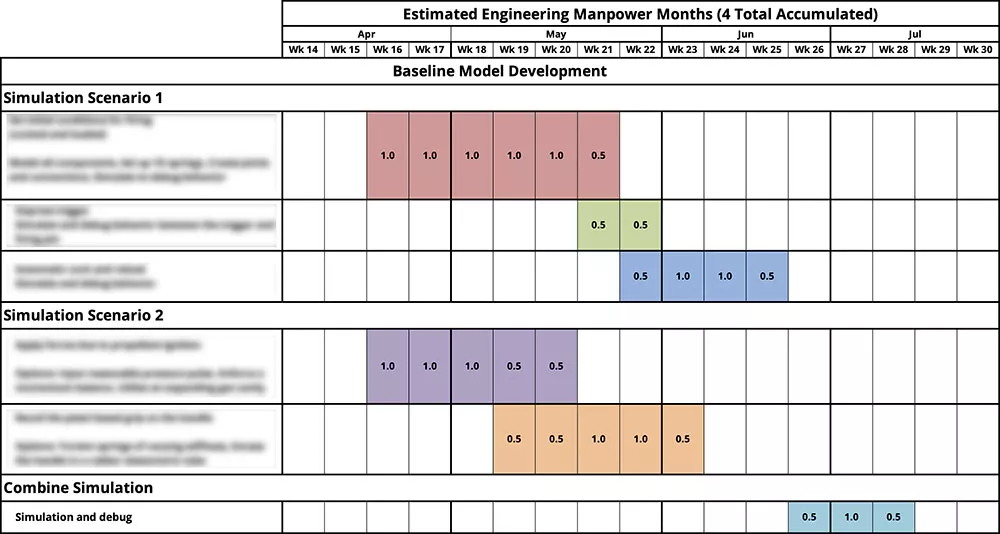

Proposal

Know Exactly What You’re Getting

GoEngineer will build a detailed proposal reiterating your interests and what we’ll do to meet them. This document will include:

- Bulleted project scope, including analysis methods, purposes, and outputs

- Phased timeline and manpower (estimated)

- List of deliverables, obligations, and extended offerings

- Cost breakdown

Communication

Dedicated Points of Contact

You will have a lead engineer and an overseeing engineering manager assigned to your project, with uninterrupted and open lines of communication.

Awareness from Beginning to End

We recommend weekly web meetings with your GoEngineer project lead and engineering manager to discuss the progress and direction of your project. These meetings can be extremely valuable, especially upon surprising analysis results.

Have CAE, Will Travel

GoEngineer personnel are also available for travel to in-person meetings with you and/or your customer.

Execution

Know Exactly What You’re Getting

We build high-quality simulations to customer specifications using our extensive CAE software portfolio, chiefly consisting of Dassault Systèmes solutions:

- Abaqus FEA

- fe-safe

- Tosca Structure

- Isight & SIMULIA Execution Engine

- FEMFAT Fatigue Software

- Simpack

- SOLIDWORKS Simulation

- SOLIDWORKS Flow Simulation

- SOLIDWORKS Plastics

- 3DEXPERIENCE STRUCTURAL

- 3DEXPERIENCE FLUIDS

- Ask for additional codes

Big Computing Resources for Fast Results

With high-performance local and cloud computing capabilities, we can support rapid iteration on very large analyses, like high-fidelity, multistep nonlinear static analysis, or full vehicle crash simulations.

Deliverables

Everything You Need for Better Decision Making

The GoEngineer CAE consulting team can produce a wide range of deliverables for you, as scoped out in your proposal:

- Simulation and technical presentations

- Image, video, and 3D interactive results

- Optimized 3D topology or design parameters

- Design/engineering recommendations

- Accounting of resources

- Functioning FEA & CFD models

- Solver output databases

- Documentation of methodologies

Next Steps

Building Upon Success

Some projects may be complete upon delivery, but it doesn’t have to stop there. Additional steps may include:

- Project retrospective

- Customer interface

- Additional iterations and studies

- Transfer of analysis files

- Training in methodologies used

Learn More

Blog Article

8 Ways Working with an FEA Consultant Improves Your Bottom Line

As advanced simulation software like Abaqus becomes ever more important to developing highly competitive products, manufacturers are looking for ways to expand their FEA capabilities. Many of those manufacturers may begin by looking to hire FEA or CFD or emag simulation engineers, but this may not be the most cost-effective approach.

Blog Article

How the GoEngineer Simulation Team Is Expanding Customer Capabilities

GoEngineer's simulation team can best be demonstrated by introducing some of the individual members. If your company needs simulation support, these are among the people ready to assist you.

GoEngineer Consulting

CFD Services

Our CFD services are the fastest and easiest way to access cutting-edge Navier-Stokes, Lattice-Boltzmann, and multiphysics CFD solutions on serious HPC resources, with the experience to do the analysis right.

Our team can help at any level, from augmenting your own CFD group to completely CFD analysis, in traditional or custom methodologies.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services